Graphite-phase carbon nitride composite photocatalyst and preparation method thereof

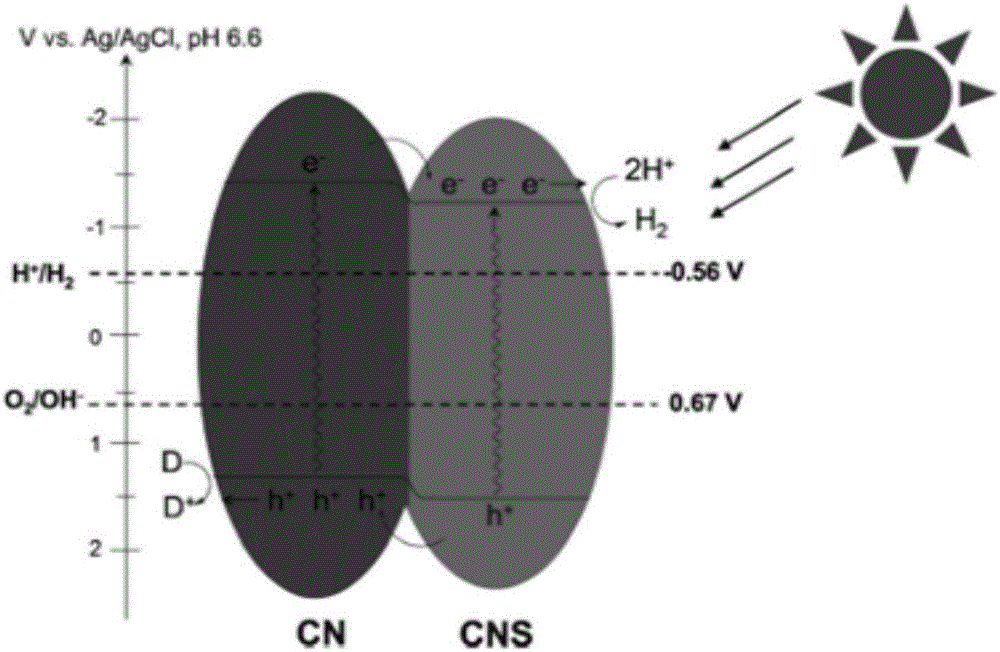

A technology of graphite phase carbon nitride and photocatalyst, which is applied in the direction of physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc. Carbon nitride and other semiconductors are evenly mixed to achieve the effect of improving separation efficiency, improving photocatalytic performance, and improving mixing uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

