Intumescent flame retardant containing phosphorus, nitrogen and sulfur and preparation method of intumescent flame retardant

An intumescent flame retardant, nitrogen-sulfur technology, applied in the field of halogen-free flame retardant, can solve the problems of low flame retardant efficiency, single flame retardant element, complex preparation process, etc., to achieve improved flame retardant performance, good water resistance, and preparation The effect of simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Put 1.77 g of thiocyanuric acid, 3.04 g of triethylamine and 50 ml of tetrahydrofuran in a three-necked flask. Under the conditions of ice bath and nitrogen, add 7.10 g of diphenylphosphinyl chloride dropwise. The reaction was continued for 1 hour under the bath and nitrogen conditions, then the temperature was raised to 60°C, and the reaction was conducted under nitrogen conditions for 6 hours. Finally, the resulting product was filtered to remove the precipitation and the solvent was removed. The obtained light yellow solid powder is the phosphorus-containing nitrogen-sulfur expansion of the present invention Type flame retardant.

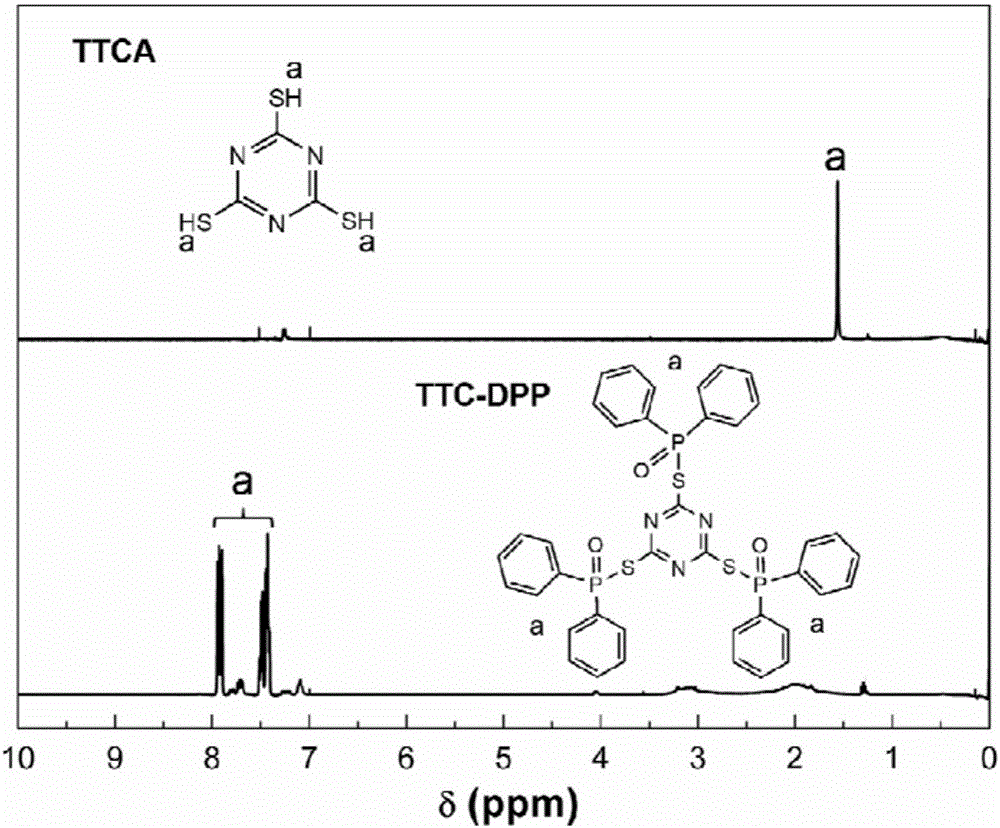

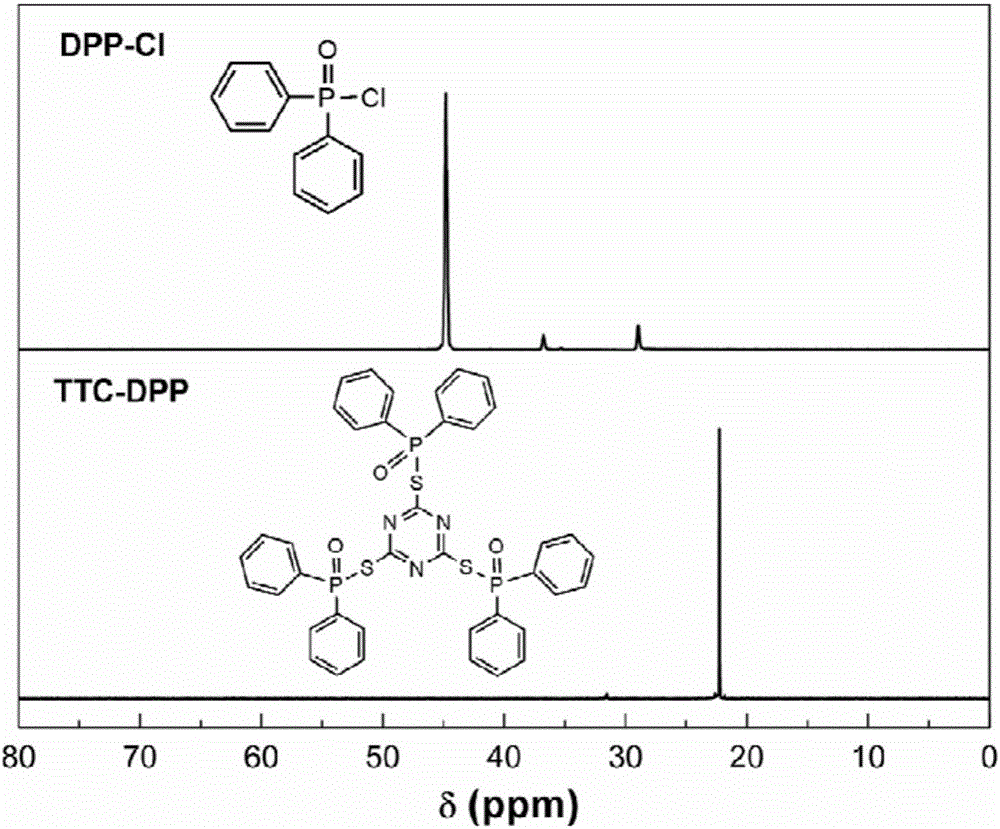

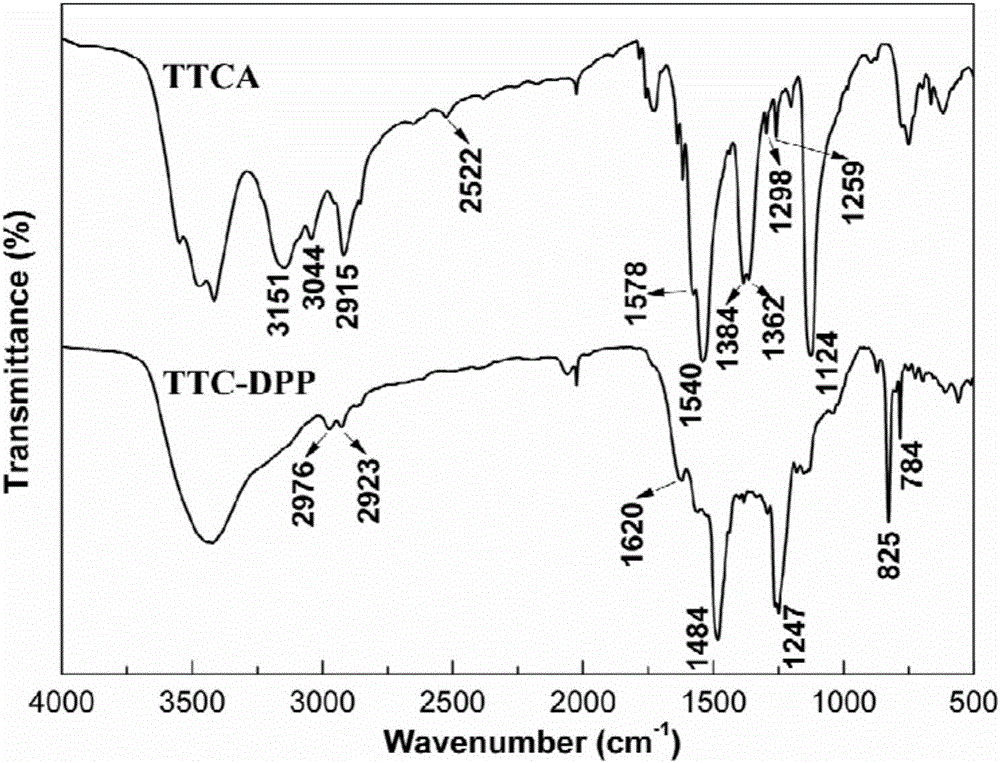

[0022] Attached figure 1 The proton nuclear magnetic resonance spectrum ( 1 HNMR, CDCl 3 , Δ, ppm, TMS), it can be seen that TTCA has a single peak at the chemical shift value of 1.5 ppm, which is attributed to the H of the sulfhydryl (-SH) in TTCA, while the single peak in the hydrogen spectrum of TTC-DPP weakens even The disappearance indic...

