Sea urchin-like boron nitride nanosheet-nanotube hierarchical structure and preparation method thereof

A hierarchical structure, boron nitride technology, applied in chemical instruments and methods, nitrogen compounds, nanotechnology, etc., can solve problems such as sea urchin-like boron nitride nanosheet-nanotube hierarchical structure, etc., to achieve uniform morphology, Good oxidation resistance and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A sea urchin-like boron nitride nanosheet-nanotube hierarchical structure is prepared by the following method:

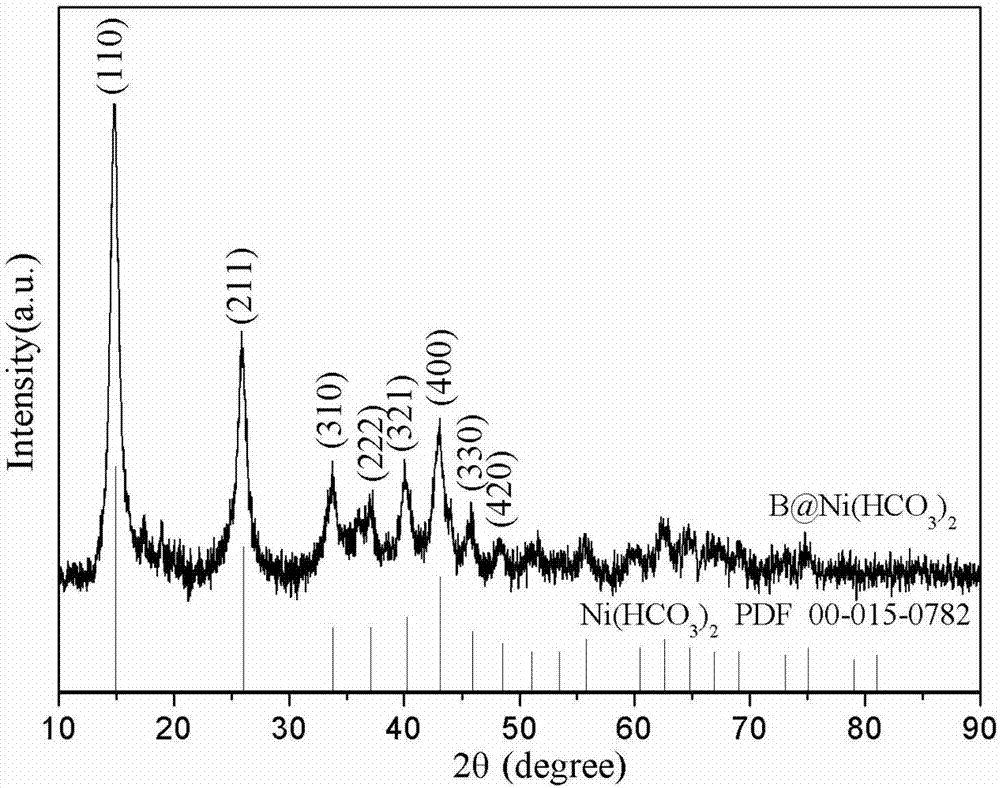

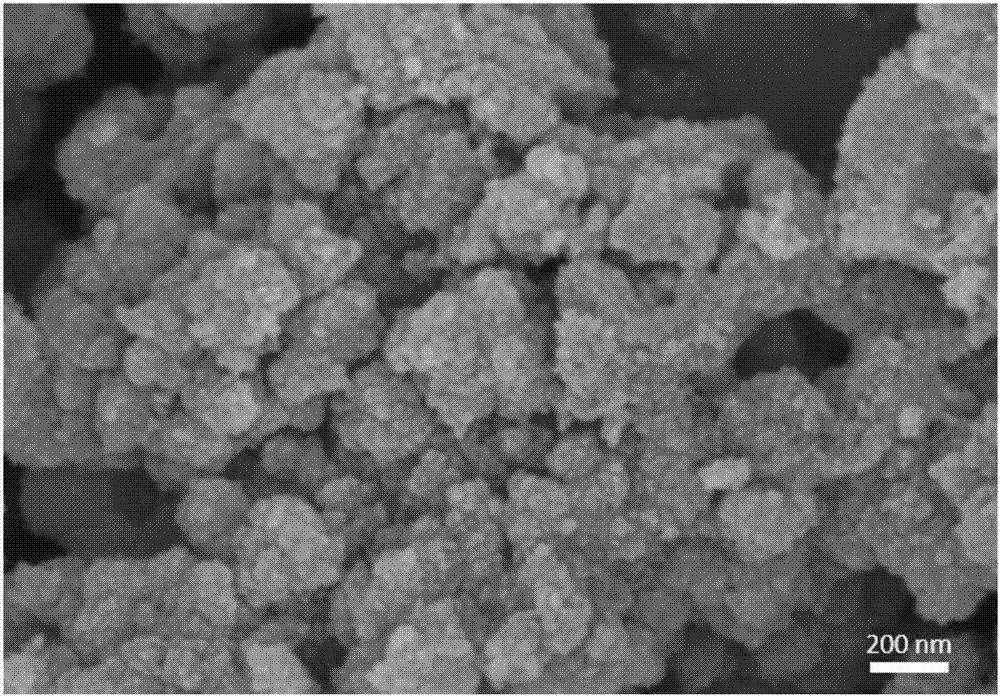

[0031] (1) Preparation of B@Ni(HCO 3 ) 2 Precursor: Add 0.05g of polyvinylpyrrolidone K30, 0.1mol of amorphous boron powder and 0.01mol of nickel nitrate in 100ml of deionized water, stir magnetically and ultrasonically, then add 0.2mol of ammonium carbonate to the above solution and place it at a constant temperature of 60°C Stir magnetically in a water bath for 12 hours and filter; the filtrate is washed with water and dried in vacuum at 60°C for 12 hours to obtain B@Ni(HCO 3 ) 2 Precursor.

