Sulfur-doped g-C3N4/C-dot porous composite photocatalyst and preparing method and application thereof

A C3N4, c-dot technology, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., to achieve the effect of increased specific surface area, low cost, and increased specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

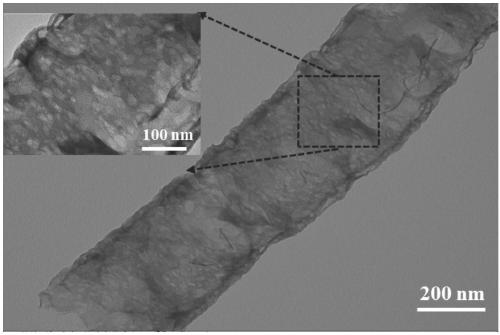

[0045] A sulfur-doped g-C 3 N 4 The preparation method of / C-dot porous composite photocatalyst comprises steps as follows:

[0046] (1) By stirring and mixing melamine and thiocyanuric acid, sulfur-doped C 3 N 4 (S-C 3 N 4 )Precursor:

[0047] Dissolve melamine and thiocyanic acid in equal molar ratios in hot water at 90°C and mix evenly for 10 minutes, then mix the two and transfer them to a polytetrafluoroethylene reactor for hydrothermal reaction. Specific conditions: put the reaction kettle in an oven at 100°C for 4 hours, take it out after cooling, wash it with deionized water several times, and then put it in an oven to dry to obtain S-C 3 N 4 precursors.

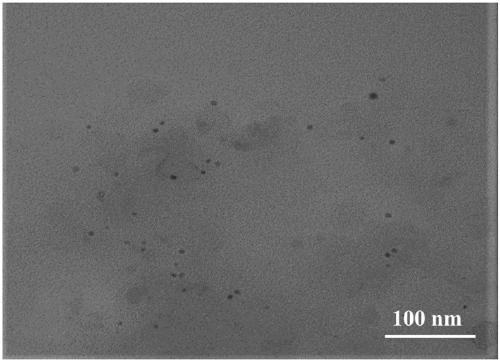

[0048] (2) carbonization of carbon-containing organic matter by alkali-assisted ultrasonic method to obtain C-dot nanoparticles:

[0049] Dissolve 9g of glucose in 50mL of deionized water, stir until it forms a clear solution, then add 0.8g of sodium hydroxide and stir to mix evenly. The ultrasonic time is ...

Embodiment 2

[0056] A sulfur-doped g-C 3 N 4 The preparation method of / C-dot porous composite photocatalyst comprises steps as follows:

[0057] (1) Sulfur-doped g-C was prepared by stirring and mixing melamine and thiocyanuric acid 3 N 4 (S-C 3 N 4 )Precursor:

[0058] Dissolve melamine and thiocyanic acid in equal molar ratios in hot water at 90°C and mix evenly for 10 minutes, then mix the two and transfer them to a polytetrafluoroethylene reactor for hydrothermal reaction. Specific conditions: put the reaction kettle in an oven at 100°C for 4 hours, take it out after cooling, wash it with deionized water several times, and then put it in an oven to dry to obtain S-C 3 N 4 precursors.

[0059] (2) C-dot nanoparticles were obtained by carbonizing carbon-containing organic matter by alkali-assisted ultrasonic method: Dissolve 9 g of glucose in 50 mL of deionized water, stir until it forms a clear solution, then add 0.8 g of sodium hydroxide and stir to mix evenly , and the obtai...

Embodiment 3

[0064] A sulfur-doped g-C 3 N 4 The preparation method of / C-dot porous composite photocatalyst comprises steps as follows:

[0065] (1) Sulfur-doped g-C was prepared by stirring and mixing melamine and thiocyanuric acid 3 N 4 (S-C 3 N 4 )Precursor:

[0066] Dissolve melamine and thiocyanic acid in equal molar ratios in hot water at 90°C and mix evenly for 10 minutes, then mix the two and transfer them to a polytetrafluoroethylene reactor for hydrothermal reaction. Specific conditions: put the reaction kettle in an oven at 100°C for 4 hours, take it out after cooling, wash it with deionized water several times, and then put it in an oven to dry to obtain S-C 3 N 4 precursors.

[0067] (2) C-dot nanoparticles were obtained by carbonizing carbon-containing organic matter by alkali-assisted ultrasonic method: Dissolve 9 g of glucose in 50 mL of deionized water, stir until it forms a clear solution, then add 0.8 g of sodium hydroxide and stir to mix evenly , and the obtai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com