Preparation method for sintering resistant thermal barrier ceramic coating structure

A ceramic coating and thermal barrier technology, applied in the field of thermal barrier coating preparation, can solve the problems of low temperature resistance, easy sintering, high thermal conductivity, etc., achieve high fracture toughness, low cost, and overcome the problems of low thermal conductivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

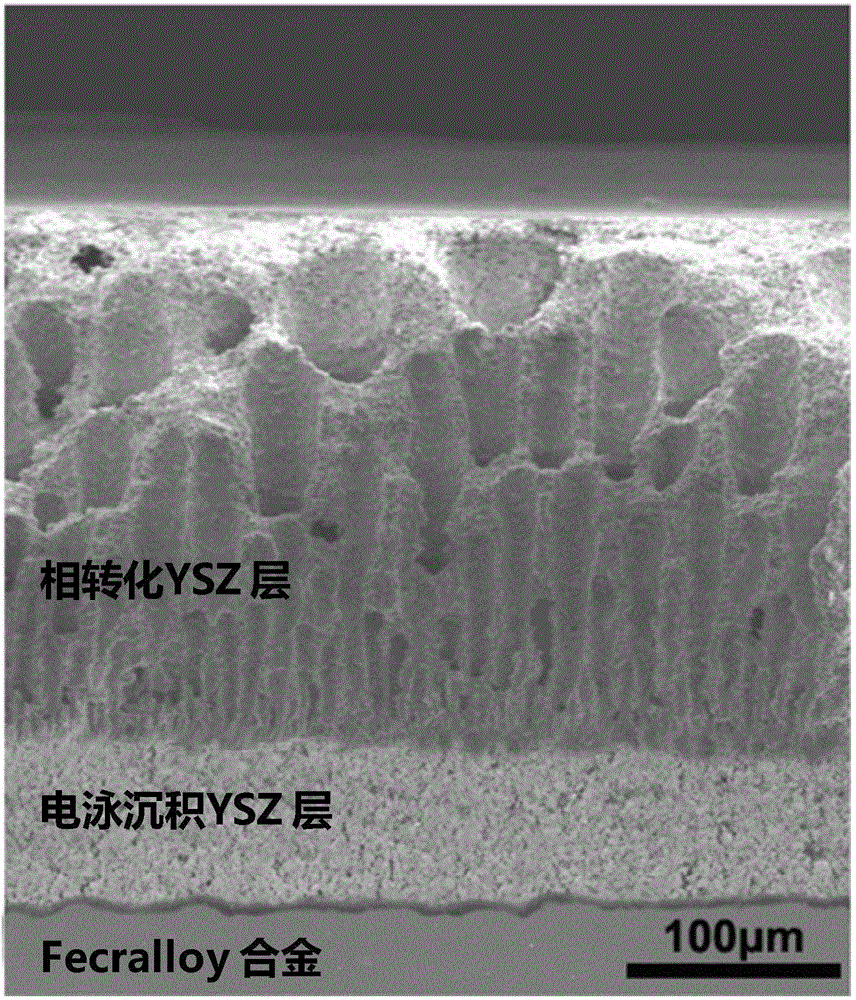

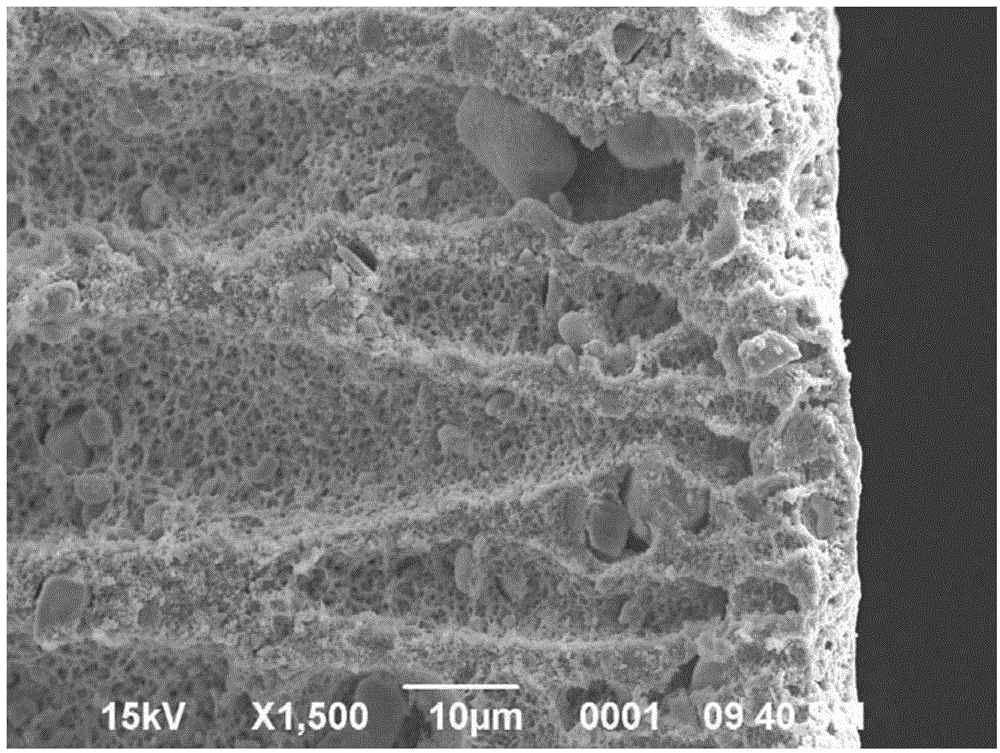

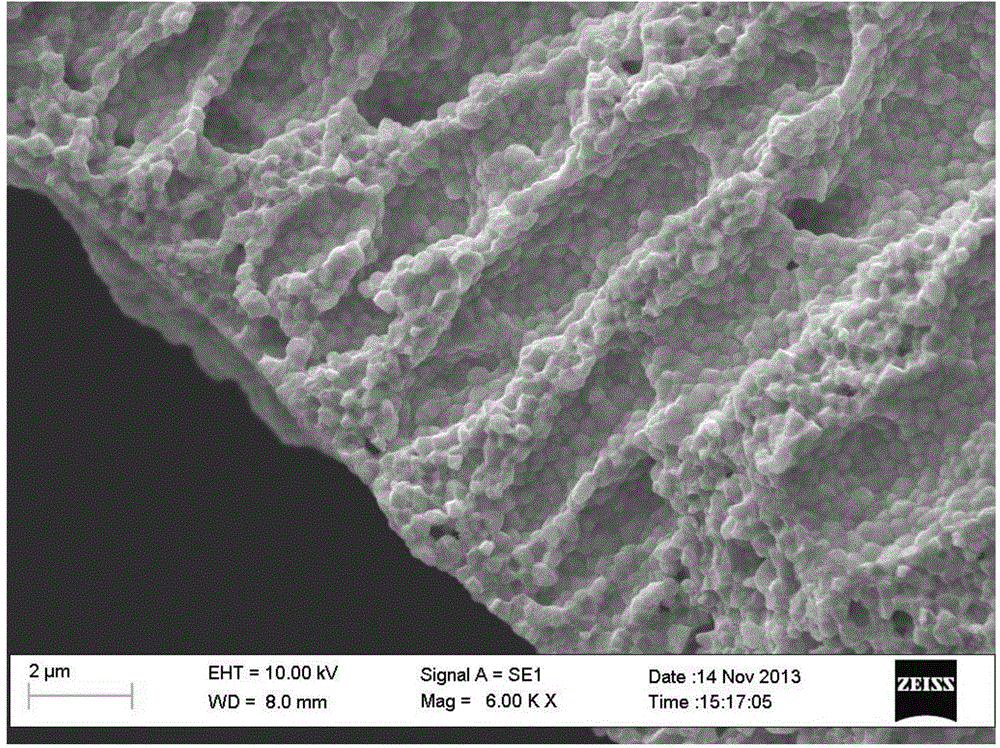

[0031] Step 1: Electrophoretic coating preparation

[0032]First prepare a stable suspension for electrophoretic deposition, in which YSZ and iron oxide (Fe2O3) powders are ball milled in proportion to obtain uniformly mixed YSZ / Fe2O3 powders, and then the mass concentration of YSZ / Fe2O3 powders in the solvent is 40Kg / m3 . The solvent is a mixed solution of ethanol and deionized water, in which the volume ratio of ethanol and deionized water is 4:1, and the concentration of 0.1mol / L acetic acid is used to adjust the surface charge of YSZ particles in the suspension to prevent the aggregation of YSZ particles , the pH of the solution was adjusted to 2.0. Before the electrophoretic deposition process, the suspension was stirred for 2 minutes with an ultrasonic stirrer. During the deposition process, the anode was made of graphite plate, and the cathode was made of the target superalloy Fecralloy. The distance between the cathode and the anode was 10mm. The electrophoretic depos...

Embodiment 2

[0040] Step 1: Electrophoretic coating preparation