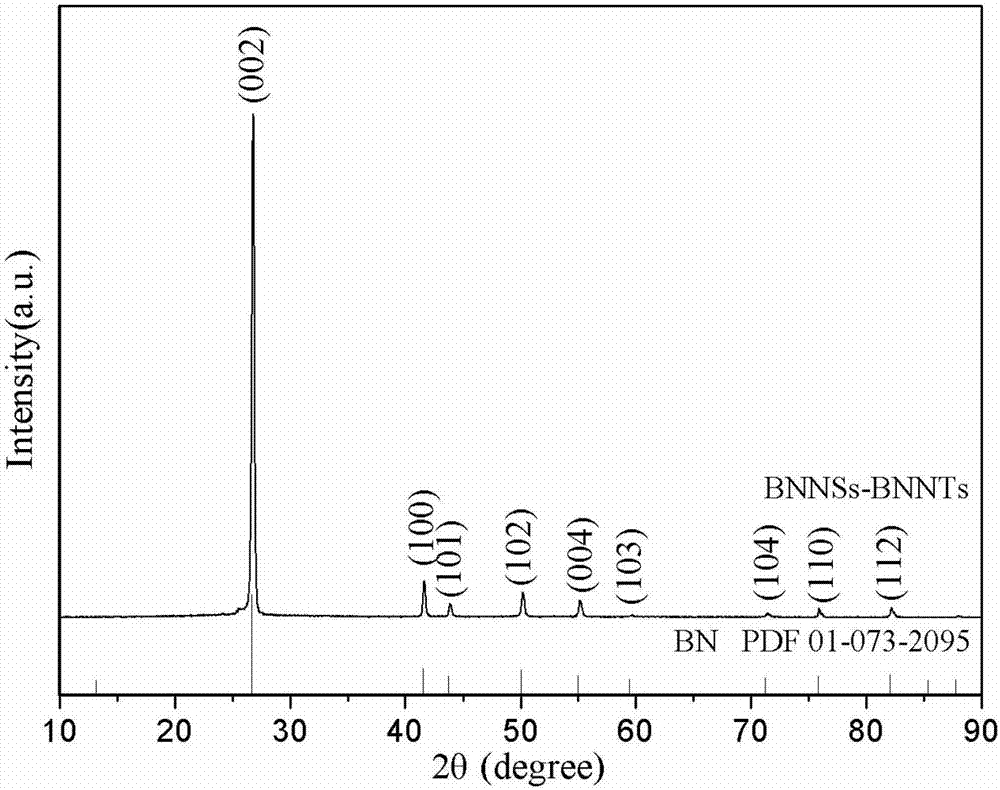

[0032] (2) Preparation and purification of sea urchin-like boron nitride nanosheet-nanotube hierarchical structure: B@Ni(HCO 3 ) 2 The precursor was placed in a vacuum tube furnace. In an ammonia atmosphere with a flow rate of 50ml / min, the temperature was raised from room temperature to 1100°C at a rate of 10°C / min, and kept for 1h; then the temperature was conti...

Embodiment 2

[0035] A sea urchin-like boron nitride nanosheet-nanotube hierarchical structure is prepared by the following method:

[0036] (1) Preparation of B@Ni(HCO 3 ) 2 Precursor: add 0.5g of polyvinylpyrrolidone K30, 0.1mol of amorphous boron powder and 0.05mol of nickel nitrate in 100ml of deionized water, stir magnetically and ultrasonically, then add 0.5mol of ammonium bicarbonate to the above solution and place at 70°C Magnetically stirred in a constant temperature water bath for 6h, filtered; the filtrate was washed with water and vacuum dried at 60°C for 12h to obtain B@Ni(HCO 3 ) 2 Precursor.

[0037] (2) Preparation and purification of sea urchin-like boron nitride nanosheet-nanotube hierarchical structure: B@Ni(HCO 3 ) 2 The precursor was placed in a vacuum tube furnace. In an ammonia atmosphere with a flow rate of 100ml / min, the temperature was raised from room temperature to 1100°C at a rate of 15°C / min, and kept for 2 hours; then the temperature was continued at a ra...

Embodiment 3

[0040] A sea urchin-like boron nitride nanosheet-nanotube hierarchical structure is prepared by the following method:

[0041] (1) Preparation of B@Ni(HCO 3 ) 2 Precursor: Add 0.1g of polyvinylpyrrolidone K30, 0.1mol of amorphous boron powder and 0.01mol of nickel nitrate in 100ml of deionized water, stir magnetically and ultrasonically, then add 0.3mol of ammonium bicarbonate to the above solution and place at 80°C Stir magnetically in a constant temperature water bath for 3 hours and filter; the filtrate is washed with water and dried in vacuum at 60°C for 12 hours to obtain B@Ni(HCO 3 ) 2 Precursor.

[0042] (2) Preparation and purification of sea urchin-like boron nitride nanosheet-nanotube hierarchical structure: B@Ni(HCO 3 ) 2 The precursor was placed in a vacuum tube furnace. In an ammonia gas atmosphere with a flow rate of 150ml / min, the temperature was raised from room temperature to 1100°C at a rate of 15°C / min, and kept for 3 hours; then the temperature was con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com