Embodiment 2

[0027] Put 1.77 g of thiocyanuric acid, 2.37 g of pyridine and 50 ml of N,N-dimethylformamide in a three-necked flask, and add 7.10 g of diphenylphosphinyl chloride dropwise under ice bath and nitrogen conditions. After the dripping is completed, the reaction is continued for 2 hours under ice bath and nitrogen conditions, then the temperature is raised to 50°C, and the reaction is carried out under nitrogen conditions for 8 hours. Finally, the obtained product is filtered to remove the precipitate and the solvent is removed. The obtained light yellow solid powder is the present invention. Intumescent flame retardant containing phosphorus, nitrogen and sulfur.

Embodiment 3

[0029] Put 1.77 g of thiocyanuric acid, 2.97 g of pyridine and 50 ml of N,N-dimethylformamide in a three-necked flask, add 4.22 g of diethylphosphinyl chloride dropwise under ice bath and nitrogen conditions, After the addition is completed, the reaction is continued for 3 hours under ice bath and nitrogen conditions, then the temperature is raised to 40°C, and the reaction is carried out under nitrogen conditions for 9 hours. Finally, the resulting product is filtered to remove the precipitate and the solvent is removed. The obtained light yellow solid powder is the invention Intumescent flame retardant containing phosphorus, nitrogen and sulfur.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com