[0041] First prepare a stable suspension for electrophoretic deposition, in which YSZ and iron oxide (Fe2O3) powders are ball milled in proportion to obtain uniformly mixed YSZ / Fe2O3 powders, and then the mass concentration of YSZ / Fe2O3 powders in the solvent is 100Kg / m3 . The solvent is a mixed solution of ethanol and deionized water, in which the volume ratio of ethanol and deionized water is 4:1, and the concentration of 0.1mol / L acetic acid is used to adjust the surface charge of YSZ particles in the suspension to prevent the aggregation of YSZ particles , the pH of the solution was adjusted to 2.0. Before the electrophoretic deposition process, the suspension was stirred for 10 minutes with an ultrasonic stirrer. During the deposition process, the anode was made of graphite plate, and the cathode was made of the target superalloy Fecralloy. The distance between the cathode and the anode was 10mm. The electrophoretic de...

Embodiment 3

[0049] Step 1: Electrophoretic coating preparation

[0050] First prepare a stable suspension for electrophoretic deposition, in which YSZ and iron oxide (Fe2O3) powders are ball milled in proportion to obtain uniformly mixed YSZ / Fe2O3 powders, and then the mass concentration of YSZ / Fe2O3 powders in the solvent is 100Kg / m3 . The solvent is a mixed solution of ethanol and deionized water, in which the volume ratio of ethanol and deionized water is 4:1, and the concentration of 0.1mol / L acetic acid is used to adjust the surface charge of YSZ particles in the suspension to prevent the aggregation of YSZ particles , the pH of the solution was adjusted to 2.0. Before the electrophoretic deposition process, the suspension was stirred for 10 minutes with an ultrasonic stirrer. During the deposition process, the anode was made of graphite plate, and the cathode was made of the target superalloy Fecralloy. The distance between the cathode and the anode was 10 mm. The electrophoretic d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com