High-entropy ceramic with high-temperature strength and hardness as well as preparation method and application thereof

A high-temperature strength, high-entropy technology, applied in the field of ceramic materials, can solve the problems of difficult solid solution formation of single-phase high-entropy ceramics, different lattice structures, affecting applications, etc., to achieve excellent mechanical properties and oxidation resistance, composition The effect of uniform distribution and improvement of sintering performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

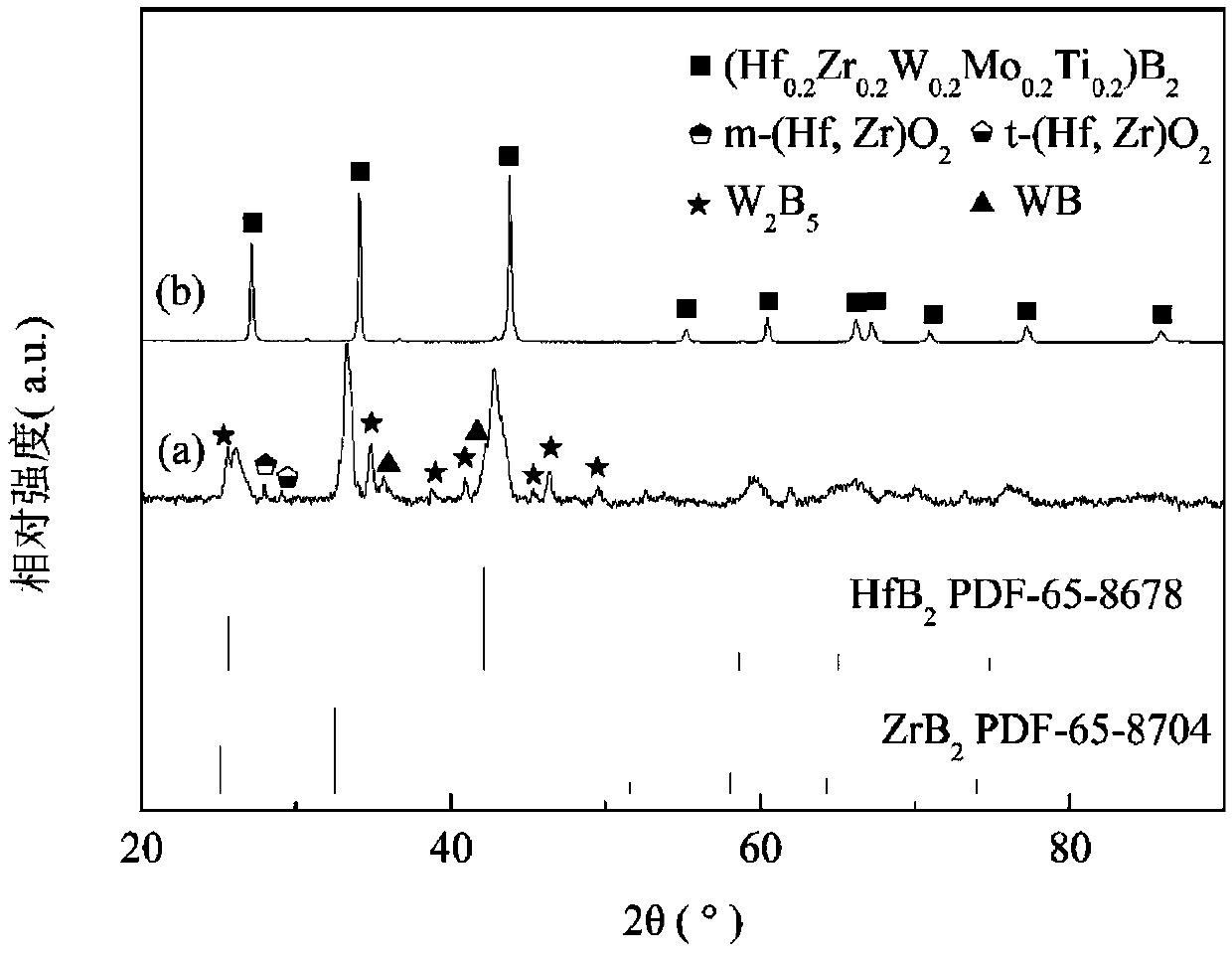

Embodiment 1

[0030] 1. With HfO 2 (powder purity 99.9%, particle size 2μm), ZrO 2 (powder purity 99.9%, particle size 2μm), MoO 3 (powder purity 99.9%, particle size 2μm) and TiO 2 (purity 99% of powder, 2 μm of particle diameter) powder powder is batching and amorphous boron powder (purity 96%, 2 μm of particle diameter) in equal atomic ratio as raw material, for obtaining (Hf 0.25 Zr 0.25 Mo 0.25 Ti 0.25 )B 2 Mix the above oxides with amorphous boron powder.

[0031] 2. With ethanol as solvent, Si 3 N 4 The ball is the ball milling medium, and it is mixed on a roller ball mill for 24 hours, and the mixed powder is obtained after mixing and drying.

[0032] 3. Put the mixed powder into the graphite crucible, raise the temperature to 1100°C at a rate of 10°C / min and keep it for 2 hours, then raise the temperature to 1600°C at a rate of 10°C / min and keep it for 1 hour. The whole sintering process is Vacuum, pressure is 0.1Pa, the powder that obtains grinds and sieves again, obtain...

Embodiment 2

[0036] 1. With HfO 2 (powder purity 99.9%, particle size 2μm), ZrO 2 (powder purity 99.9%, particle size 2μm), WO 3 (powder purity 99.9%, particle size 2μm), MoO 3 (powder purity 99.9%, particle size 2μm) and TiO 2 (purity 99% of powder, 2 μm of particle diameter) powder powder is batching and amorphous boron powder (purity 96%, 2 μm of particle diameter) in equal atomic ratio as raw material, for obtaining (Hf 0.1 Zr 0.2 W 0.3 Mo 0.2 Ti 0.2 )B 2 Mix the above oxides with amorphous boron powder.

