Method for preparing multicore C doped with MgB2 superconductive material by in situ method

A superconducting wire, in-situ technology, applied in the usage of superconducting elements, superconducting devices, superconducting/high-conducting conductors, etc. Problems such as micro-cracks are generated, and the effects of reasonable preparation design, good chemical inertness, and increased critical current density are achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

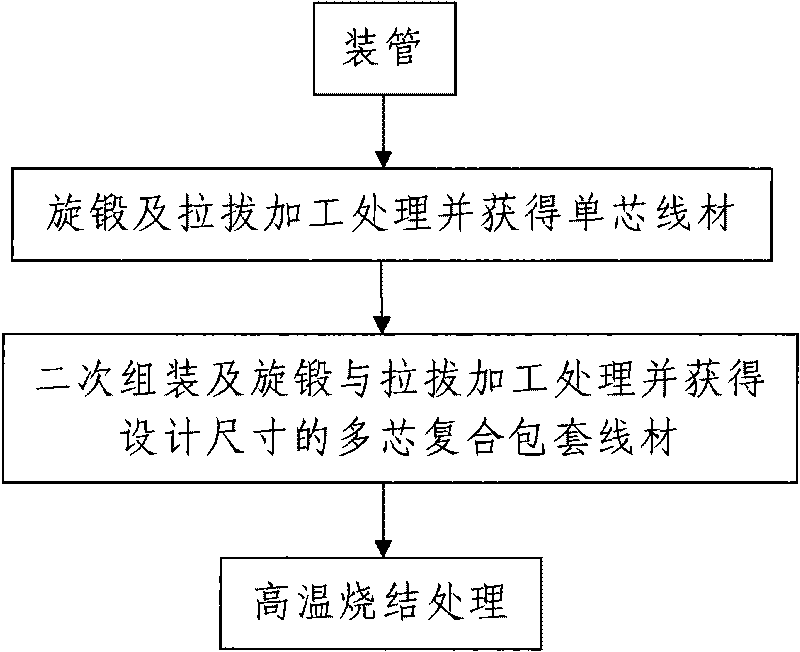

[0043] combine figure 2 , in this example, the multi-core C-doped MgB was prepared by in-situ method 2 When superconducting wire rods, the following steps are included:

[0044] Step 1, tube loading: First, fully mix dry magnesium powder, amorphous boron powder and amorphous carbon powder or nano-carbon powder according to the atomic number ratio of 1:1.95:0.05 to obtain the mixture; after that, The mixed material is put into the pre-acid-washed Nb metal pipe, and an oxygen-free copper pipe is placed on the outside of the Nb metal pipe to obtain a pipe-packing composite.

[0045] When carrying out pickling treatment in this step, carry out pickling to oxygen-free copper pipe one with dilute nitric acid, carry out pickling to Nb metal pipe adopting the mixed acid of nitric acid and hydrofluoric acid to form, all carry out dehydration and drying with alcohol after pickling and the purity of the magnesium powder and the amorphous boron powder is 99%.

[0046] Step 2, swaging ...

