Technology for manufacturing low-temperature mold pressing tee through X80 steel plate

A low-temperature mold and steel plate technology, applied in the direction of manufacturing tools, furnace types, furnaces, etc., can solve the problems of shortening the service life of tee pipe fittings, inhomogeneous pipe fitting structure, and sensitive thermal processing temperature, etc., and achieve low welding crack sensitivity coefficient , high strength and improved homogeneity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

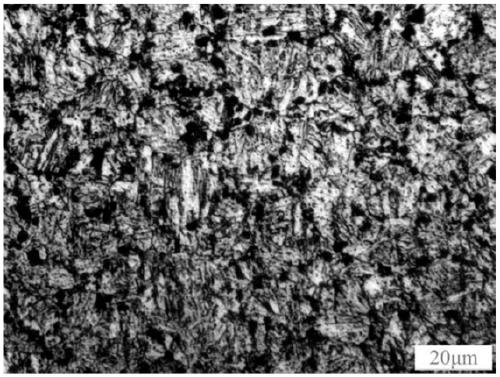

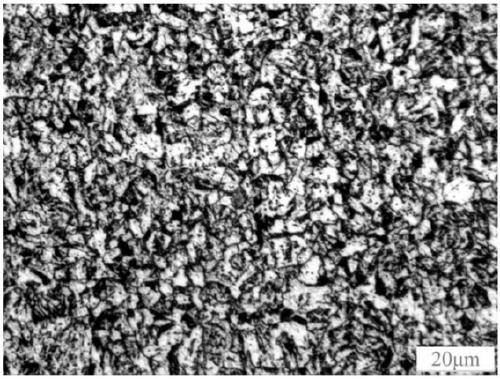

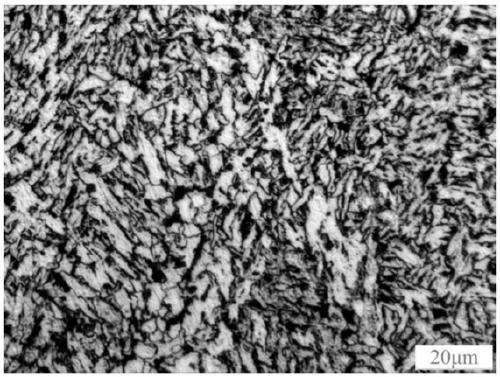

Image

Examples

Embodiment

[0027] A kind of technology that utilizes X80 steel plate to manufacture low-temperature molding tee, comprises the following steps:

[0028] The X80 steel plate with a thickness of 58mm is selected as the raw material, and the percentages of each element of the X80 steel are as follows: C0.06%, Mn 1.5%, Si 0.23%, Cr 0.15%, Mo 0.39%, V0.037%, Ni 0.77%, Nb 0.045%, Cu 0.14%, the balance is Fe and unavoidable impurities 1.5 grade, grain size is 10 grade, CE Pcm 0.2%;

[0029] Cut the raw material into rectangular blanks;

[0030] Roll the rectangular blank into a cylindrical blank, and weld the longitudinal weld of the cylindrical blank. During the welding process, the preheating temperature is 200°C, the interlayer temperature is 150°C, and the welding current is 150A, and the welding speed is 20cm / min, and the heat input is 18KJ / cm, and the type of electrode used is E11016-G / L-80SN;

[0031] Perform the first tempering treatment on the welded cylindrical blank, the temperat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com