Flame-retardant electromagnetic shielding fabric and preparation method thereof

An electromagnetic shielding and fabric technology, applied in the direction of fabrics, textiles, knitting, etc., can solve the problems that are not suitable for wearing comfort performance requirements, difficult to use high temperature flame retardancy, etc., to achieve excellent electromagnetic shielding effect, good high temperature flame retardancy, and comfortable wearing good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

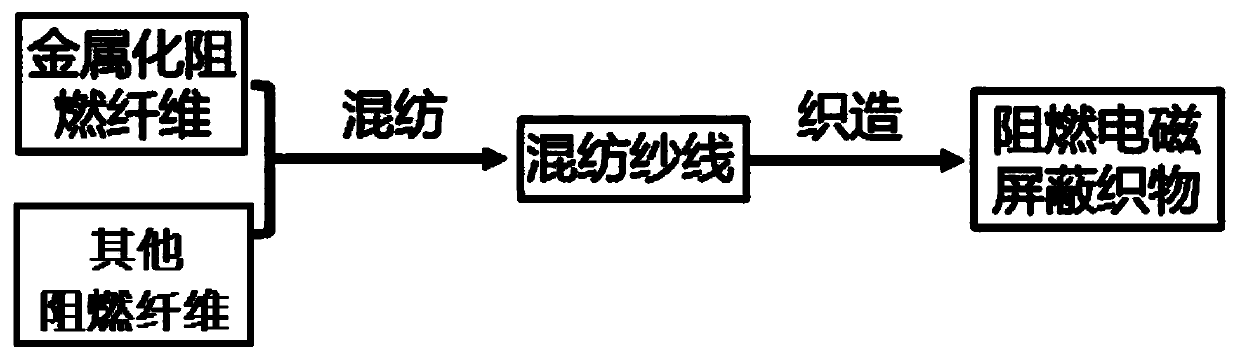

Method used

Image

Examples

specific Embodiment 1

[0035] (1) silver-plated aramid fiber 1313 fiber (silver content 30wt.%, base material is DuPont Nomex) and aramid fiber 1313 fiber (DuPont Nomex) according to the ratio of 30:70 according to the mass ratio, through opening, carding, pulling Stretching, twisting and winding processes, spinning into Nm52 / 2 yarns;

[0036] (2) adopt arrow shaft loom, according to warp density 205, weft density 205 is woven into plain weave;

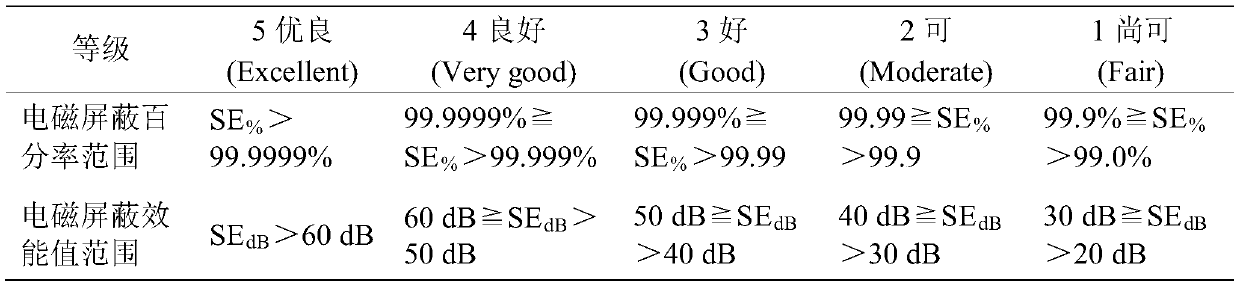

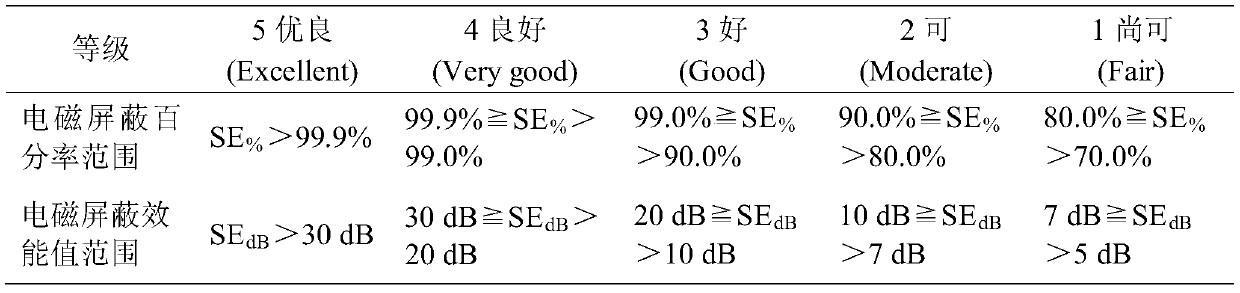

[0037] (3) Test the flame retardant performance and electromagnetic shielding performance of the fabric, and the data are shown in Table 3.

specific Embodiment 2

[0039] (1) Silver-plated aramid fiber 1313 fiber (silver content 30wt.%, base material is DuPont Nomex) and aramid fiber 1313 fiber (DuPont Nomex) according to the ratio of mass ratio 30:70, through opening, carding, drafting , twisting, winding and other processes, spinning into Nm52 / 2 yarns;

[0040] (2) adopt arrow shaft loom, according to warp density 200, weft density 205 is woven into twill fabric;

[0041] (3) Test the flame retardant performance and electromagnetic shielding performance of the fabric, the data are shown in Table 3.

specific Embodiment 3

[0043](1) Silver-plated aramid fiber 1313 fiber (silver content 30wt.%, base material is DuPont Nomex) and aramid fiber 1313 fiber (DuPont Nomex) according to the ratio of mass ratio 50:50, through opening, carding, drafting , twisting and winding processes, spinning into Nm52 / 2 yarns;

[0044] (2) adopt arrow shaft loom, according to warp density 205, weft density 205 is woven into plain weave;

[0045] (3) Test the flame retardant performance and electromagnetic shielding performance of the fabric, the data are shown in Table 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com