Patents

Literature

44results about How to "The preparation process is economical and practical" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Water-based coating containing graphene/zinc-aluminum hydrotalcite nano composition and preparation method thereof

InactiveCN106995643AImprove compatibilitySolve reunionFireproof paintsAnti-corrosive paintsWater basedDefoaming Agents

The invention discloses water-based coating containing a graphene / zinc-aluminum hydrotalcite nano composition and a preparation method thereof. The water-based coating is prepared from the following components in parts by weight: 30 to 50 parts of water-based resin, 25 to 40 parts of water, 0.1 to 0.5 part of dispersing agent, 0.1 to 0.5 part of wetting agent, 0.1 to 0.5 part of defoaming agent, 0.1 to 0.5 part of thickening agent, 0.1 to 0.5 part of film forming aids, 0 to 10 parts of curing agent, 0 to 25 parts of titanium dioxide, 0 to 20 parts of calcium carbonate, and 0.1 to 2.5 parts of graphene / zinc-aluminum hydrotalcite nano composition. The graphene / zinc-aluminum hydrotalcite nano composition is added into the water-based coating, so that the high temperature resistance, the corrosion resistance, the flame retardant property, the weather resistance, the impact resistance, the abrasion resistance, the hardness and the obstruction property of the water-based coating are significantly improved, and the multiple functions of the water-based coating are improved.

Owner:东营聚强新材料有限责任公司

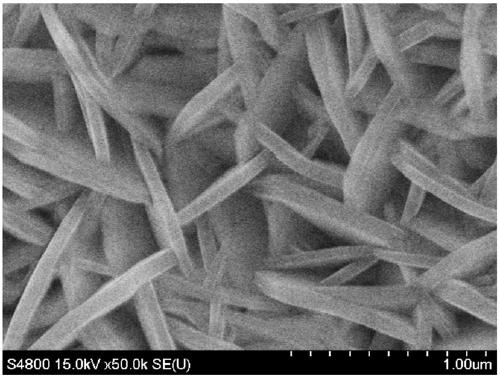

Supported nickel-based alloy catalyst as well as preparation method and application thereof

PendingCN109675569AStable structureThe structure is economical and practicalOrganic compound preparationCarboxylic acid esters preparationIndiumHigh activity

The invention discloses a supported nickel-based alloy catalyst as well as a preparation method and application thereof. The supported nickel-based alloy catalyst comprises a carrier and a nickel-based alloy supported by the carrier. The nickel-based alloy is a NixMyCz alloy, wherein x is greater than or equal to 1 and less than or equal to 10, y is greater than or equal to 1 and less than or equal to 10, and z is greater than or equal to 0 and less than or equal to 5; M is selected from at least one of iron, copper, cobalt, zinc, molybdenum, palladium, silver, gallium, indium, tin, germanium,bismuth and lead; in addition, when z is greater than 0, M is not indium, the total mass of the nickel-based alloy is 1 to 50 percent, and the balance is a carrier. The catalyst provided by the invention has the advantages of stable structure, good thermal conductivity, high permeability, high conversion rate, high selectivity, high activity, high mechanical strength, easiness in forming and filling, high throughput, low pressure drop and the like. The supported nickel-based alloy catalyst is a good catalyst for reactions for preparing methyl glycollate, ethylene glycol and ethanol by hydrogenation of dimethyl oxalate.

Owner:EAST CHINA NORMAL UNIV

Rose essential oil microcapsule emulsion, and preparation method and application thereof

ActiveCN110511603AAvoid lostExtended service lifeAntifouling/underwater paintsPaints with biocidesWater basedEmulsion

The invention discloses a rose essential oil microcapsule emulsion, and a preparation method and application thereof. The rose essential oil microcapsule emulsion is prepared a wall material A, a wallmaterial B and a core material through blending, emulsifying and crosslinking, wherein the wall material A is Arabic gum, gelatin or chitosan, the wall material B is polyvinyl alcohol or sodium alginate, and the core material is rose essential oil. A water-based coating containing the rose essential oil microcapsule can be prepared by adding the rose essential oil microcapsule emulsion into a water-based coating. The rose essential oil microcapsule emulsion prepared in the invention is long in service life, good in slow release effect, good in durability, high in compatibility with a coatingand easy to be uniformly dispersed in the coating; moreover, due to the unique pharmacological properties and bactericidal action of the rose essential oil, the water-based coating containing the roseessential oil microcapsule can effectively avoid the use of bactericides in the coating, is safe and environment-friendly, and has good conditioning effect on people with long-term insomnia and irritable mood.

Owner:SHANGHAI UNIV OF ENG SCI

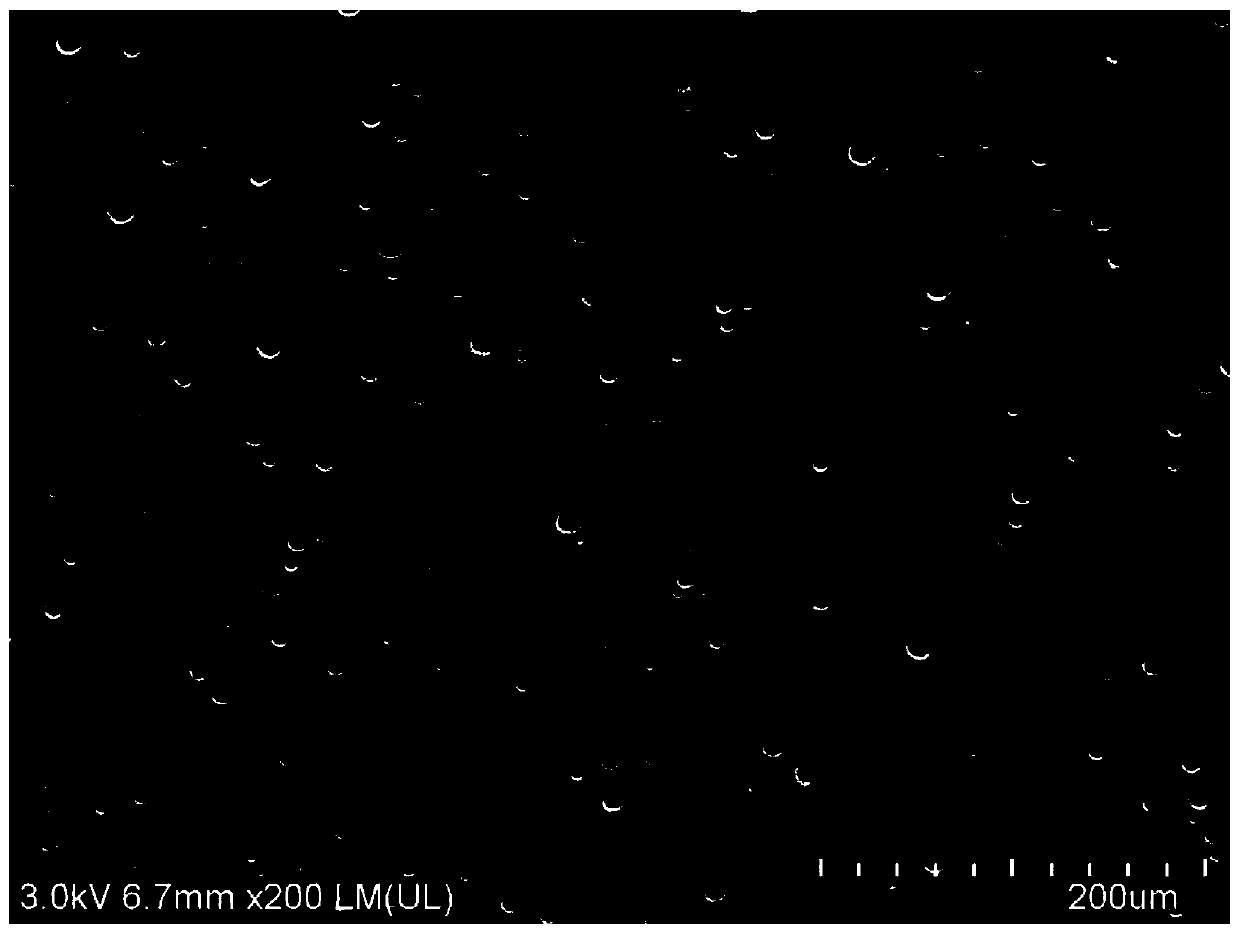

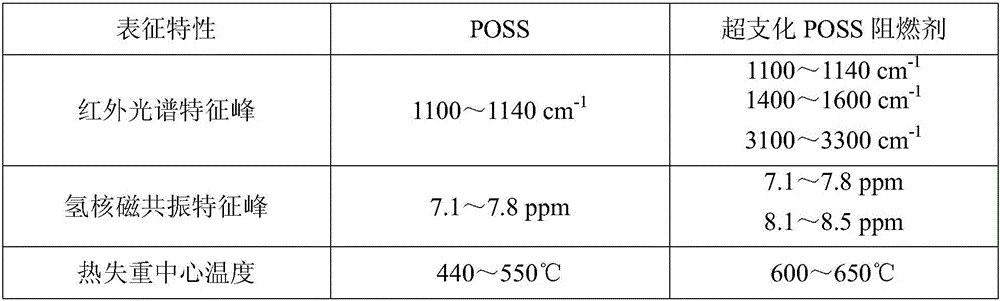

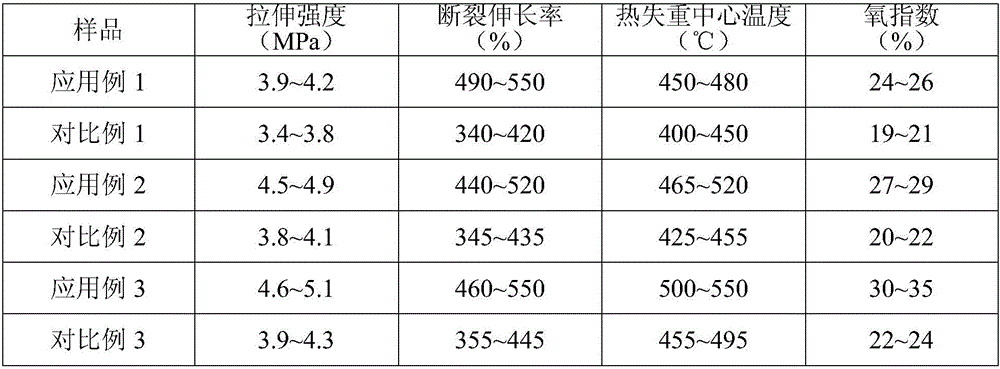

Hyperbranched POSS flame retardant and preparation method and applications thereof

The invention discloses a hyperbranched POSS flame retardant and a preparation method and applications thereof. The hyperbranched POSS flame retardant is prepared by the following steps: performing hydrolysis reaction on octaphenyl polyhedral silsesquioxane under alkaline condition to obtain heptaphenyl trisilihydroxyl polyhedral silsesquioxane, then reacting the heptaphenyl trisilihydroxyl polyhedral silsesquioxane with 1,3,5-trichlorobenzene to obtain a hyperbranched POSS intermediate, finally reacting the obtained hyperbranched POSS intermediate with AB2 monomer. Through tests, the flame retardance performance, mechanical performance, heat-insulating and smoke inhibition performances of a silicon rubber flame-retardant composite material of the hyperbranched POSS flame retardant are obviously improved, so that the hyperbranched POSS flame retardant has wide application prospects. In addition, the preparation technique is economic and practical, the preparation process is simple, the cost is low, special equipment and harsh conditions are not needed, large-scale production is easily realized, and high practical values can be achieved.

