Method for producing boron carbide film with electron beam evaporation technique

A technology of electron beam evaporation and boron carbide, which is applied in the direction of vacuum evaporation plating, ion implantation plating, metal material coating technology, etc., can solve the difficulty of meeting the performance requirements of bulletproof materials and wear-resistant materials, and the difficulty of preparing boron carbide films. Difficult to achieve crystal structure and other problems, to achieve the effect of easy control, convenient operation and wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

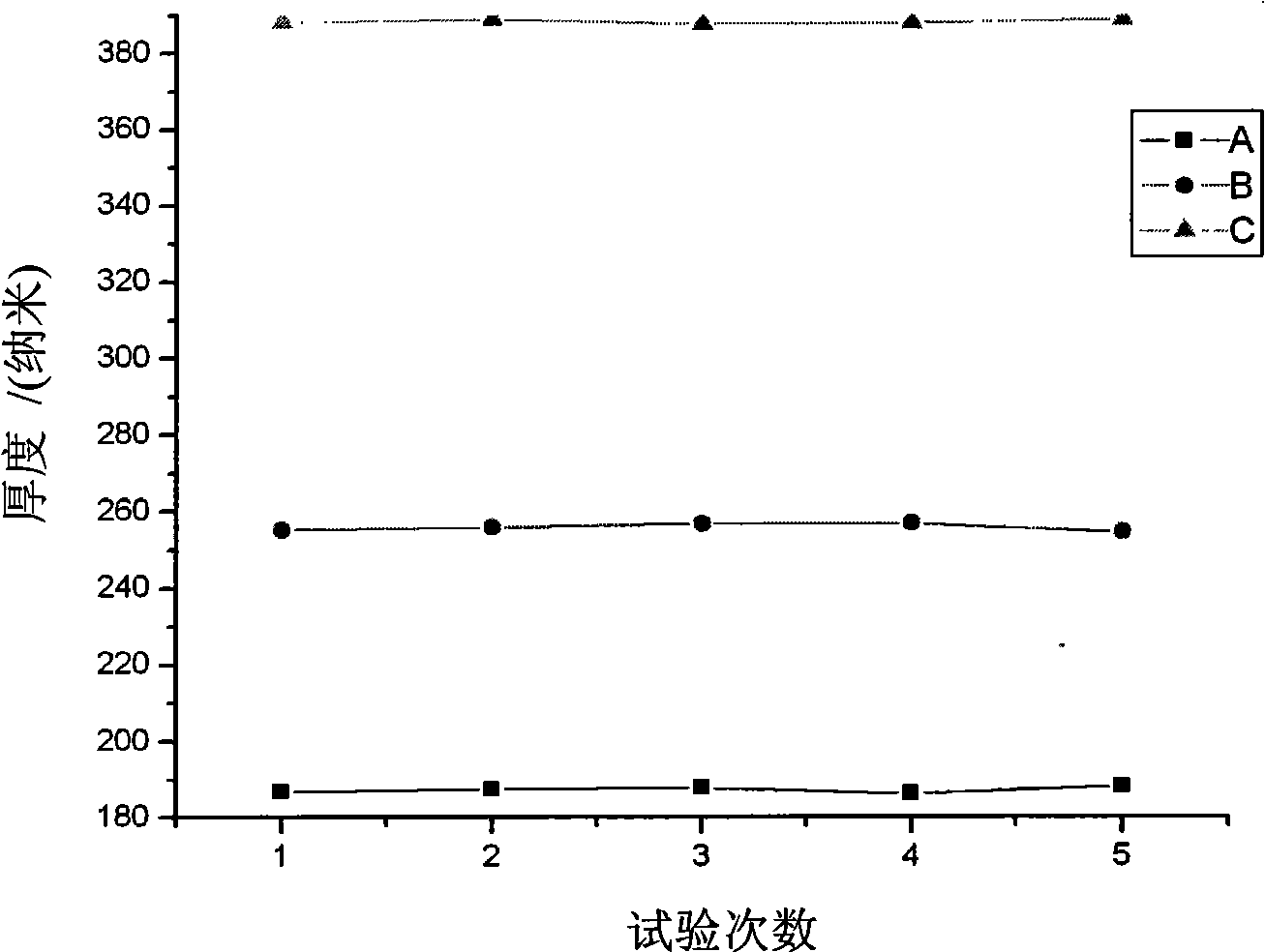

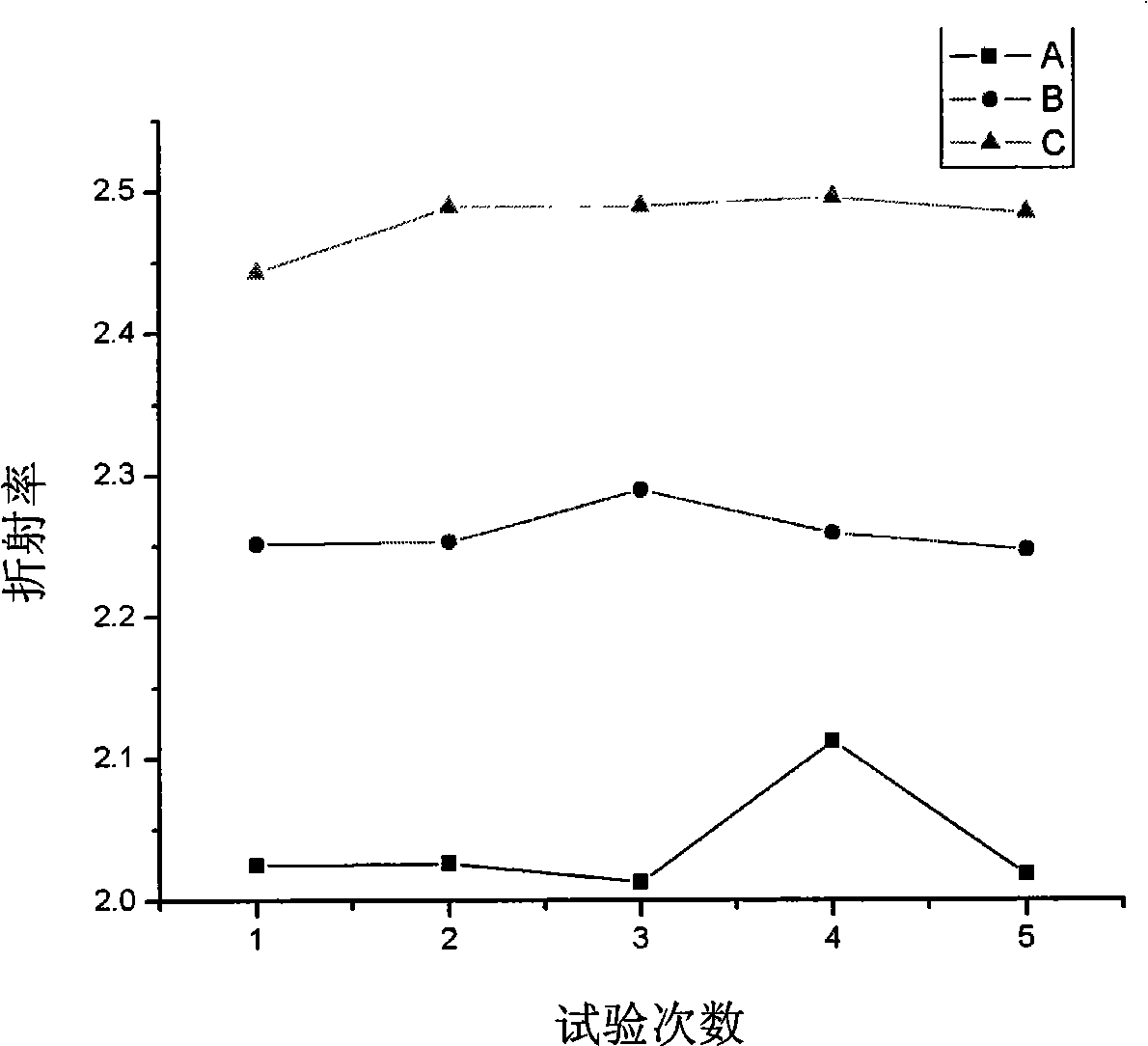

[0025] Under different electron beam currents (electron gun energy), a thin film of boron carbide is deposited on the silicon substrate.

[0026] (1) Preparation of membrane material

[0027] The raw materials are boron powder with a purity of 99.9% and carbon powder with a purity of 99.99%. The molar ratio of carbon powder to boron powder is 1:4; the carbon powder and boron powder are ball milled for 1 hour, mixed evenly, and then placed in a vacuum sintering furnace Sintering, the vacuum degree is 0.01 Pa, the temperature is raised from room temperature to 1900°C at a heating rate of 30°C / min, the holding time is 1 hour, and the temperature is lowered to room temperature at a cooling rate of 20°C / min after holding to obtain boron carbide powder. The boron carbide powder is pressed into a disc (the disc diameter is 20mm, the thickness is 40mm), and the disc is densified at 200MPa isostatic pressing (5 minutes) and then sintered in a vacuum sintering furnace with a vacuum of 0.1Pa...

Embodiment 2

[0033] Change the substrate temperature, and deposit a boron carbide film on the silicon substrate.

[0034] (1) Preparation of membrane material

[0035] The raw materials, process steps and process parameters are the same as in Example 1.

[0036] (2) Coating

[0037] Put the boron carbide film material prepared in step (1) into the crucible of the electron beam evaporation equipment, and put the cleaned and dried silicon substrate F on the heating furnace of the electron beam evaporation equipment, so that the substrate is located 30cm directly above the crucible Place; close the bell jar and vacuum to 1×10 -2 Pa, turn on the bake switch, bake in the vacuum chamber for 10 minutes, heat the silicon substrate, and control the substrate temperature at 25°C (room temperature); continue to vacuum, when the vacuum degree reaches 1×10 -3 At Pa, turn on the power switch and filament switch on the electric control cabinet in order, adjust the filament current at 0.5A, and preheat for 10...

