Coating coating on blade substrate and preparation method thereof

A blade and substrate technology, which is applied in the field of coating and preparation on the blade substrate, can solve the problems of easy formation of holes and crystals, reduce tool life, chipping, etc., achieve fine grain size, high blade toughness, Excellent hardness and wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] The surface of the cemented carbide cutting blade is coated with a medium temperature layer and an alumina layer, specifically including: four sets of alternately deposited TiN layers and TiCN layers, the thickness of the TiN layer and TiCN layer are both 0.5-1.0 μm; five sets of alternately deposited layers TiCNO and TiN layers, the thickness of both TiCNO and TiN layers is 0.5-1.0 μm; a layer of AlTiCNO layer, the thickness is 0.1-1.5 μm; a layer of alumina nucleation layer, the thickness is 0.1-0.8 μm; a layer of alumina coating layer with a thickness of 3-10 μm. The detailed process for preparing the above coatings is shown in the table below.

[0047] Table 1 embodiment 1 detailed process parameter

[0048]

[0049]

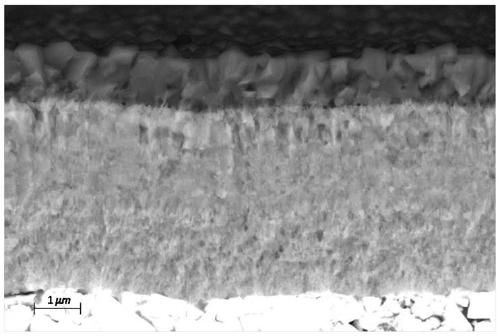

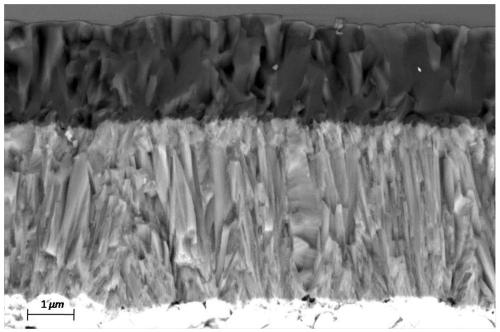

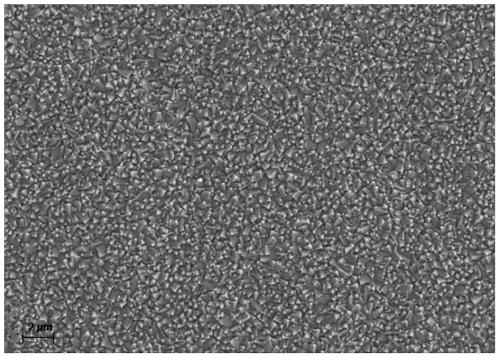

[0050] figure 1 , 3 , 5 and 7 are electron microscope results of the coating of this embodiment. Depend on figure 1 It can be seen that the aluminum oxide coating is composed of columnar grains; the aspect ratio of the columnar grains is 1 ...

Embodiment 2

[0052] The surface of the cemented carbide cutting blade is coated with a medium temperature layer and an alumina layer, specifically including: five sets of alternately deposited TiN layers and TiCN layers, the thickness of the TiN layer and TiCN layer are both 0.5-1.0 μm; five sets of alternately deposited layers TiCNO and TiN layers, the thickness of both TiCNO and TiN layers is 0.5-1.0 μm; a layer of AlTiCNO layer, the thickness is 0.1-1.5 μm; a layer of alumina nucleation layer, the thickness is 0.1-0.8 μm; a layer of alumina coating layer with a thickness of 3-10 μm. The detailed process for preparing the above coatings is shown in the table below.

[0053] Table 1 embodiment 2 detailed process parameters

[0054]

Embodiment 3

[0056] The surface of the cemented carbide cutting blade is coated with a medium temperature layer and an alumina layer, specifically including: four sets of alternately deposited TiN layers and TiCN layers, the thickness of the TiN layer and TiCN layer are both 0.5-1.0 μm; six sets of alternately deposited layers TiCNO and TiN layers, the thickness of both TiCNO and TiN layers is 0.5-1.0 μm; a layer of AlTiCNO layer, the thickness is 0.1-1.5 μm; a layer of alumina nucleation layer, the thickness is 0.1-0.8 μm; a layer of alumina coating layer with a thickness of 3-10 μm. The detailed process for preparing the above coatings is shown in the table below.

[0057] Table 1 embodiment 3 detailed process parameters

[0058]

[0059]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com