Owner:SHANGHAI UNIV OF ENG SCI

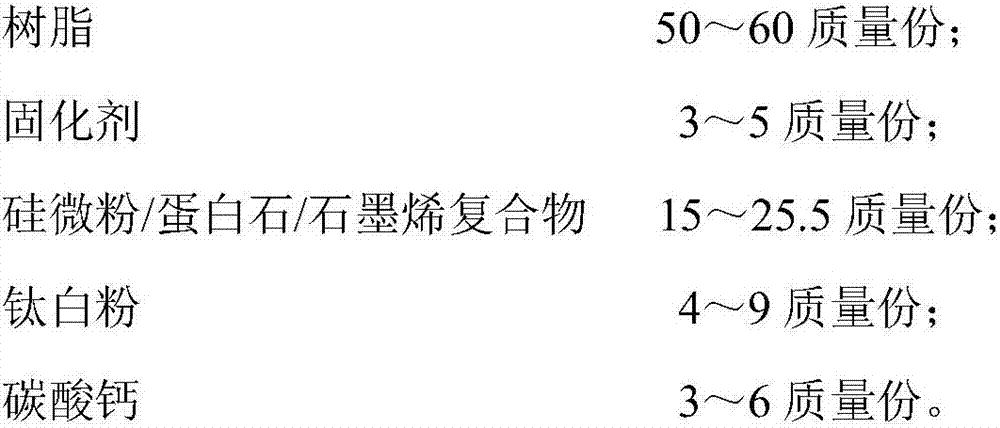

Functional type powdery paint and preparation method thereof

ActiveCN106916515AImproved release of negative ionsImprove the bactericidal effectPowdery paintsEpoxy resin coatingsTemperature resistanceMaterials science

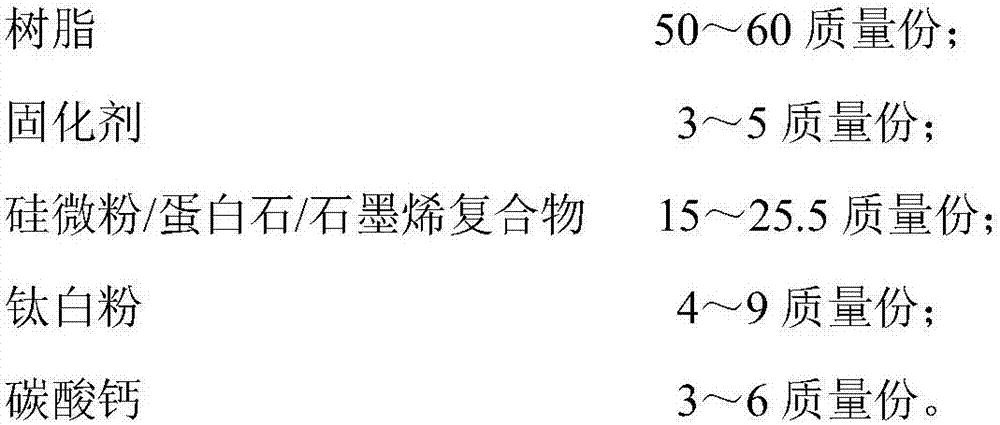

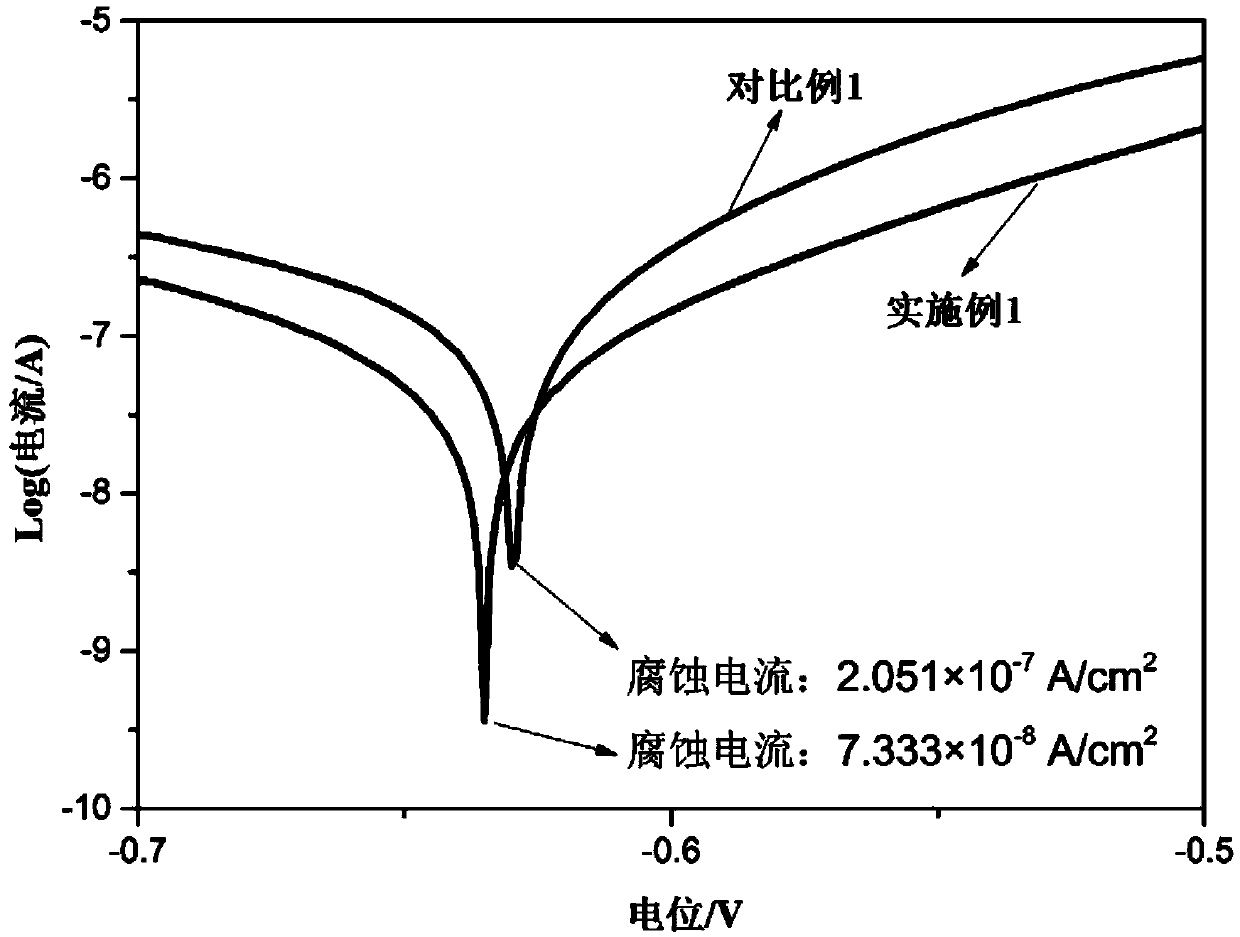

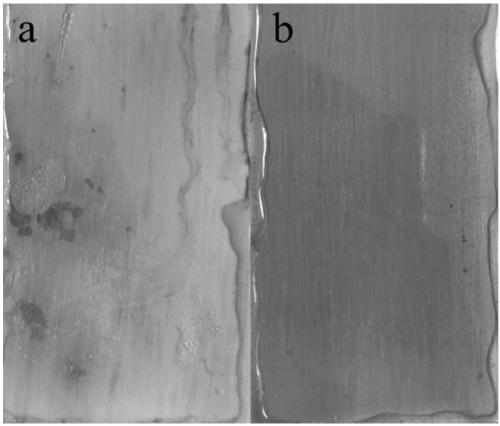

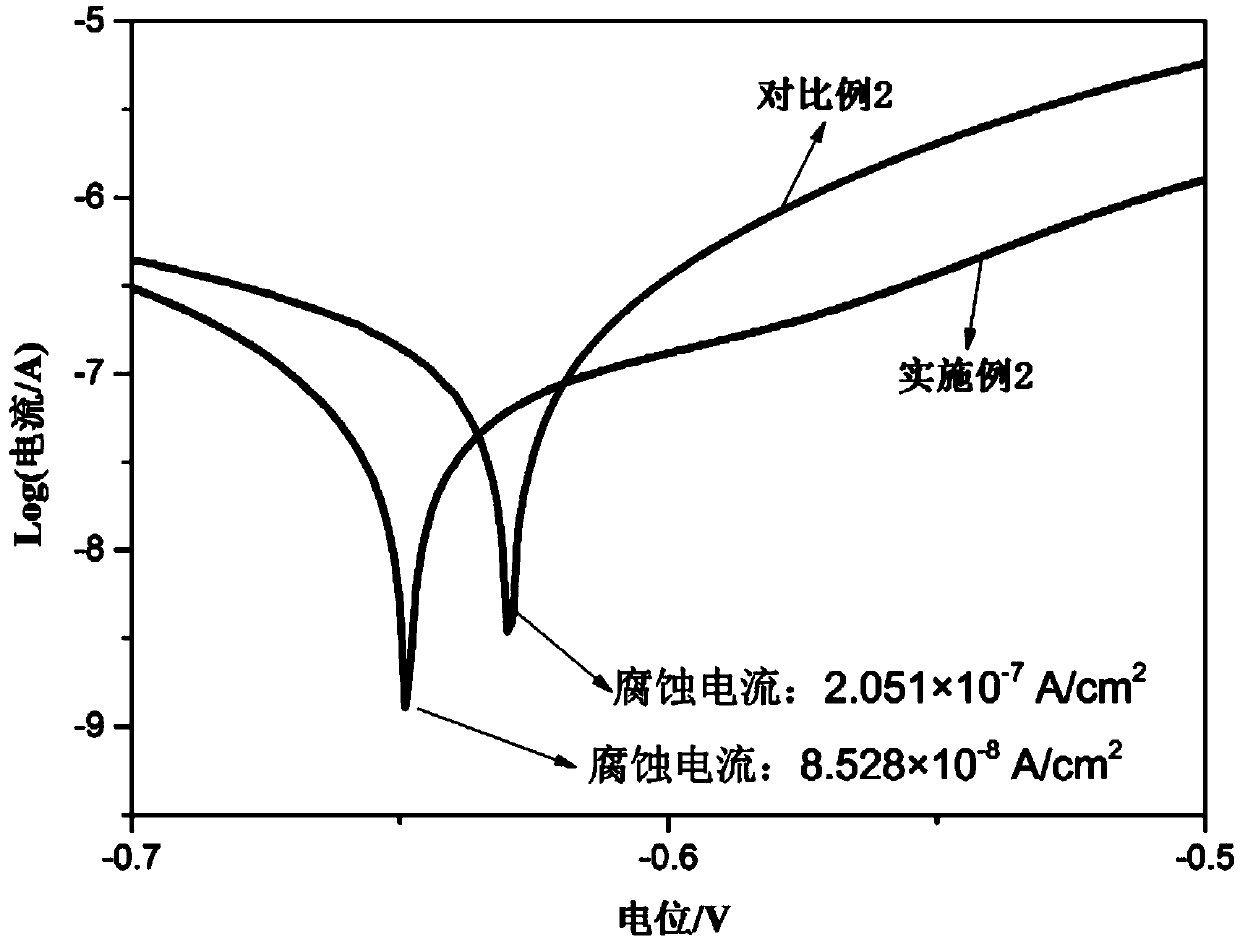

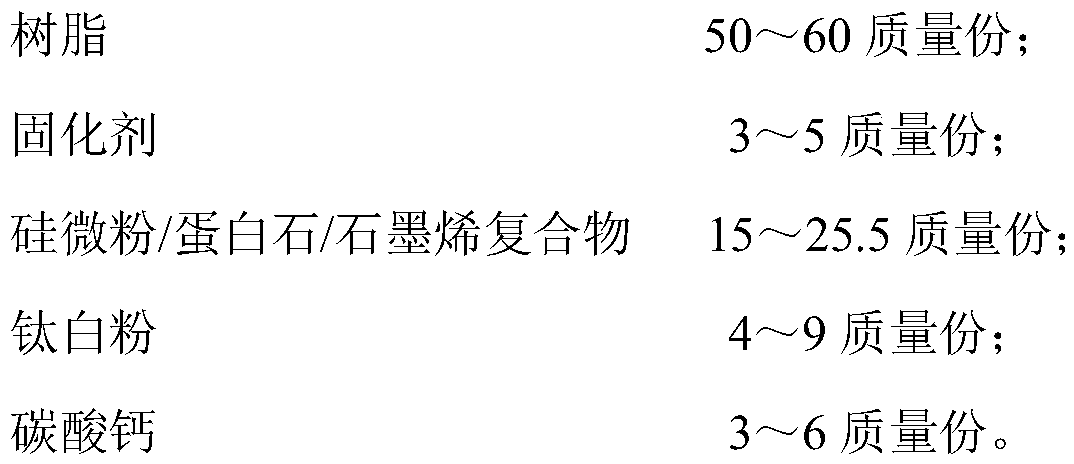

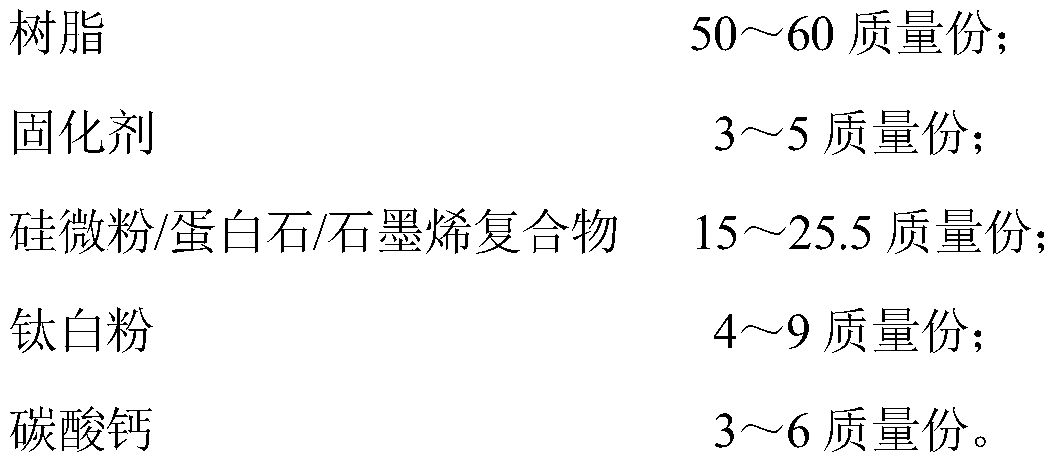

The invention discloses a functional type powdery paint and a preparation method thereof. The functional type powdery paint is composed of the following components in parts by weight: 50 to 60 parts of resin, 3 to 5 parts of curing agent, 15 to 25.5 parts of silica micro powder / opal / graphene composite, 4 to 9 parts of titanium dioxide, and 3 to 6 parts of calcium carbonate. By adding a silica micro powder / opal / graphene composite into the powdery paint, under the synergetic effect of silica micro powder, opal, and graphene, the functions of the powdery paint such as negative ion releasing, sterilizing, air purifying, and the like, are enhanced; at the same time, the properties such as high temperature resistance, corrosion resistance, impact resistance, wear resistance, hardness, and the like, are strengthened; the powdery paint is enabled to have multiple functions; the application range of the powdery paint is enlarged; furthermore, the preparation technology is economic and practical, the preparation process is simple, the cost is low, no any special instrument or severe condition is needed, and massive production can be realized easily.