Embodiment 2

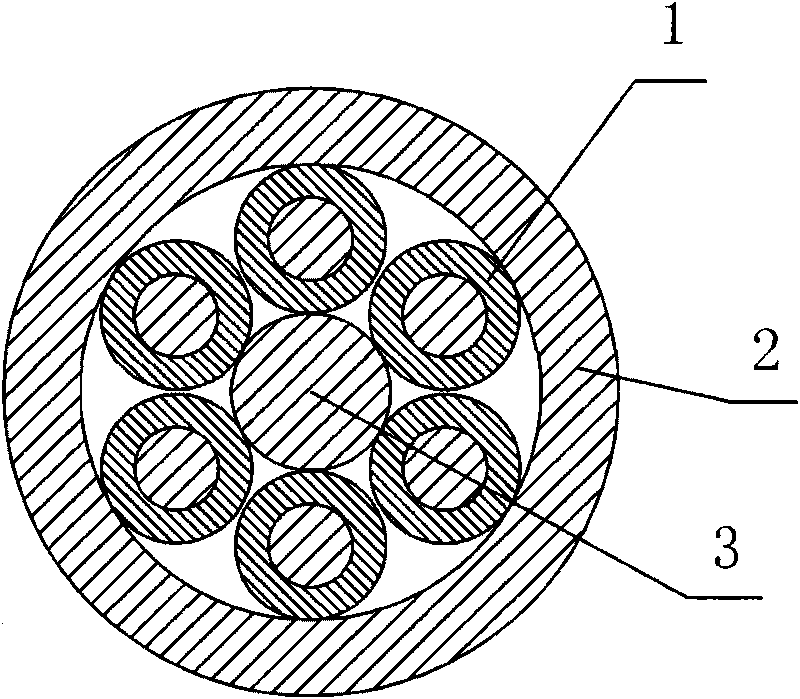

[0052] combine image 3 , in this embodiment, the difference from embodiment 1 is that in step two, a swaging machine and a drawing machine are used to carry out swaging and drawing treatment on the tube-loading complex described in step one successively, and obtain a cross-section of positive six A single-core wire 1 that is square and has a vertical width across sides of Φ3.0 mm. When carrying out high-temperature sintering treatment in step 4, first put the 6-core composite sheathed wire into the tubular annealing furnace, fill it with circulating pure argon, and after 2 hours, put the 6-core composite sheathed wire at a heating rate of 50°C / min Heating, when the temperature rises to 900°C, keep it warm for 1.0h, and finally cool the wire to room temperature at a cooling rate of 45°C / min. In this embodiment, the rest of the process steps, process parameters and preparation process are the same as in Example 1.

Embodiment 3

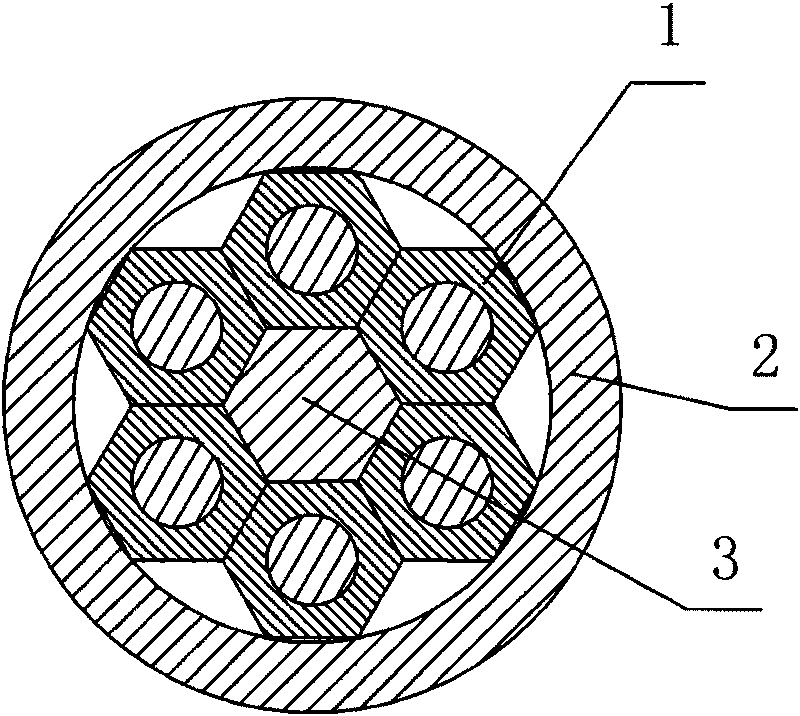

[0054] combine Figure 4 , in this embodiment, the difference from Example 1 is that in step 1, dry magnesium powder, amorphous boron powder and amorphous carbon powder or nano carbon powder are fully mixed according to the ratio of atomic number of 1: 1.90: 0.1 Evenly, the mixture is obtained; in step 301, the cleaned 12 single-core wires 1 are arranged in a circular structure along the circumferential direction and assembled into an oxygen-free copper tube 2, and at the same time inserted inside the circular structure After entering the oxygen-free copper rod 3, a 12-core composite sheathed tube is obtained; correspondingly, after the secondary swaging and drawing processing in step 302, a 12-core composite sheathed wire with a diameter of Φ1.0mm is obtained; step 4 When carrying out high-temperature sintering treatment in the middle, first put the 12-core composite sheathed wire into the tubular annealing furnace, fill it with circulating pure argon, and heat the 12-core co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com