Silicone rubber/hindered phenol composite modified butyl chloride damping rubber and preparation method thereof

A technology of compound modification of chlorinated butyl rubber, which is applied in the field of damping materials, and achieves the effects of being economical and practical, expanding the scope of use, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] 1. Preparation of hindered phenol modified hydroxyl-terminated polysiloxane:

[0046] Under the protection of nitrogen gas, 80g hydroxyl-terminated polysiloxane (also known as: hydroxyl-terminated polysiloxane), 40g 3,5-bis(tert-butyl)-4-hydroxyphenylpropionyl chloride and 0.3g iron catalyst ( For example: skeleton iron) was stirred and reacted at 120°C for 4 hours, the reaction was terminated, unreacted substances were removed, and the obtained product was dried at 40°C for 3 hours to obtain hindered phenol-modified hydroxyl-terminated polysiloxane for future use.

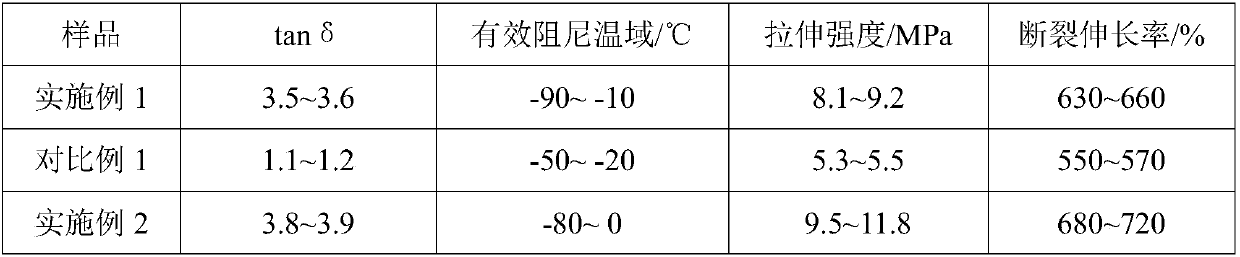

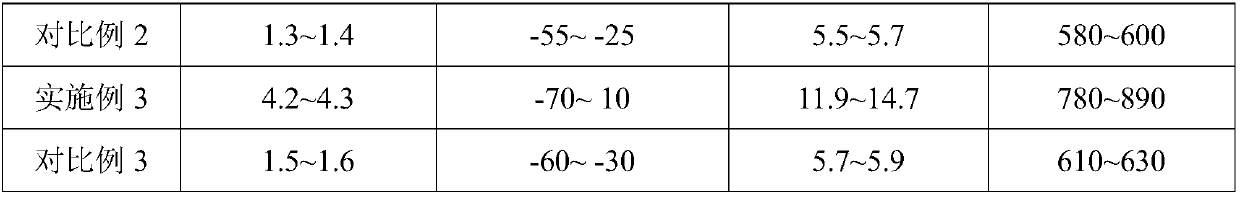

[0047] The performance test data of the prepared hindered phenol-modified hydroxyl-terminated polysiloxane are shown in Table 1.

[0048] 2. Preparation of silicone rubber / hindered phenol compound modified chlorinated butyl damping rubber:

[0049] a) first adjust the roll distance of the open mill to 2mm, then put 100g of chlorinated butyl rubber matrix, 50g of methyl vinyl silicone rubber raw rubber, and...

Embodiment 2

[0058] 1. Preparation of hindered phenol modified hydroxyl-terminated polysiloxane:

[0059] Under the protection of nitrogen gas, 90g hydroxyl-terminated polysiloxane (also known as: hydroxyl-terminated polysiloxane), 45g 3,5-bis(tert-butyl)-4-hydroxyphenylpropionyl chloride and 0.4g cobalt catalyst ( For example: Skeleton cobalt) was stirred and reacted at 130°C for 3 hours, the reaction was completed, unreacted substances were removed, and the obtained product was dried at 50°C for 2.5 hours to obtain hindered phenol-modified hydroxyl-terminated polysiloxane for future use.

[0060] The performance test data of the prepared hindered phenol-modified hydroxyl-terminated polysiloxane are shown in Table 1.

[0061] 2. Preparation of silicone rubber / hindered phenol compound modified chlorinated butyl damping rubber:

[0062] a) first adjust the roll distance of the open mill to 3mm, then put 100g of chlorinated butyl rubber matrix, 60g of methyl vinyl silicone rubber raw rubber...

Embodiment 3

[0071] 1. Preparation of hindered phenol modified hydroxyl-terminated polysiloxane:

[0072] Under the protection of nitrogen gas, 100g hydroxyl-terminated polysiloxane (also known as: hydroxyl-terminated polysiloxane), 50g 3,5-bis(tert-butyl)-4-hydroxyphenylpropionyl chloride and 0.5g nickel catalyst ( For example: framework nickel) stirred and reacted at 140°C for 2 hours,

[0073] Finish the reaction, remove unreacted substances, and dry the obtained product at 60°C for 2 hours to obtain hindered phenol-modified hydroxyl-terminated polysiloxane, which is ready for use.

[0074] The performance test data of the prepared hindered phenol-modified hydroxyl-terminated polysiloxane are shown in Table 1.

[0075] 2. Preparation of silicone rubber / hindered phenol compound modified chlorinated butyl damping rubber:

[0076] a) first adjust the roll distance of the open mill to 4mm, then put 100g of chlorinated butyl rubber matrix, 70g of methyl vinyl silicone rubber raw rubber, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com