Owner:SHANGHAI UNIV OF ENG SCI

Preparation method for chlorinated butyl damping rubber containing modified montmorillonite damping agent

ActiveCN105199249AEmbodies the damping and vibration reduction effectImprove damping effectRubber materialMontmorillonite

The invention relates to a preparation method for chlorinated butyl damping rubber containing a modified montmorillonite damping agent. The preparation method comprises the following five steps: preparation of organic modified montmorillonite; hydroxyl group protection of 4-allyl-2,6-dimethoxyphenol; preparation of 4-allyl-2,6-dimethoxyanisole modified montmorillonite; elimination of hydroxyl group protection of4-allyl-2,6-dimethoxyanisole modified organic montmorillonite; and preparation of the chlorinated butyl damping rubber containing the modified montmorillonite damping agent. Compared with the prior art, the preparation method provided by the invention improves the damping vibration attenuation effect of a rubber material. The preparation method is economic, practical and simple, has low cost, can easily realize large-scale production and has practicality.

Owner:SHANGHAI UNIV OF ENG SCI

Cellulose solvent, and preparation method and application thereof

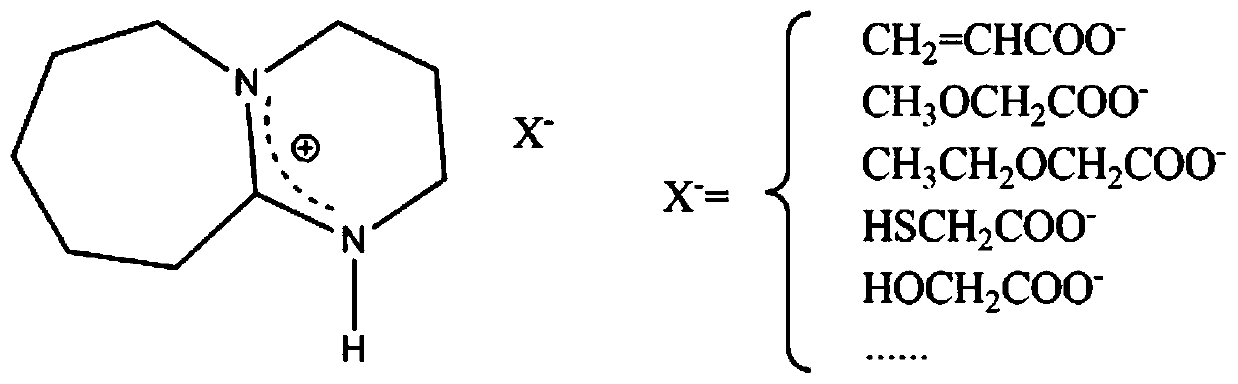

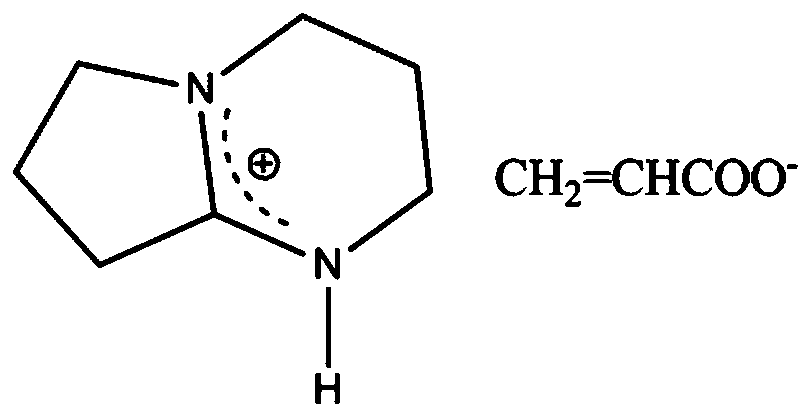

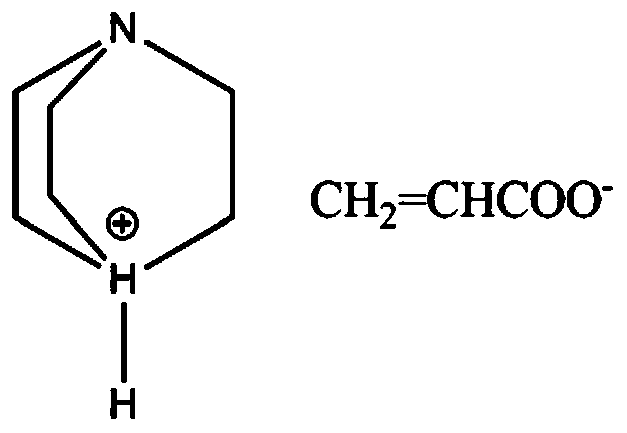

ActiveCN110256698AShorten the range of speciesShorten the scope of useBulk chemical productionCelluloseSolubility

The invention relates to a cellulose solvent, and a preparation method and application thereof. The preparation method for the cellulose solvent comprises the following steps of: mixing an organic base having a heterobicycle in its chemical structure with an organic solvent, placing the formed mixture in a three-necked flask, introducing nitrogen, dropwise adding an acidic reagent to a reaction system under magnetic stirring, and allowing a temperature to be kept at 30 DEG C or below in the whole reaction process so as to obtain a transparent mixture; continuing stirring the mixture at room temperature to realize full reaction of the mixture, allowing non-imidazole ionic liquid to be precipitated from an organic phase, and carrying out separation to obtain the non-imidazole ionic liquid; and heating the non-imidazole ionic liquid under the protection of an inert gas so as to obtain the dried cellulose solvent. According to the invention, the dissolution effect of cellulose in the relatively-inexpensive non-imidazole ionic liquid is improved through the preparation and utilization of the non-imidazole ionic liquid cellulose solvent; and in particular, the maximum solubility of cellulose is increased, the dissolution time of cellulose is shortened, and the degradation rate of cellulose is remarkablely reduced.

Owner:BEIJING FORESTRY UNIVERSITY

Water-based coil steel repair paint and preparation method thereof

ActiveCN109913072AGood alkali resistanceImprove corrosion resistanceAntifouling/underwater paintsPaints with biocidesWater basedAcrylic resin

Owner:SHANGHAI UNIV OF ENG SCI +1

Supramolecular montmorillonite-reinforced silica gel mold adhesive and preparation method thereof

The invention relates to a supramolecular montmorillonite-reinforced silica gel mold adhesive and a preparation method thereof. The supramolecular montmorillonite-reinforced silica gel mold adhesive is prepared from the following raw materials in parts by weight: 85-90 parts of vinyl-terminated polysiloxane containing UPy unit at side group, 5-10 parts of hydrogen-containing polysiloxane, 0.3-0.5 part of catalyst and 10-20 parts of modified montmorillonite. The preparation method comprises the following steps: a) proportionally adding the modified montmorillonite into the vinyl-terminated polysiloxane containing UPy unit at side group, and stirring for 40-60 minutes; b) adding the hydrogen-containing polysiloxane and catalyst, stirring uniformly, vacuumizing to eliminate bubbles, and carrying out curing reaction at the room temperature of 20-30 DEG C, thereby obtaining the supramolecular montmorillonite-reinforced silica gel mold adhesive. Compared with the prior art, a UPy self-identification pairing system, which has high hydrogen bond action, exists, so the silica gel mold adhesive has higher strength.

Owner:SHANGHAI UNIV OF ENG SCI

Intumescent flame retardant as well as preparation method and application thereof

The invention discloses an intumescent flame retardant as well as a preparation method and application thereof. The intumescent flame retardant is obtained by intercalating and modifying organic expanded vermiculite with a composite flame retardant; the composite flame retardant is prepared by compounding a charring catalyst, a foaming agent, a charring agent and diethyl hypophosphite; the organicexpanded vermiculite is obtained by firstly carrying out incomplete expansion calcination on vermiculite to obtain incomplete expanded vermiculite and then carrying out organic modification on the incomplete expanded vermiculite by adopting fatty acid or fatty acid salt. The intumescent flame retardant disclosed by the invention is good in compatibility with water-based resin; the intumescent flame retardant has good dispersity, hydrolysis resistance and migration resistance, the defects that a traditional flame retardant is poor in compatibility with a polymer, a paint film absorbs water easily and is poor in thermal stability are overcome, and the fireproof coating prepared from the intumescent flame retardant is good in fireproof and flame-retardant performance, high in adhesive force,high in hardness and good in coating water resistance and corrosion resistance.

