Conductive ceramic powder-based polyimide conductive rubber and preparation method thereof

A polyimide type, conductive ceramic technology, applied in the direction of conductive adhesives, adhesives, non-polymer adhesive additives, etc., can solve the problems of poor mechanical properties and heat resistance of epoxy conductive adhesives, and achieve the goal of overcoming Low temperature resistance, overcoming poor stability, excellent stability and heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

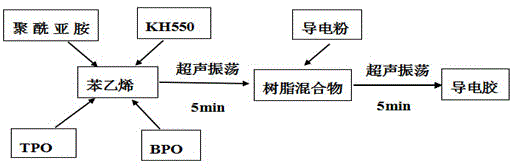

Image

Examples

Embodiment 1

[0025] Embodiment 1: Conductive adhesive is configured according to the following formula in parts by mass:

[0026] Polymer matrix (polyimide): 100;

[0027] Conductive filler (rare earth modified calcium manganate powder): 40;

[0028] Thinner (styrene): 30;

[0029] Thermal curing agent (triethanolamine): 10;

[0030] Thermal Initiator (BPO): 4;

[0031] Photoinitiator (TPO): 2;

[0032] Curing accelerator (2-ethyl-4-methylimidazole): 2

[0033] Conductivity enhancer (polyethylene glycol 400): 2;

[0034] Silane coupling agent (KH-550): 2.

[0035] Weigh the amount of diluent styrene according to the designed amount, and then add the resin matrix polyimide, coupling agent KH550, photoinitiator BPO and thermal initiator TPO according to the designed amount. Oscillation is performed with an ultrasonic oscillator, and after ultrasonic oscillation for 5 minutes, a resin mixture with a viscosity much lower than that of the polyimide resin is obtained. Then add conductive...

Embodiment 2

[0036] Embodiment 2: configure the conductive adhesive according to the following formula in parts by mass:

[0037] Polymer matrix (polyimide): 100;

[0038] Conductive filler (rare earth modified calcium manganate powder): 50;

[0039] Thinner (styrene): 40;

[0040] Thermal curing agent (triethanolamine): 10;

[0041] Thermal Initiator (BPO): 4;

[0042] Photoinitiator (TPO): 2;

[0043] Curing accelerator (2-ethyl-4-methylimidazole): 2;

[0044] Conductivity accelerator (polyethylene glycol 400): 1;

[0045] Silane coupling agent (KH-550): 2.

[0046] Weigh the amount of diluent styrene according to the designed amount, and then add the resin matrix polyimide, coupling agent KH550, photoinitiator BPO and thermal initiator TPO according to the designed amount. Oscillation is performed with an ultrasonic oscillator, and after ultrasonic oscillation for 5 minutes, a resin mixture with a viscosity much lower than that of the polyimide resin is obtained. Then add conduc...

Embodiment 3

[0047] Embodiment 3: configure the conductive adhesive according to the following formula in parts by mass:

[0048] Polymer matrix (polyimide): 100;

[0049] Conductive filler (rare earth modified calcium manganate powder): 40;

[0050] Thinner (styrene): 40;

[0051] Thermal curing agent (triethanolamine): 10;

[0052] Thermal Initiator (BPO): 4;

[0053] Photoinitiator (TPO): 2;

[0054] Curing accelerator (2-ethyl-4-methylimidazole): 2;

[0055] Conductivity accelerator (polyethylene glycol 400): 1;

[0056] Silane coupling agent (KH-550): 2.

[0057] Weigh the amount of diluent styrene according to the designed amount, and then add the resin matrix polyimide, coupling agent KH550, photoinitiator BPO and thermal initiator TPO according to the designed amount. Oscillation is performed with an ultrasonic oscillator, and after ultrasonic oscillation for 5 minutes, a resin mixture with a viscosity much lower than that of the polyimide resin is obtained. Then add conducti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com