Embodiment 3

[0041] Change the deposition time and deposit a boron carbide film on the silicon substrate.

[0042] (1) Preparation of membrane material

[0043] The raw materials, process steps and process parameters are the same as in Example 1.

[0044] (2) Coating

[0045] Put the boron carbide film material prepared in step (1) into the crucible of the electron beam evaporation equipment, and put the cleaned and dried silicon substrate L on the heating furnace of the electron beam evaporation equipment, so that the substrate is located 30cm above the crucible Place; close the bell jar and vacuum to 1×10 -2 Pa, turn on the bake switch, bake the vacuum chamber for 10 minutes, heat the silicon substrate, and control the substrate temperature at 250°C; continue to vacuum, when the vacuum degree reaches 1×10 -3 At Pa, turn on the power switch and filament switch on the electric control cabinet in order, adjust the beam current to 0.5A, and preheat for 10 minutes; turn on the deflection and focu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

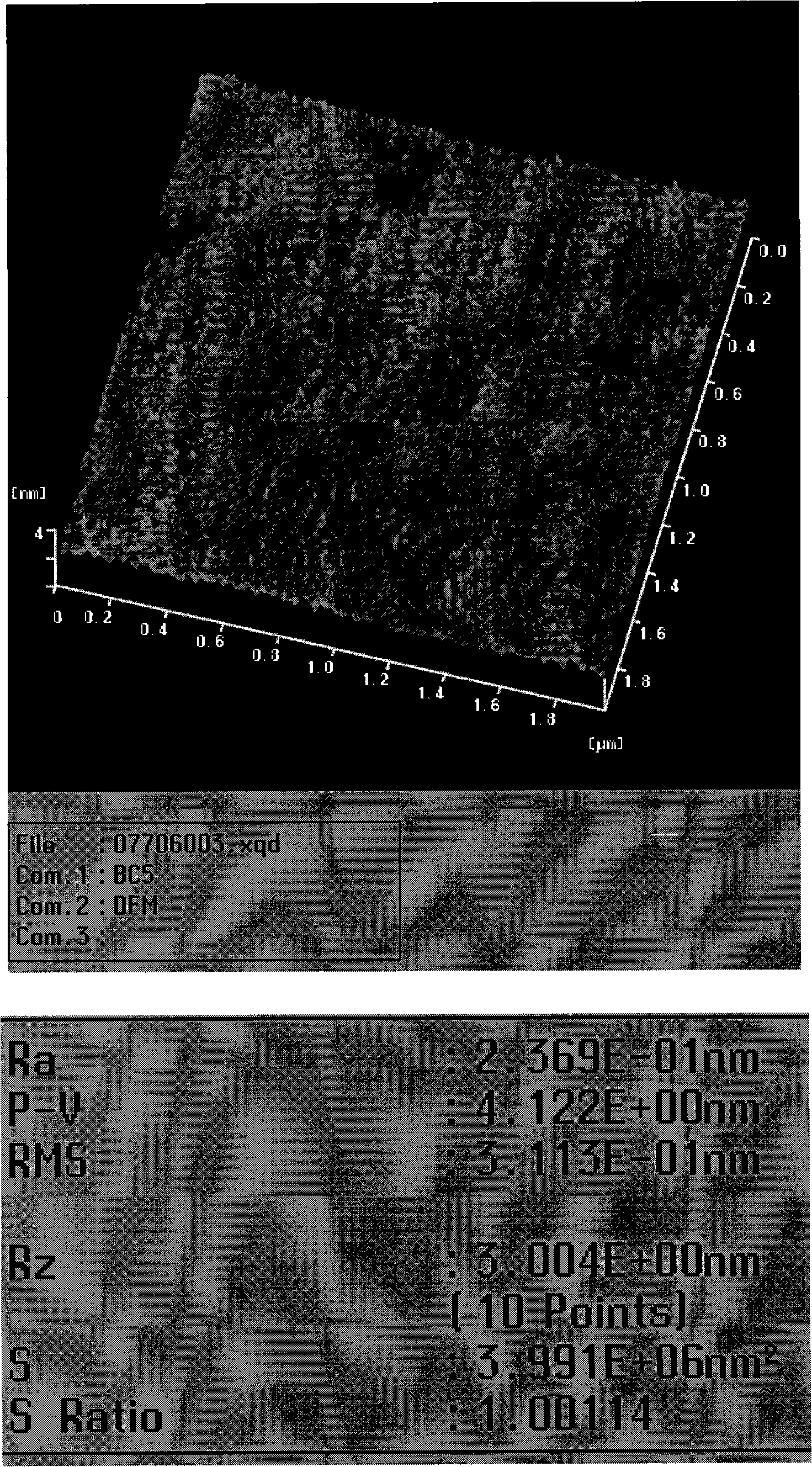

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com