Owner:SHANGHAI UNIV OF ENG SCI

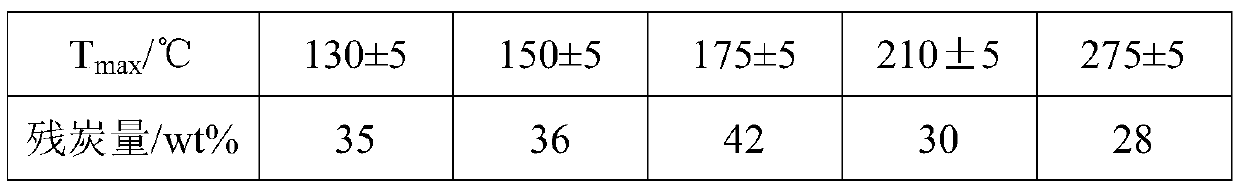

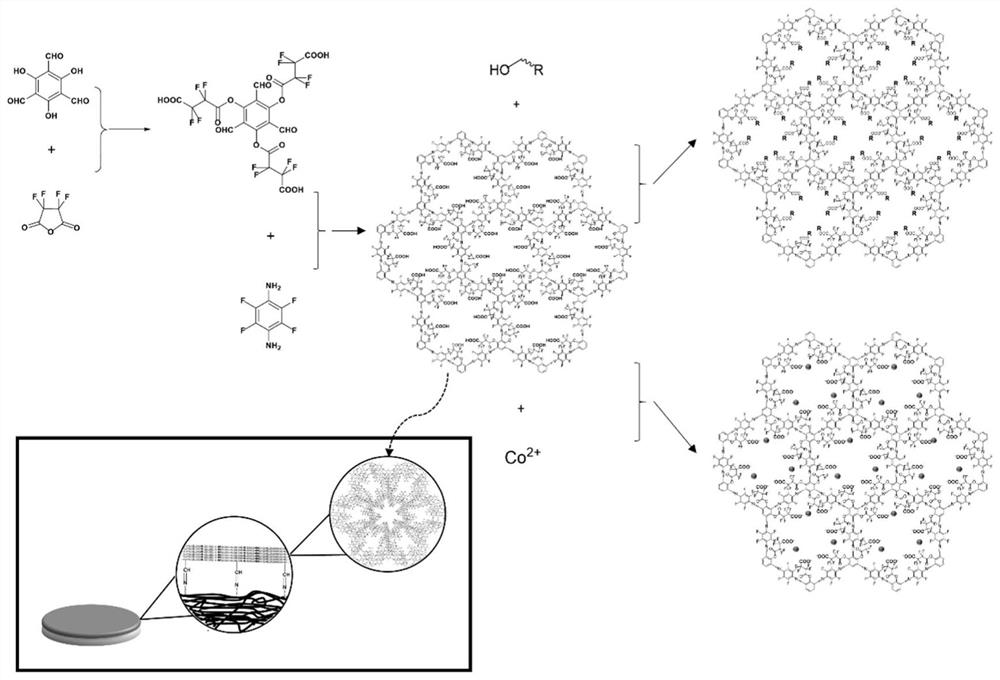

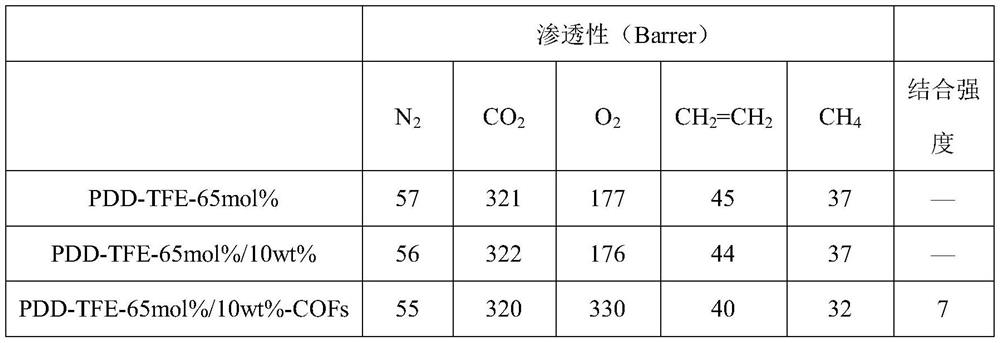

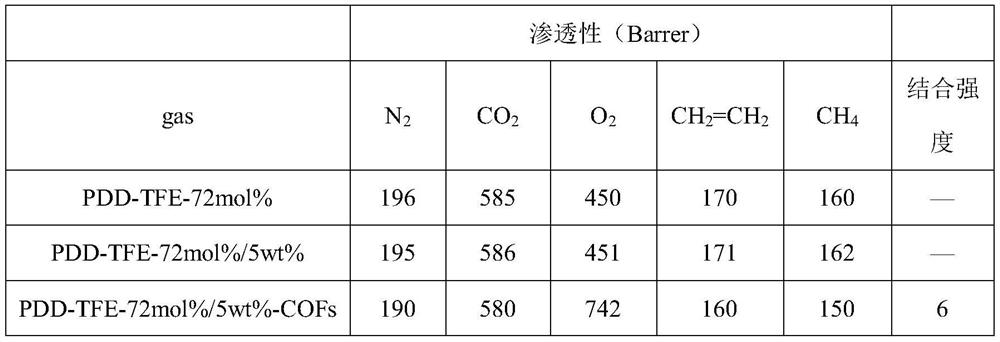

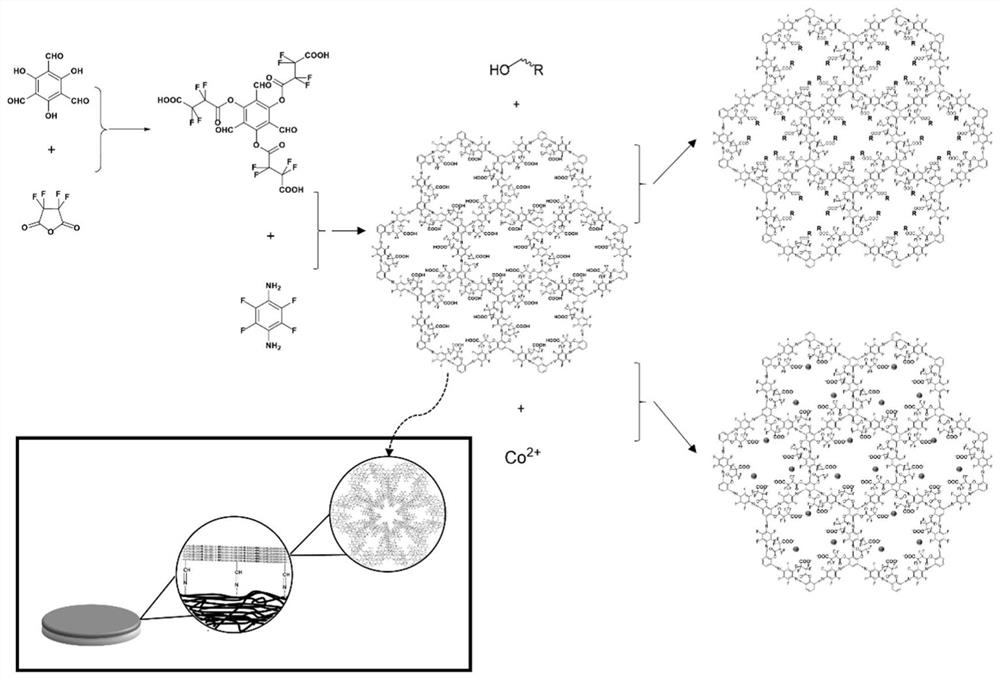

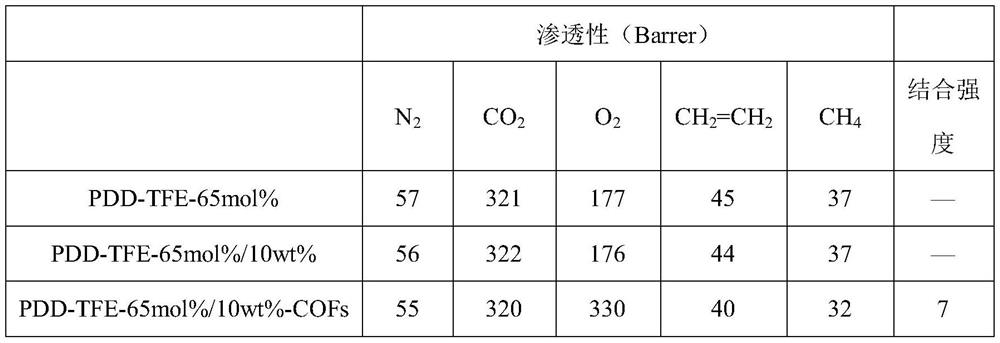

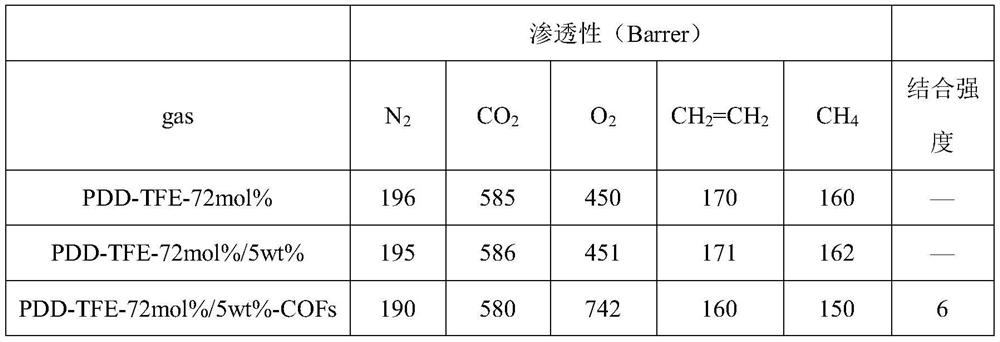

Composite separation membrane based on fluorine-containing copolymer and having in-situ grown organic framework structure and preparation method and application of composite separation membrane

ActiveCN113209836AGood compatibilityAperture size adjustableSemi-permeable membranesDispersed particle separationTetrafluoroethyleneAlkene

The invention discloses a composite separation membrane based on a fluorine-containing copolymer and having an in-situ grown organic framework and a preparation method and application of the composite separation membrane. The preparation method comprises the following steps: randomly copolymerizing perfluoro-2,2-dimethyl-1,3-dioxole (PDD), tetrafluoroethylene (TFE) and amine-terminated olefin according to a certain ratio to prepare a fluorine-containing copolymer which can be further subjected to reaction modification; mixing the fluorine-containing copolymer with a PDD-co-TFE binary copolymer according to different ratios to prepare a membrane; and performing Schiff base reaction to grow a covalent organic frame structure sheet layer in situ on the surface of a membrane matrix and introducing a functional group into a frame structure to form a coordination structure so as to obtain the fluorine-containing copolymer composite separation membrane. According to the composite separation membrane prepared by the method disclosed by the invention, binding force between a fluorine-containing copolymer layer and an organic framework structure layer is remarkably enhanced through amino bridging, and the adjustability of an internal pore size is realized through the modification of the internal structure of the pore channel of the organic framework structure layer, so organic gas and inorganic gas (oxygen, carbon dioxide and the like) can be efficiently and selectively separated; and the method has extremely high practical value.

Owner:ZHEJIANG UNIV +1

Modified diatomite/chlorinated butyl rubber damping composite and preparation method thereof

ActiveCN106810776AImproved damping propertiesImprove composite performanceNano zinc oxideStearic acid

The invention discloses modified diatomite / chlorinated butyl rubber damping composite and a preparation method thereof; the modified diatomite / chlorinated butyl rubber damping composite is prepared by mixing, by weight, 100 parts of chlorinated butyl rubber, 1-3 parts of a vulcanizing agent, 1-3 parts of an accelerator, 2-4 parts of stearic acid, 1-2 parts of nano zinc oxide, 2-4 parts of an antiaging agent, 1-3 parts of light weight magnesia, and 2.5-10 parts of modified diatomite; the modified diatomite is prepared by modifying sintered diatomite with hindered phenol. The modified diatomite is prepared by modifying diatomite with hindered phenol and is added to chlorinated butyl rubber, and the damping property, mechanical properties and heat conductivity of the chlorinated butyl rubber can be improved significantly; the modified diatomite / chlorinated butyl rubber damping composite has high practical value.

Owner:SHANGHAI UNIV OF ENG SCI

A kind of damping rubber and preparation method thereof

InactiveCN105801947BImprove damping effectIncrease dampingGroup 4/14 element organic compoundsRubber materialPolymer science

The invention relates to a damping rubber material and a preparing method thereof.The rubber material is prepared from, by weight, 100 parts of rubber matrix,10-20 parts of high molecular weight hindered phenol, 2-3 parts of vulcanizing agent, 2-3 parts of accelerant, 0.5-1.0 part of stearic acid, 1-3 parts of zinc oxide and 30-50 parts of carbon black.The raw materials are placed in an open mill according to the formula for mixing, and damping rubber containing high-molecular-weight hindered phenol is obtained after mixing, wherein the temperature of the open mill is set to be 155-165 DEG C, and mixing time is 45-60 min.Compared with the prior art, the material prepared with the method has the advantages that damping effect is good, the preparing technology is economical and practical, the preparing process is simple, cost is low, and large-scale production can be achieved easily.

