Method used for preparing aluminium-doped zinc oxide thin film via electroless deposition

An aluminum-doped zinc oxide, electroless deposition technology, applied in the direction of liquid chemical plating, metal material coating process, coating, etc., can solve the problems of flexible substrates that are not resistant to high temperature and do not have electrical conductivity, etc. High temperature resistance, low cost and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

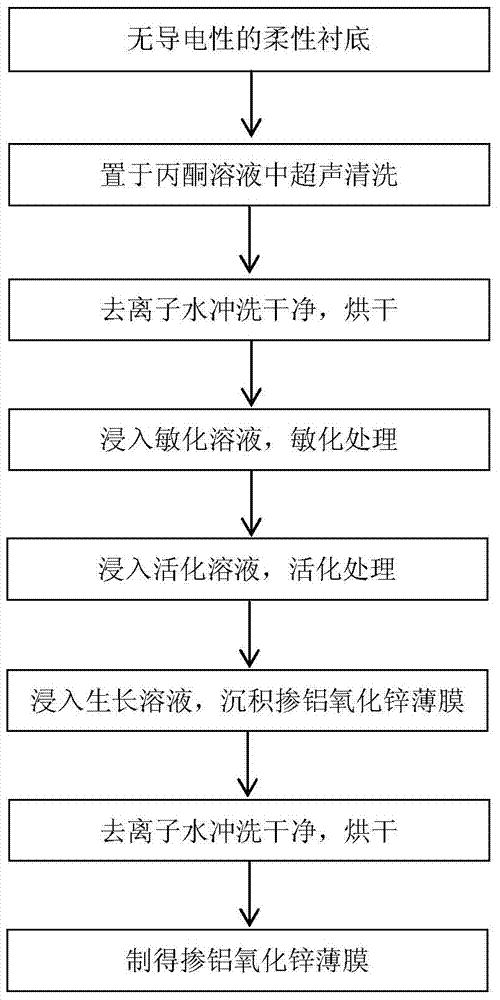

[0020] The method for preparing the electroless deposition aluminum-doped zinc oxide thin film of the present invention comprises the following steps:

[0021] (1) Place the non-conductive flexible substrate in an acetone solution for ultrasonic cleaning for 20 minutes, then rinse it with deionized water, and dry it to obtain a clean flexible substrate;

[0022] (2) At room temperature, sensitize the clean flexible substrate by immersing it in the sensitizing solution for 45 minutes to obtain a sensitized flexible substrate; the sensitizing solution is composed of SnCl 2 and HCl solution, SnCl in the sensitization solution 2 The concentration of HCl is 20g / l, and the concentration of HCl is 0.12mol / l. The sensitization treatment is to make the non-conductive flexible substrate surface absorb sensitization particles Sn 2+ ;

[0023] (3) At room temperature, immerse the sensitized flexible substrate in the activation solution for 45 minutes for activation treatment to obtain a...

Embodiment 2

[0026] Another example of the method for preparing the electroless deposition aluminum-doped zinc oxide thin film of the present invention comprises the following steps:

[0027] (1) Place the non-conductive flexible substrate in an acetone solution for ultrasonic cleaning for 15 minutes, then rinse it with deionized water, and dry it to obtain a clean flexible substrate;

[0028] (2) At room temperature, sensitize the clean flexible substrate by immersing it in the sensitizing solution for 60 minutes to obtain a sensitized flexible substrate; the sensitizing solution is composed of SnCl 2 and HCl solution, SnCl in the sensitization solution 2 The concentration of HCl is 40g / l, the concentration of HCl is 0.24mol / l, and the described sensitization treatment is to make the non-conductive flexible substrate surface adsorb the sensitized particles Sn 2+ ;

[0029] (3) At room temperature, immerse the sensitized flexible substrate in the activation solution for 60 minutes for ac...

Embodiment 3

[0032] Another example of the method for preparing the electroless deposition aluminum-doped zinc oxide thin film of the present invention comprises the following steps:

[0033] (1) Place the non-conductive flexible substrate in an acetone solution for ultrasonic cleaning for 10 minutes, then rinse it with deionized water, and dry it to obtain a clean flexible substrate;

[0034] (2) At room temperature, sensitize the clean flexible substrate by immersing it in the sensitizing solution for 30 minutes to obtain a sensitized flexible substrate; the sensitizing solution is composed of SnCl 2 and HCl solution, SnCl in the sensitization solution 2The concentration of HCl is 60g / l, and the concentration of HCl is 0.36mol / l. The sensitization treatment is to make the non-conductive flexible substrate surface adsorb sensitization particles Sn 2+ ;

[0035] (3) At room temperature, immerse the sensitized flexible substrate in the activation solution for 30 minutes for activation tre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com