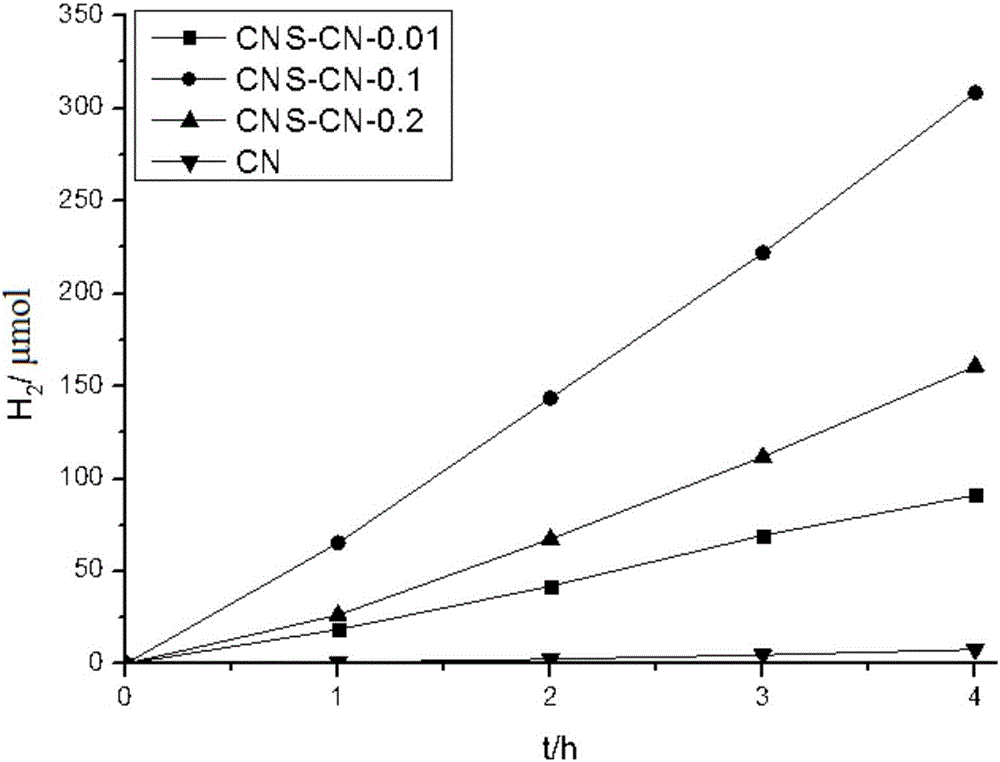

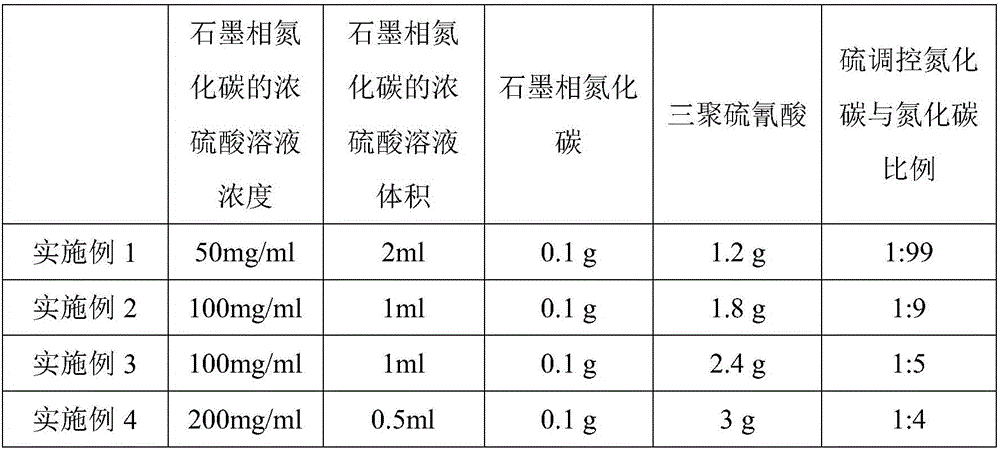

[0022] Concentrated sulfuric acid dissolves graphite phase carbon nitride: Take 0.5g graphite phase carbon nitride and add it to a 25ml round bottom flask, then add 10ml of concentrated sulfuric acid, stir and heat in an oil bath to 100°C, heat for 1h, and wait for graphite phase carbon nitride All dissolved and cooled to room temperature to obtain a concentrated sulfuric acid solution of graphite carbon nitride with a concentration of 50 mg / ml.

[0023] Graphite phase carbon nitride is homogeneously mixed: take 2ml of the concentrated sulfuric acid solution of graphite phase carbon nitride and add 1.2g of thiocyanuric acid to it, so that the sulfur in the finally obtained compound can regulate the graphite phase carbon nitride and graphite phase nitrogen The carbonization ratio is 1:99, the obtained mixture is stirred into a paste with a glass rod, then 30ml of secondary water is added, stirred with an electromagnetic stirrer for 30min, left to stand for 1h, then suction filte...

Embodiment 2

[0026] Concentrated sulfuric acid dissolves graphite phase carbon nitride: Take 1g of graphite phase carbon nitride and add it to a 25ml round bottom flask, then add 10ml of concentrated sulfuric acid, stir in an oil bath and heat to 60°C, heat for 1h, until the graphite phase carbon nitride is completely Dissolve and cool to room temperature to obtain a concentrated sulfuric acid solution of graphite carbon nitride with a concentration of 100 mg / ml.

[0027] Graphite phase carbon nitride is homogeneously mixed: get the concentrated sulfuric acid solution of 1ml graphite phase carbon nitride and add 1.8g thiocyanuric acid to it, so that sulfur regulates the ratio of carbon nitride and carbon nitride in the compound obtained finally to be 1:9, the obtained mixture was stirred into a paste with a glass rod, then 30ml of secondary water was added, stirred with an electromagnetic stirrer for 30min, allowed to stand for 1h, then filtered using a Buchner funnel, and then the sample w...

Embodiment 3

[0030] Concentrated sulfuric acid dissolves graphite phase carbon nitride: Take 1g of graphite phase carbon nitride and add it to a 25ml round bottom flask, then add 10ml of concentrated sulfuric acid, stir and heat in an oil bath to 150°C, heat for 1h, until the graphite phase carbon nitride is completely Dissolve and cool to room temperature to obtain a concentrated sulfuric acid solution of graphite carbon nitride with a concentration of 100 mg / ml.

[0031] Graphite phase carbon nitride is homogeneously mixed: get the concentrated sulfuric acid solution of 1ml graphite phase carbon nitride and add 2.4g thiocyanuric acid to it, so that the ratio of sulfur in the compound obtained finally is adjusted carbon nitride and carbon nitride to be 1:5, stir the obtained mixture into a paste with a glass rod, then add 30ml of secondary water, stir with an electromagnetic stirrer for 30min, let it stand for 1h, then use a Buchner funnel for suction filtration, and then dry the sample. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com