Owner:SHANGHAI UNIV OF ENG SCI

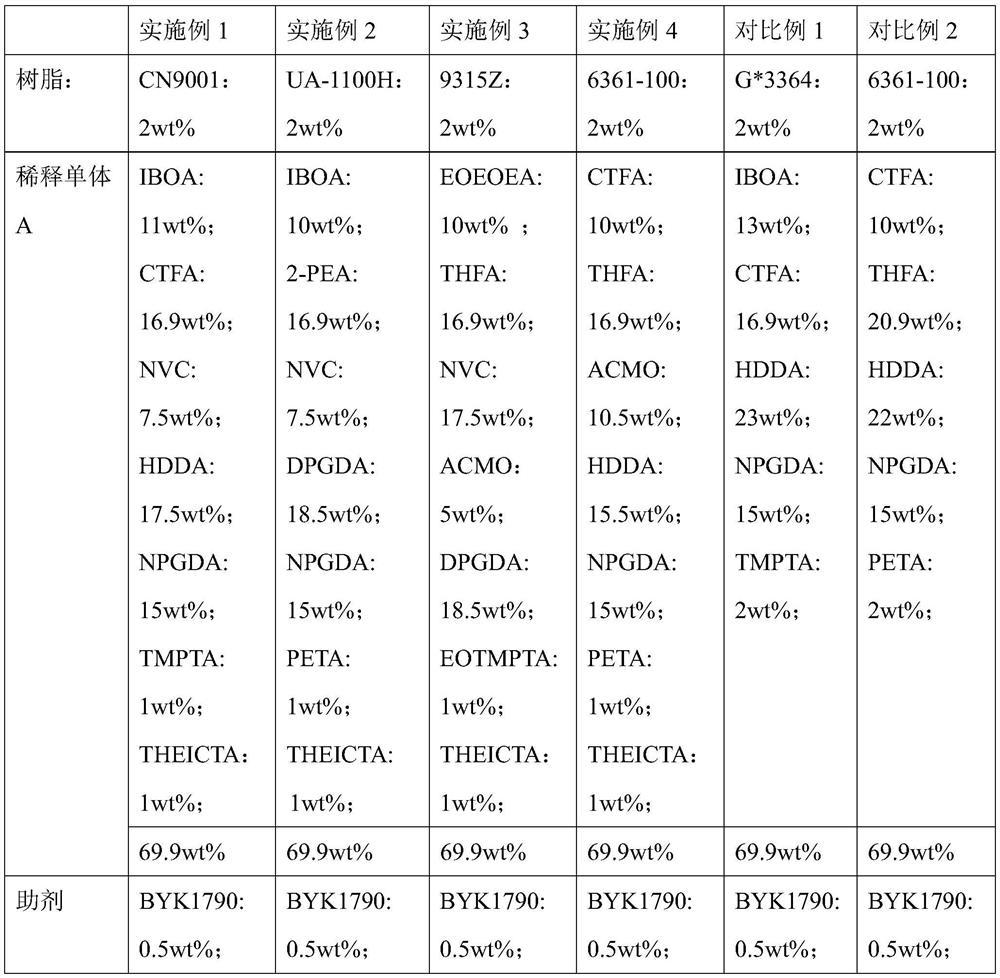

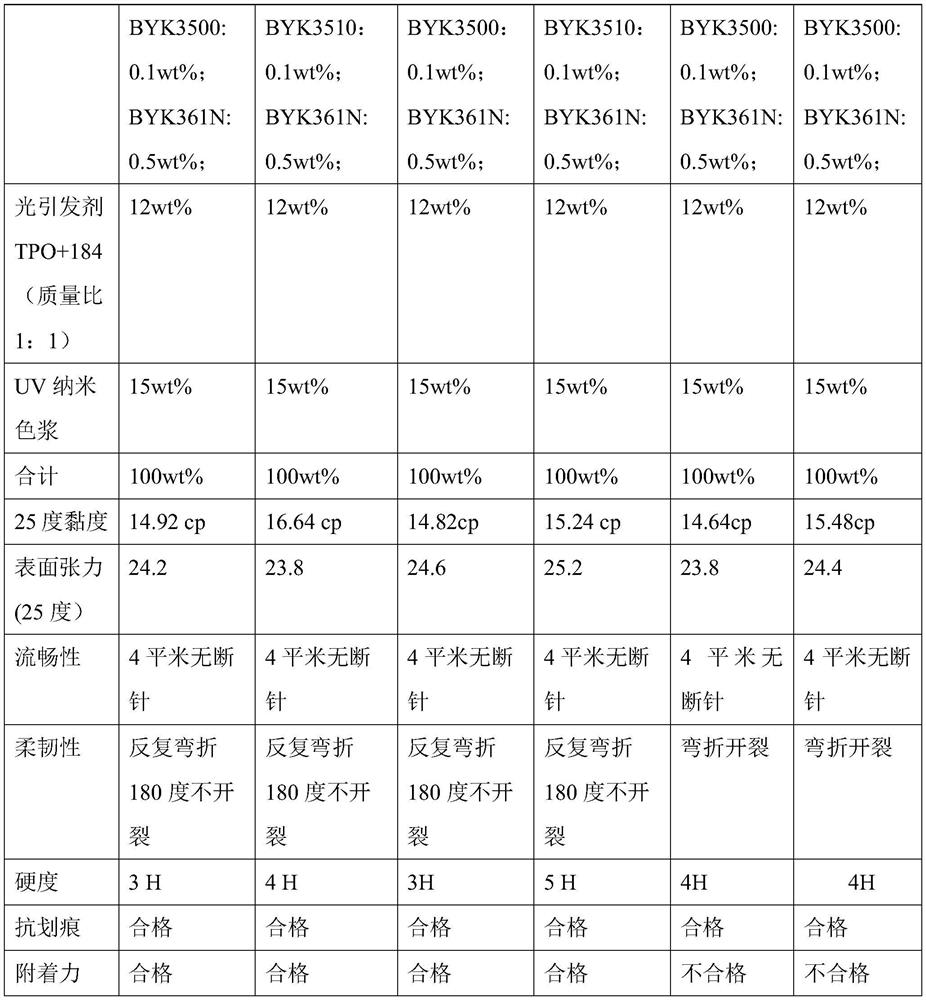

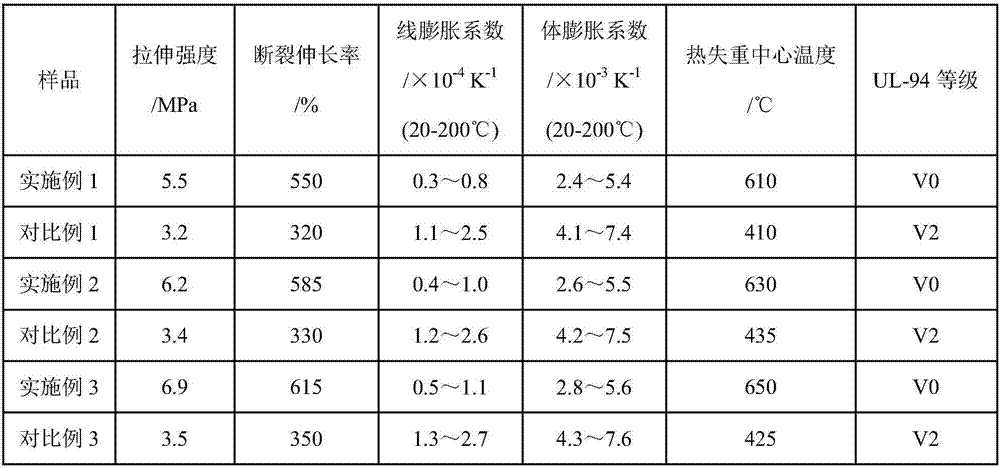

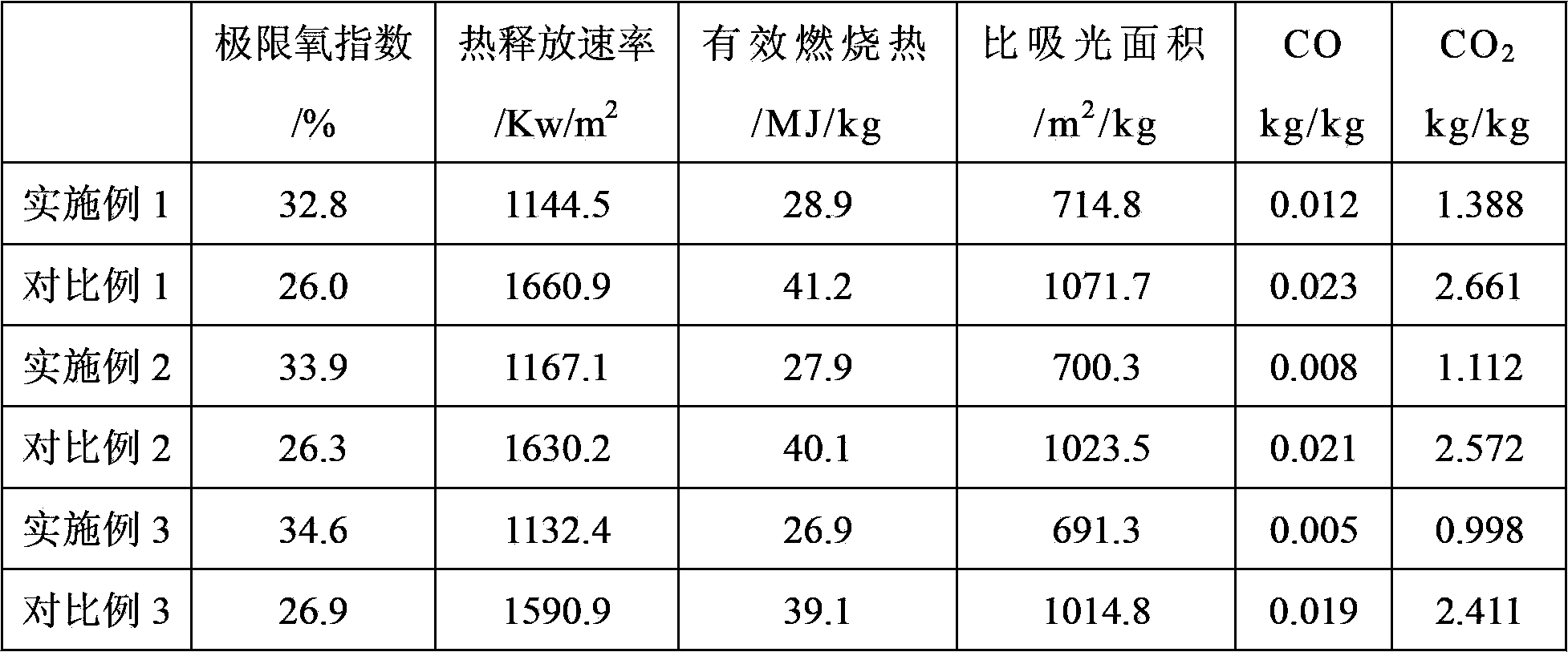

White neutral ink for UV-LED ink-jet printing and preparation method thereof

The invention discloses white neutral ink for UV-LED ink-jet printing and a preparation method thereof. The white neutral ink for UV-LED ink-jet printing is prepared from the following components and a formula: 2 to 15 weight percent of resin, 55 to 70 weight percent of a diluting monomer A, 10 to 25 weight percent of UV nano color paste, 5 to 15 weight percent of a photoinitiator and 0.1 to 5 weight percent of an auxiliary agent, wherein the sum of the percentages of the components is 100 percent; at least one of the resin, the diluting monomer A and the UV nano color paste has an amide group. The white neutral ink is green, environment-friendly, good in adhesive force and wide in substrate application range, can be applied to substrates such as soft materials such as leather and TPU and hard materials such as PC, ABS and PMMA, does not crack after being repeatedly bent, is adjustable in hardness, has both flexibility and hardness, also has the excellent characteristics of good smoothness, low viscosity, scratch resistance, high covering degree and the like, and is excellent in comprehensive performance.

Owner:浙江老虎印新材料科技有限公司

Flame-retardant supermolecular silicone rubber and preparation method thereof

The invention discloses flame-retardant supermolecular silicone rubber and a preparation method thereof. The flame-retardant supermolecular silicone rubber is prepared from components in parts by mass as follows: 90-95 parts of a component I, 5-10 parts of a component II, 0.3-0.5 parts of a catalyst and 5-15 parts of supermolecular glass fiber through mixing and curing, wherein the component I is polysiloxane containing vinyl end groups, the component II is hydrogen-containing polysiloxane, and the supermolecular glass fiber is obtained by wrapping glass fiber with multiple layers of supermolecular films formed by self-assembling diphosphonate and ferrous chloride on the basis of coordination bonds. The supermolecular glass fiber is added to silicone rubber, so that the prepared silicone rubber has high flame retardance, mechanical property, dimensional stability and heat stability, and the use range of the silicone rubber is broadened; besides, the preparation technology is economical and practical, the preparation process is simple, the cost is low and large-scale production is easily realized.

Owner:东莞市诚印有机硅科技有限公司

Hot vulcanization type flame-retardant silicon rubber composite material and preparation method of hot vulcanization type flame-retardant silicon rubber composite material

ActiveCN102850806BImprove flame retardant performanceHigh smoke suppression effectBoron compoundsPolymer scienceHydrotalcite

The invention discloses a hot vulcanization type flame-retardant silicon rubber composite material and a preparation method of the composite material. The composite material is obtained from hot vulcanization type silicon rubber raw rubber and hydrotalcite-like compounds containing zinc, boron and iron through mixed smelting and vulcanization. The preparation method of the material comprises the following preparation steps that firstly, the hot vulcanization type silicon rubber raw rubber and the hydrotalcite-like compounds containing zinc, boron and iron in the proportioning quantity are subjected to uniform mixed smelting; then, vulcanizing agents are added, and sheet discharge is carried out after the uniform mixed smelting; and finally, the vulcanization is carried out. The hot vulcanization type flame-retardant silicon rubber composite material provided by the invention has obvious flame-retardant and smoke suppression performances, and in addition, the physical mechanical performance is excellent. In addition, the preparation process of the composite material is economic and practical, the controllability is high, the cost is low, the large-scale production is easily realized, and the practicability is realized.

Owner:浙江沪天胶带有限公司

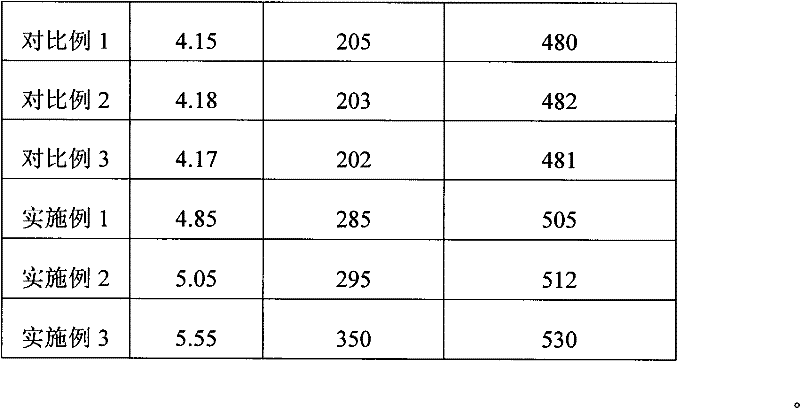

Montmorillonite-modified silicon rubber nanocomposite and preparation method thereof

The invention discloses a montmorillonite-modified silicon rubber nanocomposite and a preparation method thereof. The montmorillonite-modified silicon rubber nanocomposite comprises the following components in parts by weight: 90-92 parts of component A, 8-10 parts of component B, 0.1-0.3 part of catalyst and 1-3 parts of organic montmorillonite, wherein the component A is crude ethenyl (or isoallyl)-containing terminated silicon rubber; the component B is hydrogen-containing polysiloxane; the catalyst is chloroplatinic acid or other soluble platinic compound; the organic montmorillonite is hyperbranched quaternary ammonium salt modified organic montmorillonite; and the montmorillonite is taken as a reinforcing material of silicon rubber. The prepared silicon rubber nanocomposite has the advantages of: (1) higher mechanical property and heat resistance, (2) higher processability, (3) more economical and practical preparation technology; and the characteristics play an important role in making the silicon rubber / organic montmorillonite nanocompoiste practical.

