Preparation method of CuS/ZnS/g-C3N4 ternary composite photocatalyst

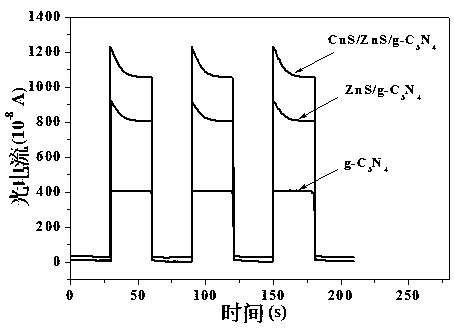

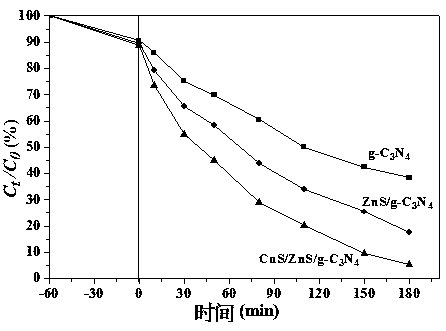

A ternary composite and photocatalyst technology, which is applied in the direction of catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc. It can solve problems such as difficult operation, complex preparation process of multiple composite photocatalysts, and harsh reaction conditions. , to achieve the effects of no pollution to the environment, high separation efficiency of photogenerated electrons and holes, and easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

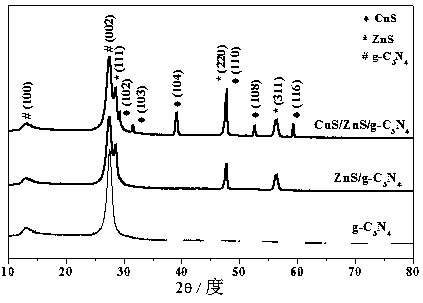

[0017] A CuS / ZnS / g-C 3 N 4 Preparation method of ternary composite photocatalyst to directly obtain CuS / ZnS / g-C by one-step calcination method 3 N 4 Ternary heterostructure, the specific steps are as follows,

[0018] In the first step, a certain amount of CuCl 2 2H 2 O, ZnCl 2 Mix with thiocyanuric acid to form a precursor mixture; in the second step, grind the mixture evenly and place it in a tube furnace for calcination. The resulting product is washed with distilled water and absolute ethanol and dried to obtain CuS / ZnS / g-C 3 N 4 Ternary composite photocatalyst.

[0019] CuCl 2 2H 2 O, ZnCl 2 The mass ratio to thiocyanic acid is 1~5:1~8:5~20.

[0020] The calcination time is 2~6h, and the calcination temperature is 350~600°C.

[0021] Calcination was performed under nitrogen atmosphere.

Embodiment 1

[0023] A CuS / ZnS / g-C 3 N 4 The preparation method of ternary composite photocatalyst, concrete steps are as follows:

[0024] 2g CuCl 2 2H 2 O, 2g ZnCl 2 Mix it with 6g of thiocyanic acid to form a precursor mixture, grind the mixture evenly, place it in a tube furnace, and calcinate it at 400°C for 3h in a nitrogen atmosphere, wash the obtained product with distilled water and absolute ethanol, and then dry it. That is, CuS / ZnS / g-C is obtained 3 N 4 Ternary composite photocatalyst.

Embodiment 2

[0026] A CuS / ZnS / g-C 3 N 4 The preparation method of ternary composite photocatalyst, concrete steps are as follows:

[0027] 2g CuCl 2 2H 2 O, 2.5g ZnCl 2 Mix it with 8g of thiocyanic acid to form a precursor mixture, grind the mixture evenly, place it in a tube furnace, and calcinate it at 450°C for 3h in a nitrogen atmosphere, wash the obtained product with distilled water and absolute ethanol, and then dry it. That is, CuS / ZnS / g-C is obtained 3 N 4 Ternary composite photocatalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com