Impermeable concrete

A technology of impermeable concrete and bentonite, which is applied in the field of construction and civil engineering, can solve the problems of unsatisfactory impermeability, etc., and achieve the effect of ensuring antifreeze and antifreeze performance, high content, and improving impermeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

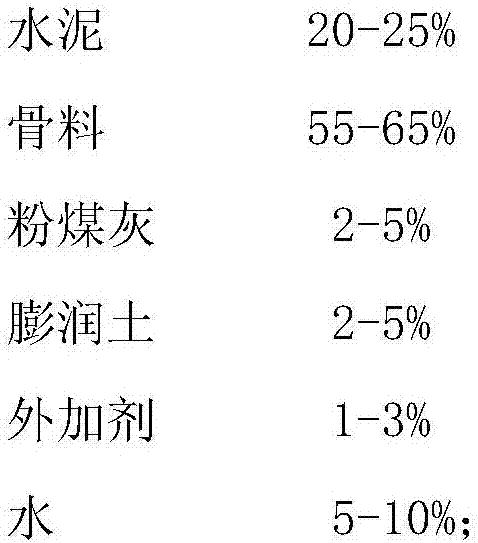

[0026] A kind of anti-seepage concrete, is made up of the following components by weight percentage:

[0027]

[0028]

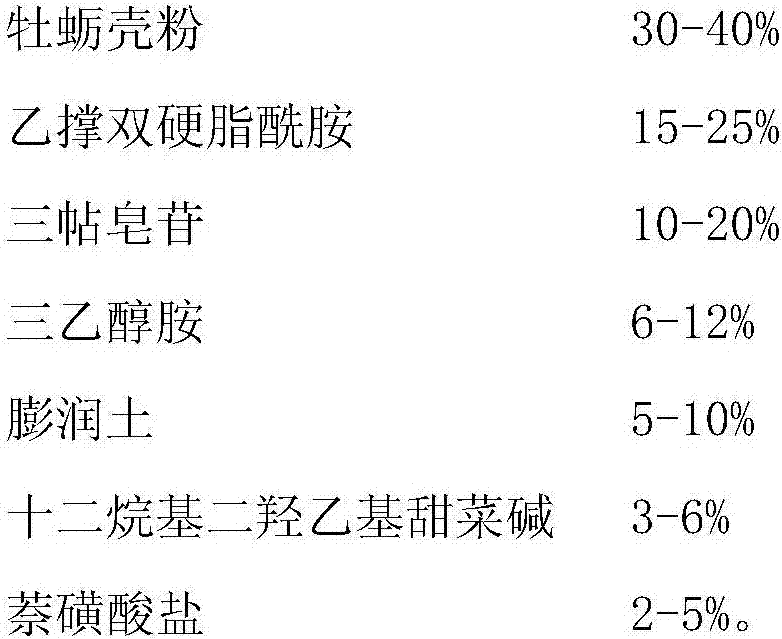

[0029] Wherein, the admixture is composed of the following components in mass percentage:

[0030]

[0031] Wherein, the particle size of the oyster shell powder is 600 mesh; the aggregate includes river sand and stones, and the stones include pebbles, limestone, etc., and the particle size of the stones is below 2cm;

[0032] The preparation method is:

[0033] Prepare the admixture first: weigh the components of the admixture in the mass ratio, then mix them evenly, add 10% water of the total mass of the admixture, the water contains about 3% organic acid by mass, and then heat to 95 ℃, after reacting for 30 minutes, dry and grind to get the product;

[0034] Then, "concrete A" was prepared according to the preparation method of ordinary concrete.

Embodiment 2

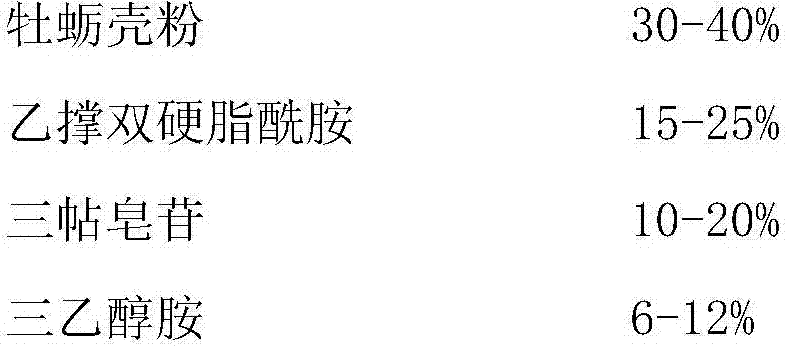

[0036] A kind of anti-seepage concrete, is made up of the following components by weight percentage:

[0037]

[0038] Wherein, the admixture is composed of the following components in mass percentage:

[0039]

[0040]

[0041] Wherein, the particle size of the oyster shell powder is 600 mesh; the aggregate includes river sand and stones, and the stones include pebbles, limestone, etc., and the particle size of the stones is below 2cm;

[0042] The preparation method is:

[0043] Prepare the admixture first: weigh the components of the admixture in the mass ratio, then mix them evenly, add 10% water of the total mass of the admixture, the water contains about 5% organic acid by mass, and then heat to 85 ℃, after reacting for 30 minutes, dry and grind to get the product;

[0044] Then prepare "concrete B" according to the preparation method of ordinary concrete

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com