Owner:SHANGHAI UNIV OF ENG SCI

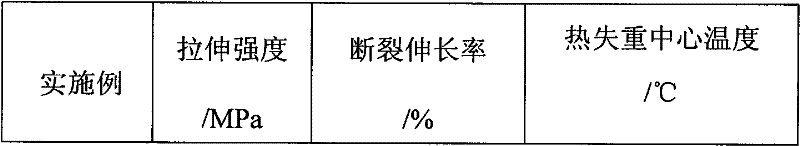

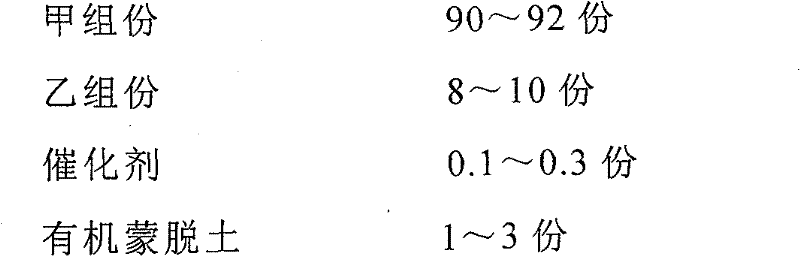

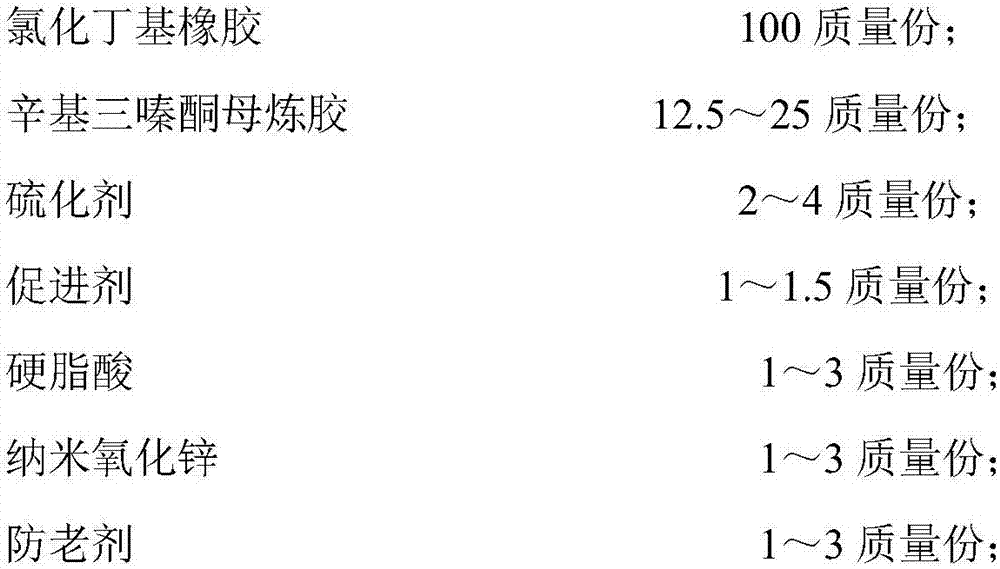

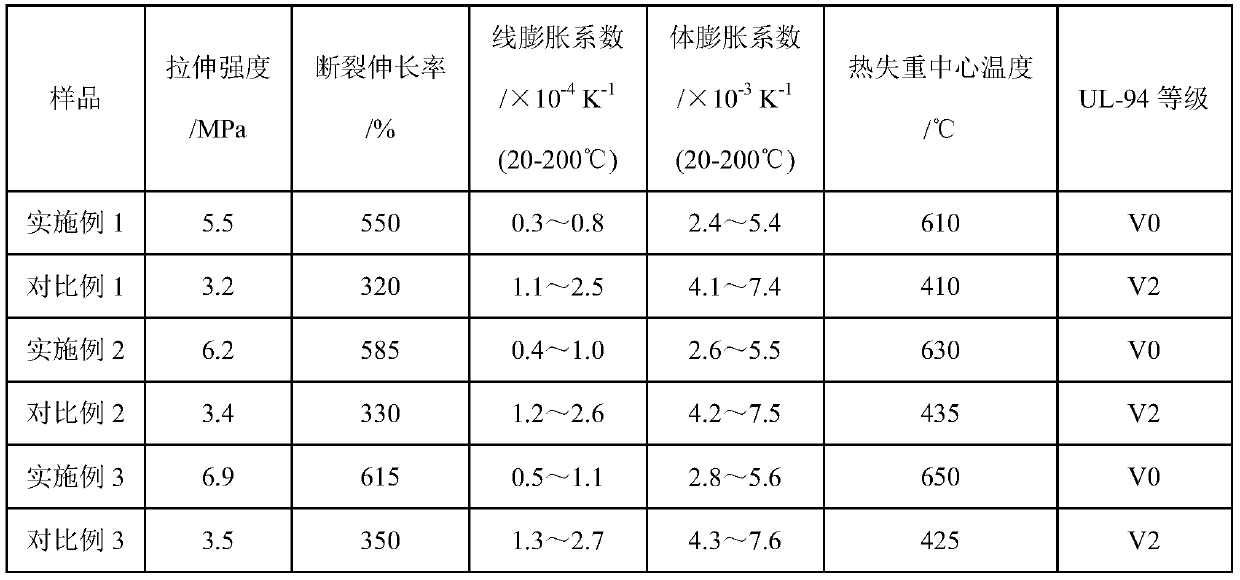

A kind of high damping chlorobutyl damping rubber and preparation method thereof

ActiveCN105906956BImprove damping performanceImprove mechanical propertiesEthylhexyl triazonePolymer science

The invention discloses high-damping chlorinated butyl rubber and a method for preparing the same. The high-damping chlorinated butyl rubber comprises, by weight, 100 parts of chlorinated butyl rubber, 12.5-25 parts of ethylhexyl triazone rubber master batch, 2-4 parts of vulcanizing agents, 1-1.5 parts of accelerators, 1-3 parts of stearic acid, 1-3 parts of nanometer zinc oxide and 1-3 parts of anti-aging agents. The chlorinated butyl rubber, the ethylhexyl triazone rubber master batch, the vulcanizing agents, the accelerators, the stearic acid, the nanometer zinc oxide and the anti-aging agents are mixed with one another to obtain the high-damping chlorinated butyl rubber. As proved by experiments, the high-damping chlorinated butyl rubber and the method have the advantages that the chlorinated butyl rubber is modified by the aid of the ethylhexyl triazone rubber master batch, and accordingly chlorinated butyl rubber materials which are excellent in damping property and mechanical property and wide in damping temperature range can be obtained; processes for preparing the high-damping chlorinated butyl rubber are economical and practical and are easy to implement and low in cost, and scale production can be facilitated.

Owner:SHANGHAI UNIV OF ENG SCI

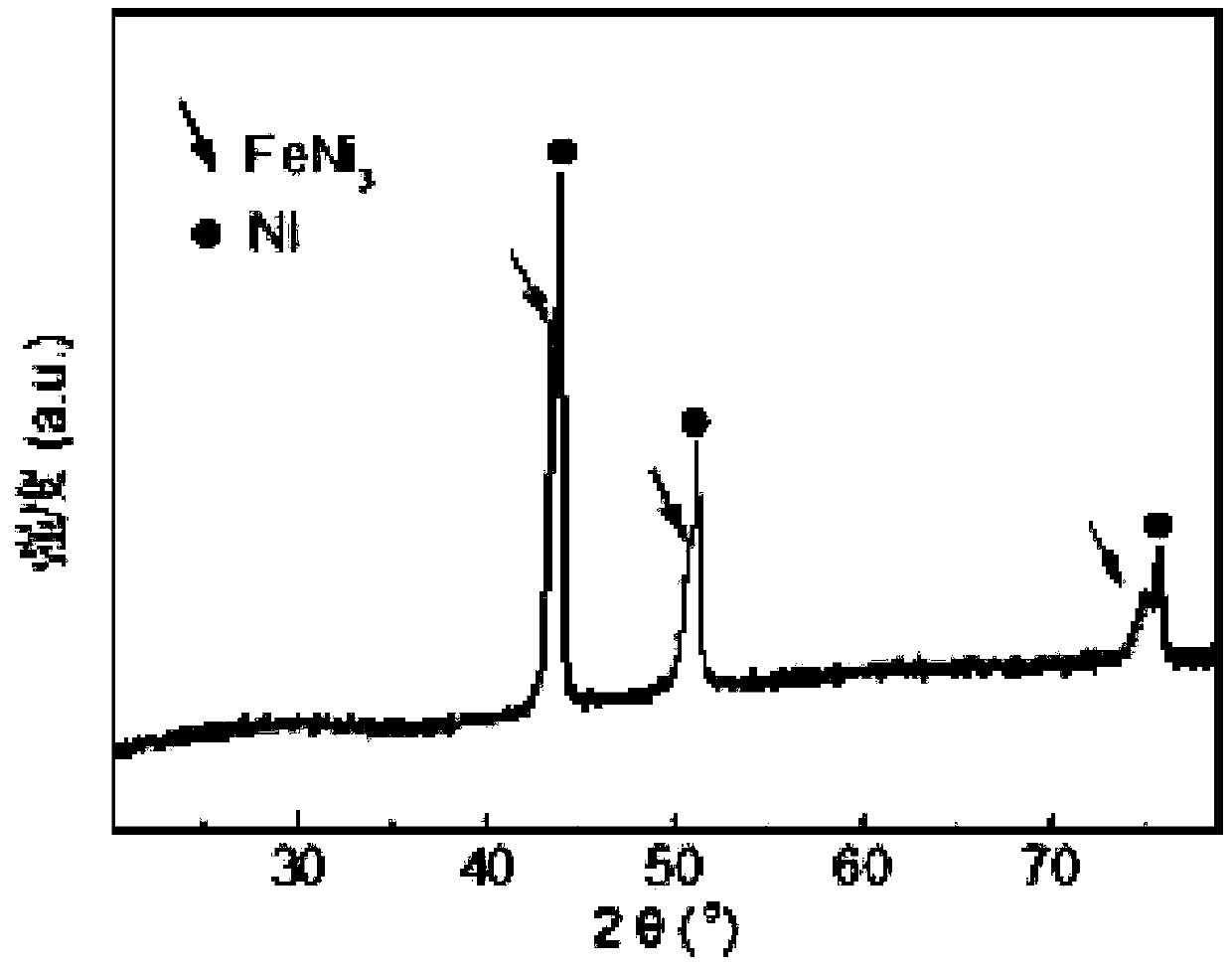

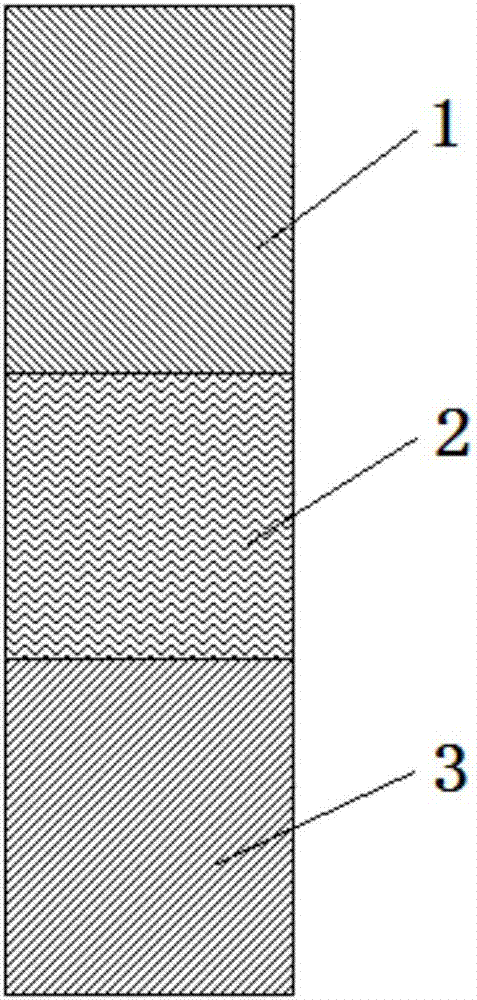

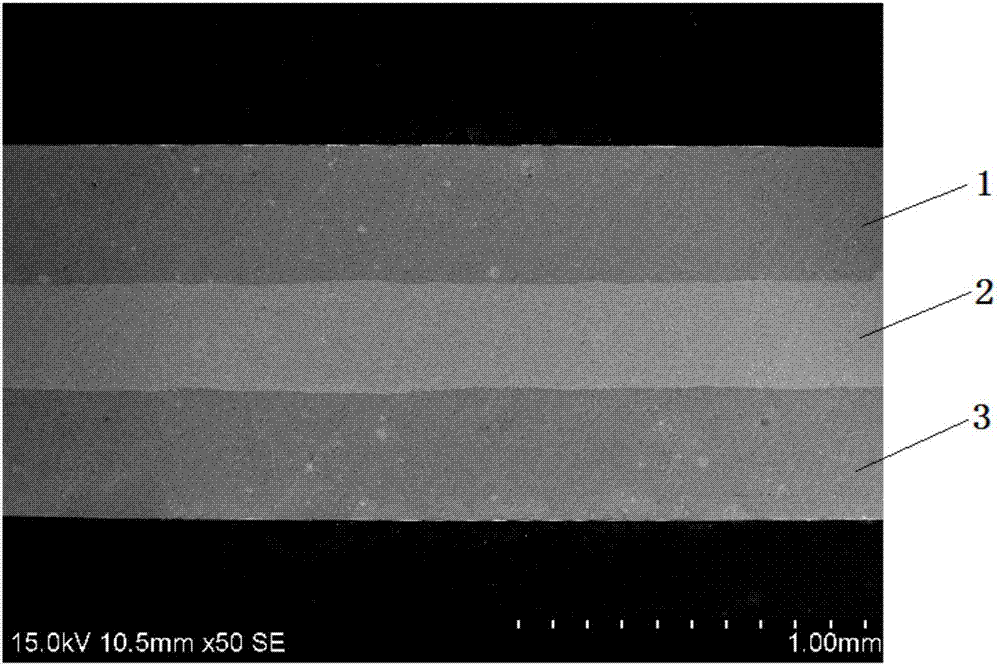

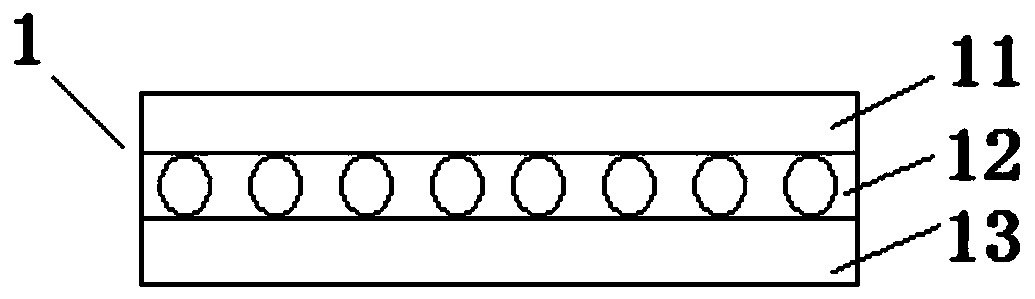

Thermal bimetallic material taking electrical pure iron as middle layer and preparation method of thermal bimetallic material

