Method for preparing three-dimensional porous nitrogen-sulfur doped carbon nanosheet

A carbon nanosheet, three-dimensional porous technology, applied in nanocarbon, nanotechnology, nanotechnology and other directions, to achieve the effects of large-scale preparation, low cost, and easy experimental operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] (1) Dissolve 30mg of graphene oxide in 30ml of deionized water, ultrasonically disperse, then add 0.063g of melamine, stir evenly, and record it as liquid A.

[0017] (2) Dissolve 0.177g of thiocyanuric acid in 30ml of ethanol, stir evenly, and record it as solution B.

[0018] (3) Under the condition of magnetic stirring, slowly drop liquid B into liquid A, and then heat the obtained solution in a water bath at 80°C for 10 h with continuous stirring.

[0019] (4) Freeze-dry the sample, then raise the temperature to 350°C at a heating rate of 10°C / min in a vacuum environment and keep it warm for 2 hours, then raise the temperature to 700°C at the same heating rate and keep it warm for 2 hours. Perform cooling process.

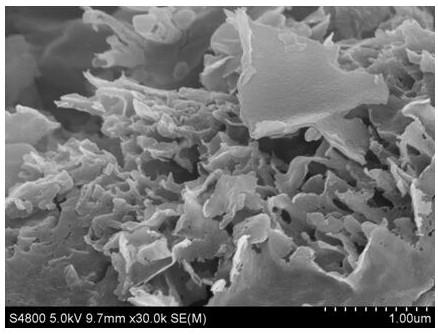

[0020] Refer to attached figure 1 , figure 1 SEM photographs of samples prepared for this example. The S-4800 scanning electron microscope (SEM) of Japan Electronics Co., Ltd. was used to observe the morphology, and the porous three-dimensional nanos...

Embodiment 2

[0022] (1) Dissolve 60mg of graphene oxide in 30ml of deionized water, ultrasonically disperse, then add 0.063g of melamine, stir evenly, and record it as liquid A.

[0023] (2) Dissolve 0.354g of thiocyanuric acid in 15ml of nitrogen-methylpyrrolidone, stir evenly, and record it as liquid B.

[0024] (3) Under the condition of magnetic stirring, slowly drop liquid B into liquid A, and then heat the obtained solution in a water bath at 100°C for 2 hours with continuous stirring.

[0025] (4) Freeze-dry the sample, then raise the temperature to 500°C at a heating rate of 20°C / min in a vacuum environment and keep it warm for 2 hours, then raise the temperature to 800°C at the same heating rate and keep it warm for 1 hour. Perform cooling process.

Embodiment 3

[0027] (1) Dissolve 100mg of graphene oxide in 25ml of deionized water, ultrasonically disperse, then add 0.126g of melamine, stir well, and record it as liquid A.

[0028] (2) Dissolve 0.177g of thiocyanuric acid in 20ml of nitrogen-methylpyrrolidone, stir evenly, and record it as liquid B.

[0029] (3) Under the condition of magnetic stirring, slowly drop liquid B into liquid A, and then heat the obtained solution in a water bath at 120°C for 1 hour with continuous stirring.

[0030] (4) Freeze-dry the sample, then raise the temperature to 400°C at a heating rate of 20°C / min in a vacuum environment and keep it warm for 3 hours, then raise the temperature to 900°C at the same heating rate and keep it warm for 0.5h. Protect the cooling process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com