Preparation method of boron nitride nanotube hydrophobic membrane

A technology of boron nitride nanotubes and hydrophobic membranes, applied in chemical instruments and methods, nitrogen compounds, nanotechnology, etc., can solve the problems of many impurities, inability to form films, low concentration, etc., and achieve simple process, high yield, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

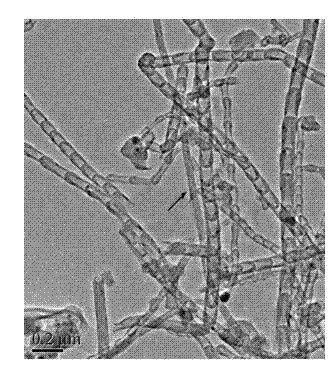

[0016] Specific embodiment one: In this embodiment, the method for preparing a boron nitride nanotube hydrophobic membrane based on a stainless steel substrate includes the following steps:

[0017] (1) Seal the raw material amorphous boron powder and several stainless steel balls into a stainless steel ball mill tank, place them in a horizontal ball mill for ball milling, the mass ratio of ball milling balls to raw materials is 80:1, and the ball milling is carried out under an argon atmosphere. The pressure of the ball mill jar was filled to 240kpa, and ball milling was continued at room temperature for 150 hours at 110 rpm.

[0018] (2) After ball milling, place the sealed jar in a glove box filled with nitrogen to take out the boron powder. After ball milling, boron powder is dissolved in ethanol organic solvent together with catalyst ferric nitrate under nitrogen atmosphere, the mass ratio of catalyst to boron powder is 0.07:1, the molar concentration of raw materials dis...

specific Embodiment approach 2

[0026] Embodiment 2: This embodiment differs from Embodiment 1 in that the ball mill described in step (1) is a vertical ball mill. Others are the same as in the first embodiment.

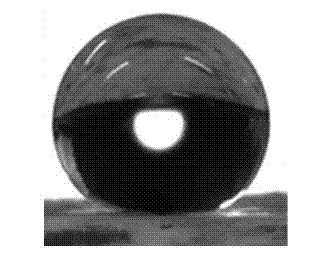

[0027] The nanotubes prepared in this embodiment have a length of about 30 μm and a diameter ranging from 150 to 250 nm. The contact angle measurement results reached the superhydrophobic standard, and the water droplet contact angle reached 161°.

specific Embodiment approach 3

[0028] Embodiment 3: The difference between this embodiment and Embodiments 1 and 2 is that the ball milling in step (1) is carried out under an ammonia atmosphere. Others are the same as the first and second embodiments.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Water droplet contact angle | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com