[0037] 2. With ethanol as solvent, Si 3 N 4 The ball is the ball milling medium, and it is mixed on a roller ball mill for 24 hours, and the mixed powder is obtained after mixing and drying.

[0038] 3. Put the mixed powder molded green body into a graphite crucible, raise the temperature to 1100°C at a rate of 10°C / min and keep it for 1 hour, then raise the temperature to 1500°C at a rate of 10°C / min and hold it for 1 hour. The whole sintering process is Vacuum, pressure...

Embodiment 3

[0042] 1. With HfO 2 (powder purity 99.9%, particle size 2μm), ZrO 2 (powder purity 99.9%, particle size 2μm), WO 3 (powder purity 99.9%, particle size 2μm), MoO 3 (powder purity 99.9%, particle size 2μm) and TiO 2 (purity 99% of powder, 2 μm of particle diameter) powder powder is batching and amorphous boron powder (purity 96%, 2 μm of particle diameter) in equal atomic ratio as raw material, for obtaining (Hf 0.2 Zr 0.3 W 0.1 Mo 0.2 Ti 0.2 )B 2 Mix the above oxides with amorphous boron powder.

[0043] 2. With ethanol as solvent, Si 3 N 4 The ball is the ball milling medium, and it is mixed on a roller ball mill for 24 hours, and the mixed powder is obtained after mixing and drying.

[0044] 3. Put the mixed powder into the graphite crucible, raise the temperature to 1000°C at a rate of 10°C / min and keep it for 1 hour, then raise the temperature to 1550°C at a rate of 10°C / min and hold it for 1 hour. The whole sintering process is Vacuum, pressure is 0.1Pa, the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Fracture toughness | aaaaa | aaaaa |

| Bending strength at room temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com