Absorption type ALC (Autoclaved Lightweight Concrete) wallboard pipeline integrated production method

A production method and absorption technology, which is applied in the field of integrated production of absorption ALC plate pipelines, can solve the problems of complex hole punching technology, low manufacturing cost, high temperature resistance or high cost of metal pipes, and achieve low cost and simple production and processing , to overcome the effect of high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below with reference to the accompanying drawings and examples. It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other. For the convenience of description, if the words "up", "down", "left" and "right" appear in the following, it only means that the directions of up, down, left and right are consistent with the drawings themselves, and do not limit the structure.

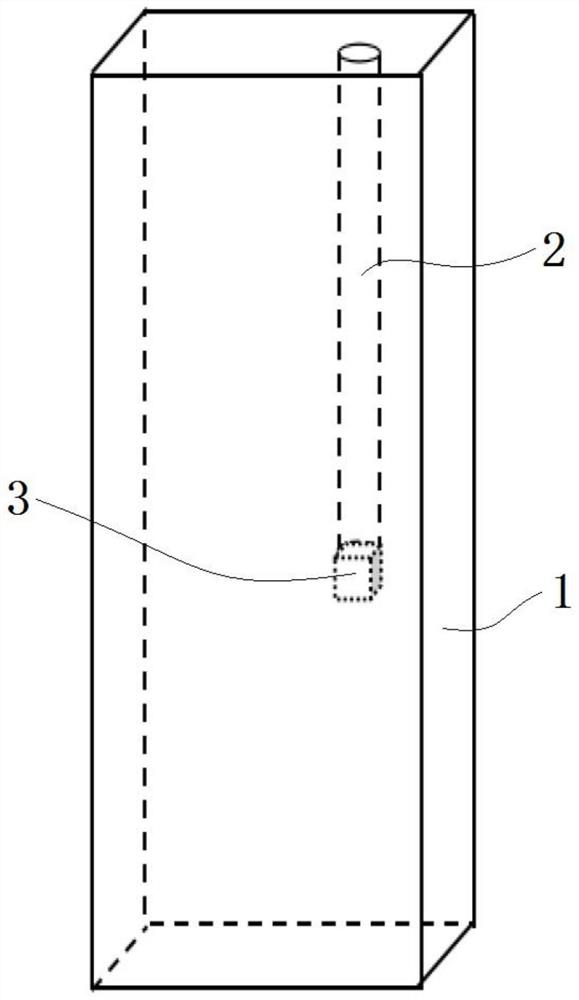

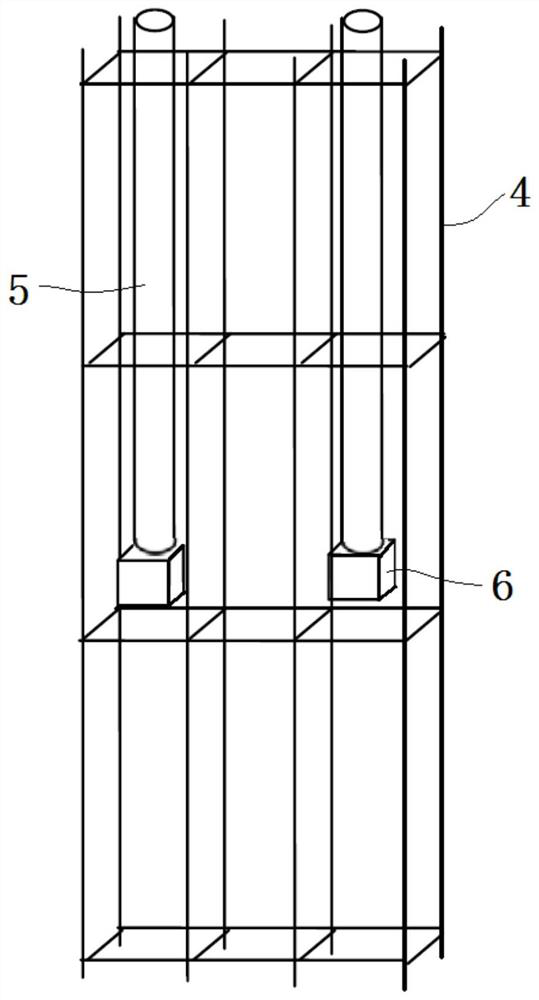

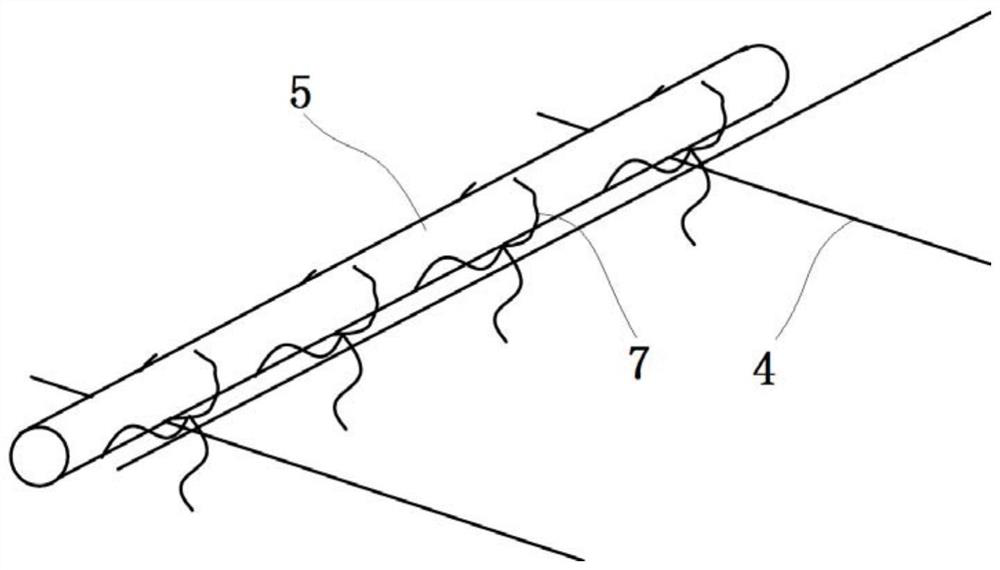

[0029] An absorption-type ALC plate pipeline integrated production method. Firstly, after the rod-shaped loose body 5 and the block-shaped loose body 6 are manufactured in the steel cage 4, they are fixed on the designed position of the steel cage 4 with the fixing clip 7, immersed in the ALC slurry. The poured mold is sent to the rest room for rest (the temperature of the rest room is 55°C-60°C, normal pressure), then cut, and then sent to the steam curi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com