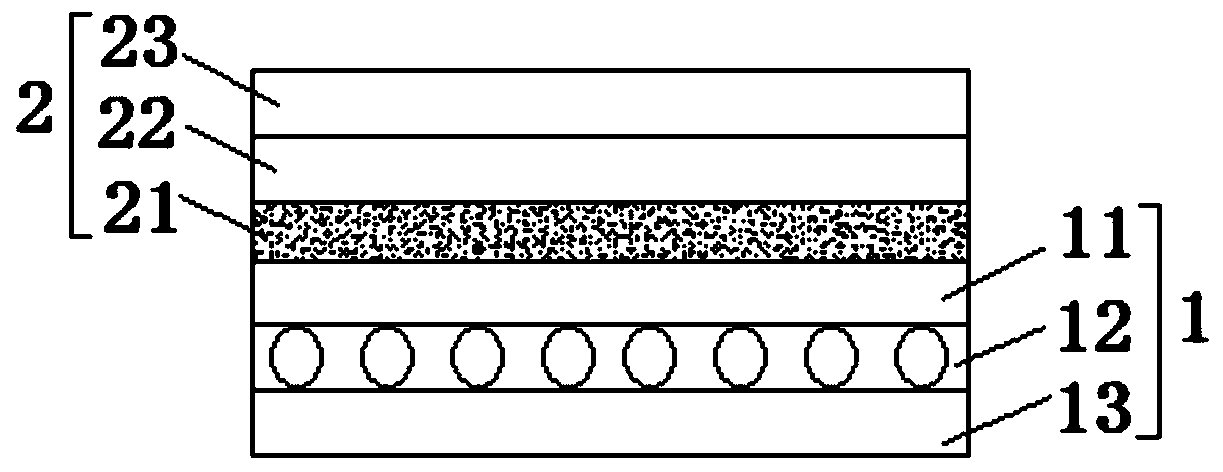

InactiveCN107225822AMeet application requirementsReduce manufacturing costLamination ancillary operationsLaminationUltimate tensile strengthActive layer

