Method for producing lithium battery anode material doped with multi-elements by secondary depositing method

A technology of secondary deposition and cathode material, applied in battery electrodes, circuits, electrode manufacturing, etc., can solve the problems of material performance deterioration, difficulty in meeting demand, and battery cycle performance deterioration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

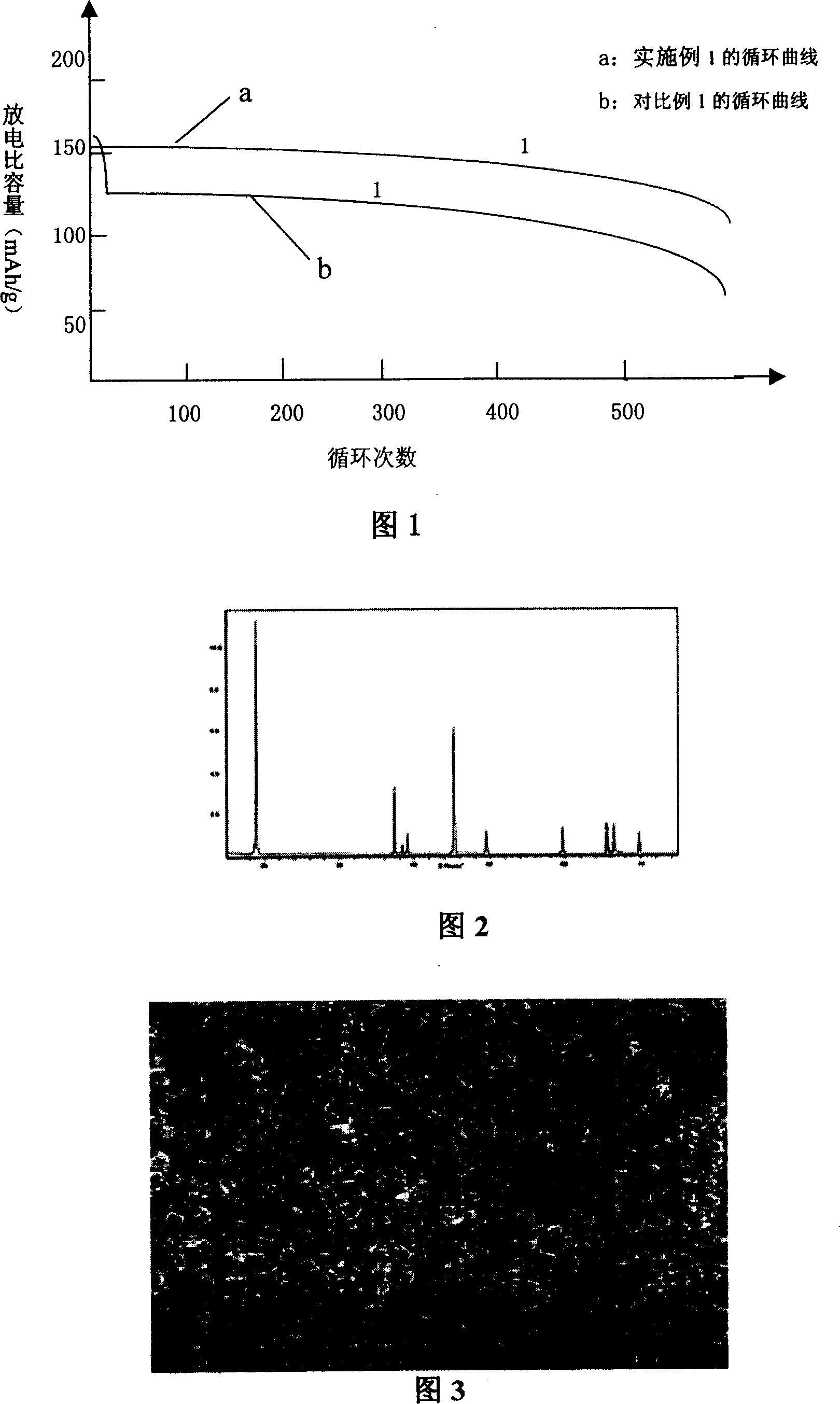

[0032] Embodiment 1: the sulfate salt of Co and Ni, Mn, Mg, Al is made into 2mol / L solution by the ratio of 0.2:032:0.32:0.08:0.08, and the sodium hydroxide containing ammonia 13% is made into 4mol / L L solution is evenly pumped into the reactor with a metering pump, and the pH is controlled to be 10.8. The pH is controlled to 11, and the product is intermediate B, then filtered, washed, and dried; weigh an equimolar amount of lithium hydroxide, wet mix and grind with intermediate B, then dry at 110°C for 4 hours, and sinter at 450°C 20 hours, sintering at 950°C for 24 hours, pulverization, the structural formula of the generated product is: Li(Co 0.2 Ni 0.32 mn 0.32 Al 0.08 Mg 0.08 )O 2 -0.15LiCoO 2 , its X-ray diffraction pattern is shown in Figure 2, and Figure 3 is the product topography image. The product was made into a battery according to the requirements and tested. The results are as follows (see Figure 1): initial discharge capacity (C / 5 4.2-2.8V): 155mAh / g, d...

Embodiment 2

[0033] Embodiment 2: the sulfate salt of Co and Ni, Mn, Mg, Al, Ti presses the ratio of 0.2: 0.28: 0.28: 0.08: 0.08: 0.08, is made into 2mol / L solution, will contain ammoniacal 13% sodium hydroxide Become 4mol / L solution, evenly pump into reaction kettle with metering pump, pH control is 10.8, and its product is intermediate A, then evenly pumps into 15% (relative to the amount of intermediate A) cobalt and Alkaline solution, PH is controlled to 11, then filtered, washed, and dried; Weigh an equimolar amount of lithium hydroxide, wet mix and grind with the intermediate, then dry at 100°C for 4 hours, sinter at 400°C for 16 hours, and sinter at 1000°C Pulverize after 22 hours, the structural formula of generating product is Li(Co 0.2 Ni 0.28 mn 0.28 Al 0.08 Mg 0.08 Ti 0.08 )O 2 -0.15LiCoO 2 , the product was made into a battery according to the requirements, and the test results were as follows: the first discharge capacity (C / 5: 4.2-2.8V): 155mAh / g, the discharge capaci...

Embodiment 3

[0034] Embodiment 3: the sulfate salt of Co and Ni, Mn, Mg, Al presses the ratio of 0.30: 0.28: 0.28: 0.07: 0.07, is made into 2mol / L solution, and the sodium hydroxide that contains ammonia 15% is made into 4mol / L L solution is evenly pumped into the reaction kettle with a metering pump, and the pH control is 11.2, and its product is intermediate A, and then evenly pumped into 28% (relative to the amount of intermediate A) cobalt and alkali solution with a metering pump, Control the pH to 11, then filter, wash, and dry; weigh equimolar lithium hydroxide, wet mix and grind with the intermediate, then dry at 110°C for 4 hours, sinter at 500°C for 18 hours, and sinter at 1100°C for 20 hours. Pulverized, the structural formula of the generated product is Li(Co 0.30 Ni 0.28 mn 0.28 Al 0.07 Mg 0.07 )O 2 -0.28 LiCoO 2 , the product was made into a battery according to the requirements for testing: the first discharge capacity (C / 5, 4.2-2.8V): 159mAh / g, the discharge capacity a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| First discharge capacity | aaaaa | aaaaa |

| Discharge capacity | aaaaa | aaaaa |

| Capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com