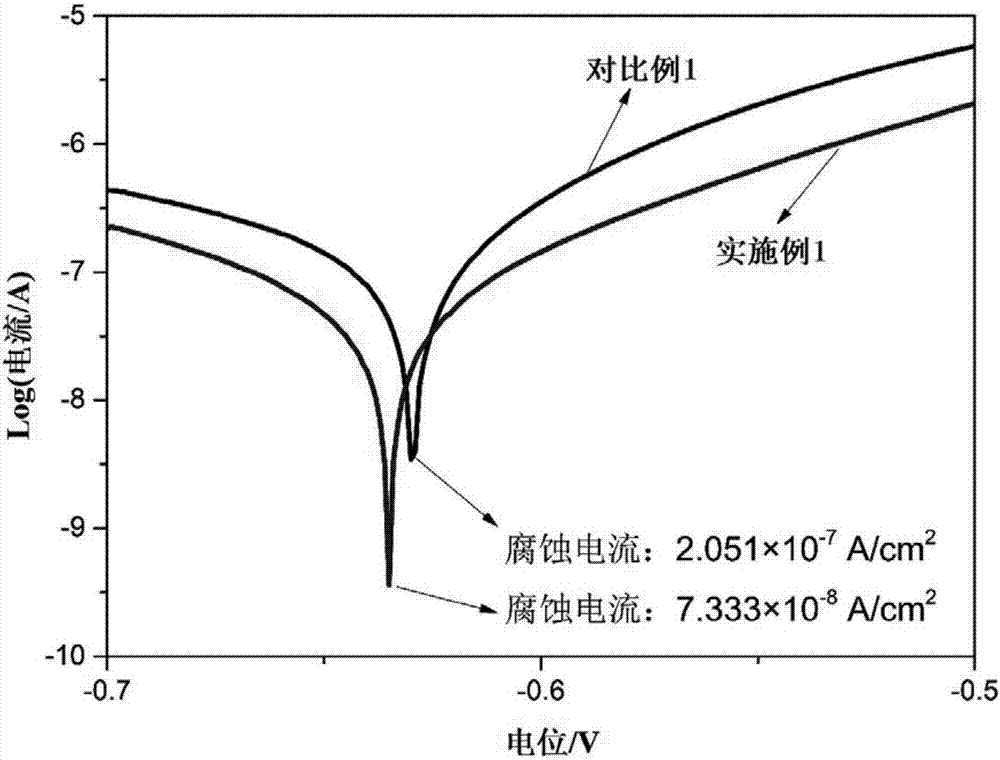

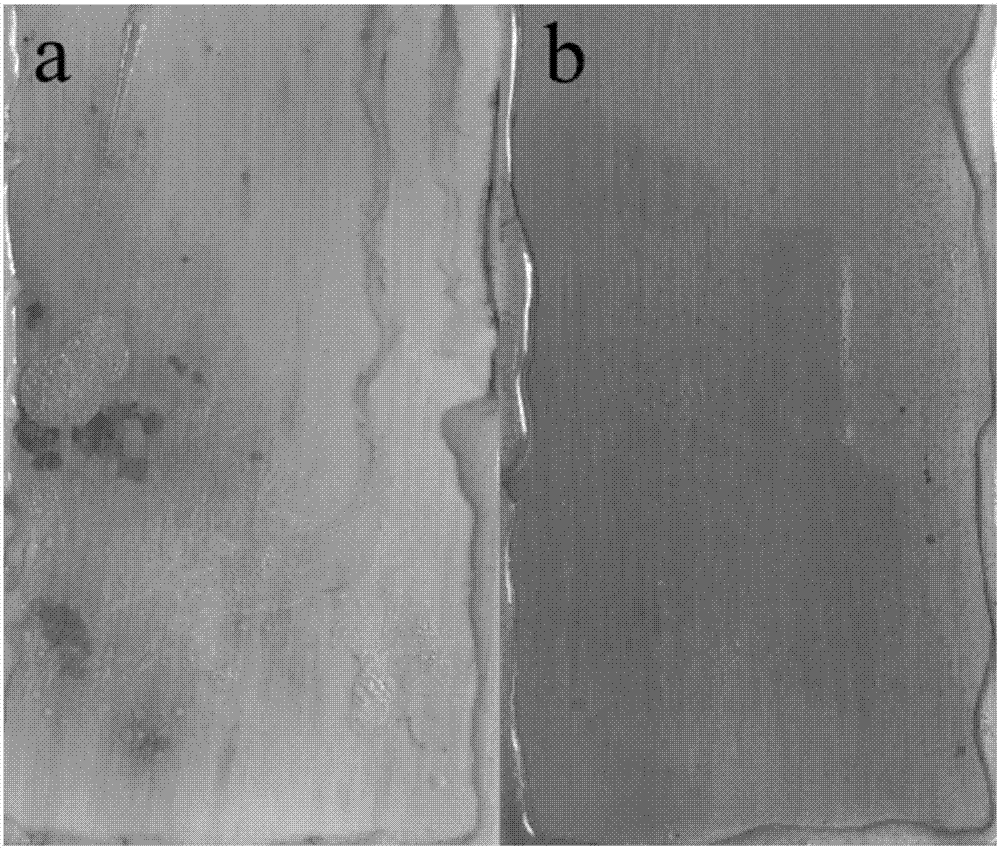

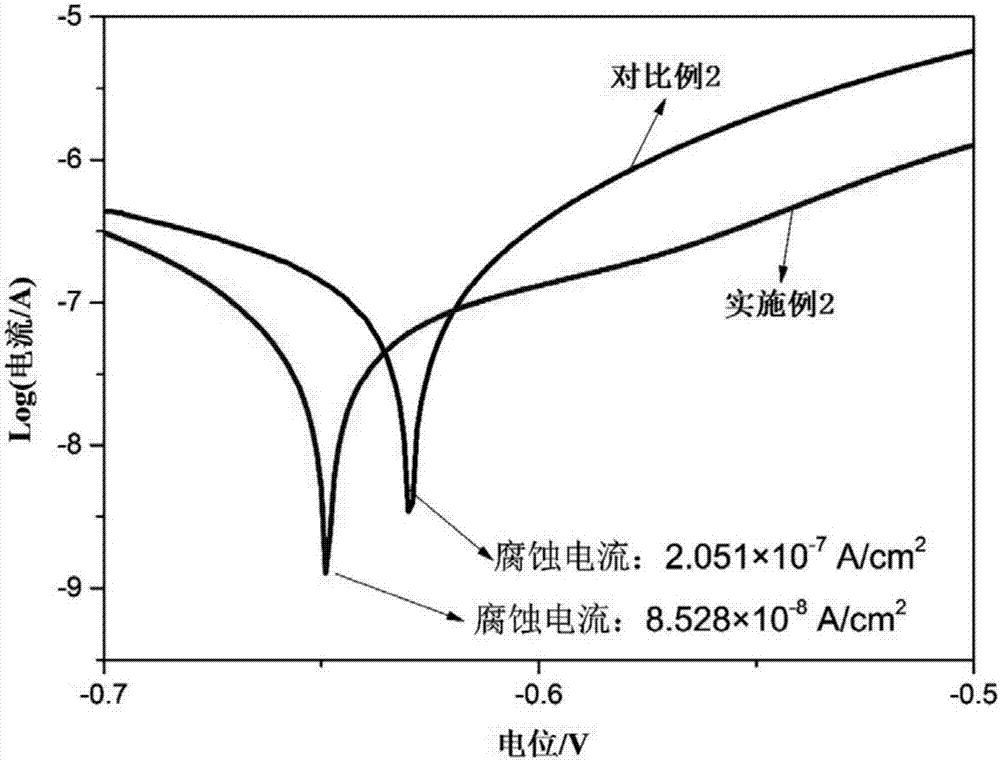

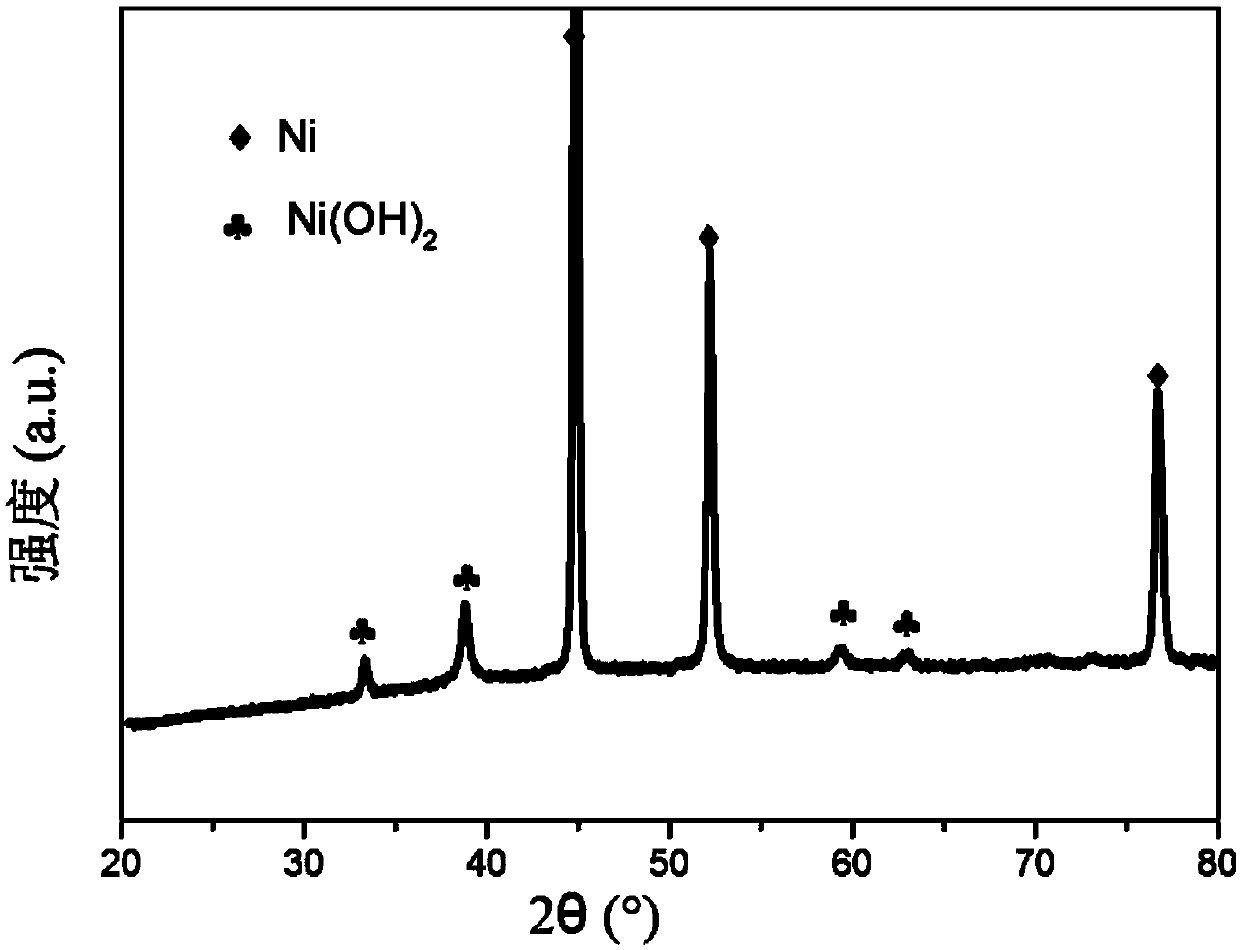

The invention discloses a thermal bimetallic material taking electrical pure iron as a middle layer and a preparation method of the thermal bimetallic material. The thermal bimetallic material is of a layered structure and comprises an active layer, a passive layer and the middle layer sandwiched between the active layer and the passive layer, wherein the active layer is made from iron-nickel-chromium FeNi22Cr3, the middle layer is made from the electrical pure iron, and the passive layer is made from ferronickel FeNi36. The thermal bimetallic material disclosed by the invention has good flexivity, resistivity, welding performance and corrosion resistance, and perfect balance between low cost and corrosion resistance is achieved; in addition, by the preparation method disclosed by the invention, the bonding strength among the layers of the prepared thermal bimetallic material can be relatively high, and bonded interfaces can be flat and straight and be free of cracking phenomena.

Owner:上海松森特殊金属有限公司 +1

A kind of supramolecular flame-retardant silicone rubber and preparation method thereof

ActiveCN106854370BImprove flame retardant performanceImprove reinforcement effectFiberPolymer science

The invention discloses flame-retardant supermolecular silicone rubber and a preparation method thereof. The flame-retardant supermolecular silicone rubber is prepared from components in parts by mass as follows: 90-95 parts of a component I, 5-10 parts of a component II, 0.3-0.5 parts of a catalyst and 5-15 parts of supermolecular glass fiber through mixing and curing, wherein the component I is polysiloxane containing vinyl end groups, the component II is hydrogen-containing polysiloxane, and the supermolecular glass fiber is obtained by wrapping glass fiber with multiple layers of supermolecular films formed by self-assembling diphosphonate and ferrous chloride on the basis of coordination bonds. The supermolecular glass fiber is added to silicone rubber, so that the prepared silicone rubber has high flame retardance, mechanical property, dimensional stability and heat stability, and the use range of the silicone rubber is broadened; besides, the preparation technology is economical and practical, the preparation process is simple, the cost is low and large-scale production is easily realized.

Owner:东莞市诚印有机硅科技有限公司

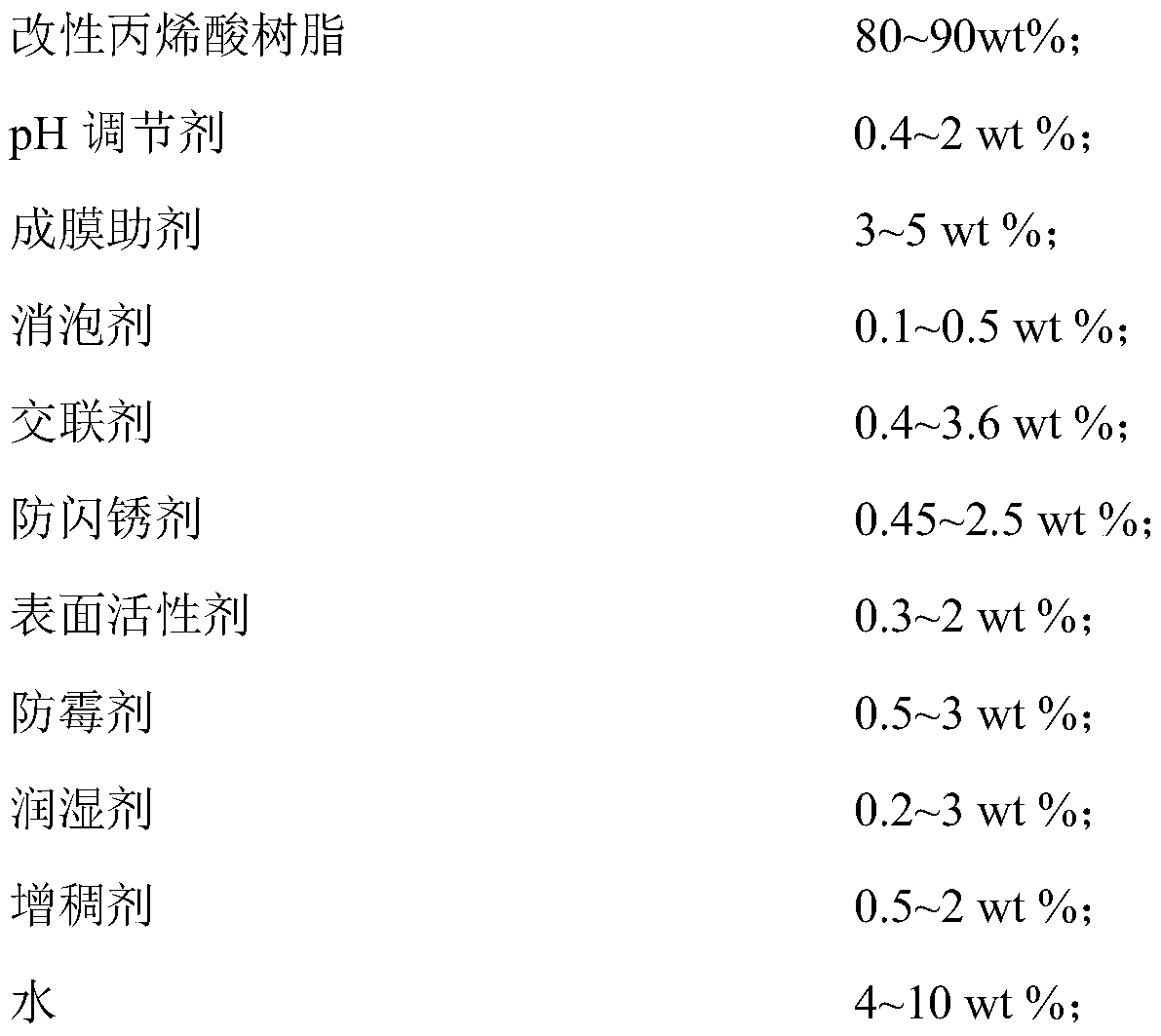

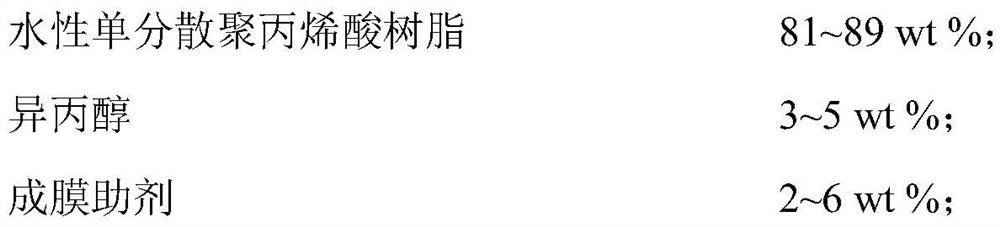

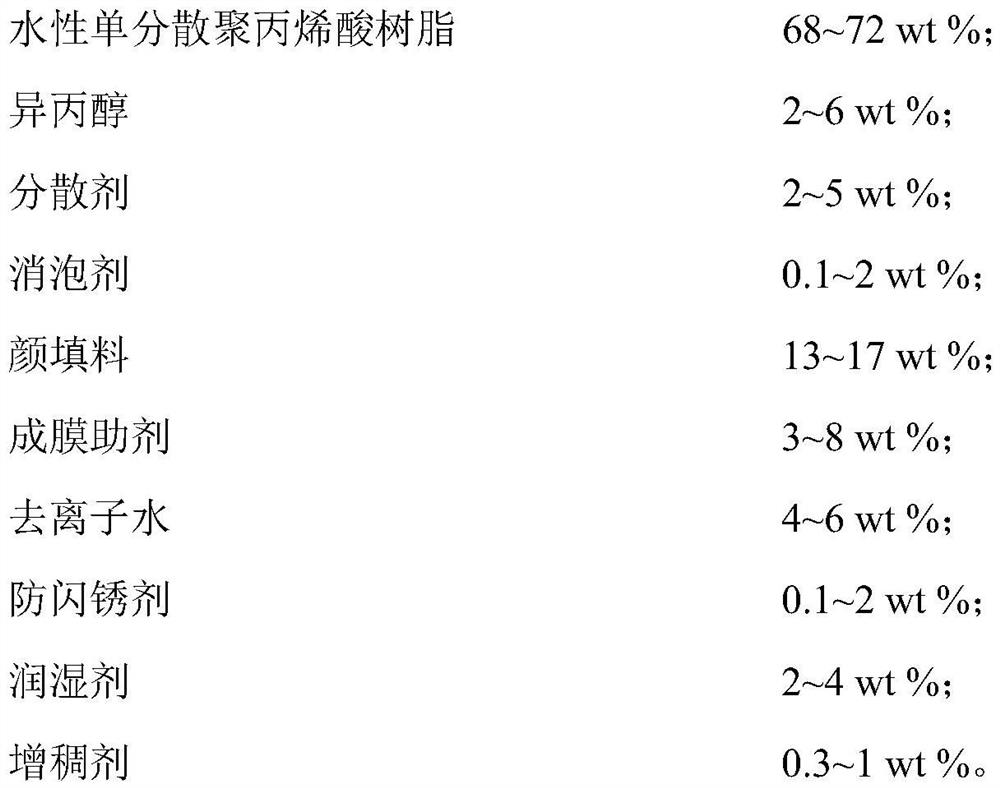

A kind of water-based quick-drying coil coating based on monodisperse polyacrylic acid resin and preparation method thereof

ActiveCN110358400BGood dispersionNo pollution in the processAnti-corrosive paintsSolvent freeALLYL SUCROSE

The invention discloses a water-based quick-drying coil coating based on monodisperse polyacrylic acid resin and a preparation method thereof. The water-based quick-drying coil coating includes varnish and / or color paint, and the varnish includes water-based monodisperse polyacrylic resin, isopropanol, film-forming aid, defoamer, deionized water, anti-flash rust agent, wetting agent Wetting agent, thickener; the color paint includes water-based monodisperse polyacrylic resin, isopropanol, dispersant, defoamer, pigment and filler, anti-flash rust agent, film-forming aid, deionized water, wetting agent , Thickener. The coating of the present invention is not only environmentally friendly and free from solvent pollution, but also has good dispersibility, good film-forming property and high gloss, and has excellent properties such as alkali resistance, corrosion resistance and water resistance, especially excellent fast Dry performance, adhesion, flexibility and hardness have reached a balance between hardness and flexibility, and the comprehensive performance is excellent, suitable for coiled steel.

Owner:SHANGHAI UNIV OF ENG SCI

A kind of organic-inorganic water-based quick-drying coating and its preparation method and film-forming method

The invention discloses an organic-inorganic water-based quick-drying coating, a preparation method and a film-forming method thereof. The organic-inorganic water-based quick-drying coating has the following composition and proportion: coupling agent A: 16.5-23.5wt%; coupling agent B: 16.5-23.5wt%; nano aluminum sol: 15.5-23.5wt%; : 17.5~23.5wt%; Anti-settling agent: 0.2~2wt%; Wetting and dispersing agent: 0.5~2.5wt%; Anti-sticking agent: 0.5~2wt%; Leveling agent: 0.5~2wt%; ~19 wt%. The coating of the present invention is green and environmentally friendly, and can be formed into a film in about one minute in the mixed drying method of high temperature baking at 120-140°C + electromagnetic heating with a power of 90-150w, and can also maintain a good appearance and anti-corrosion ability. Used as a baking coating.

Owner:SHANGHAI UNIV OF ENG SCI +1

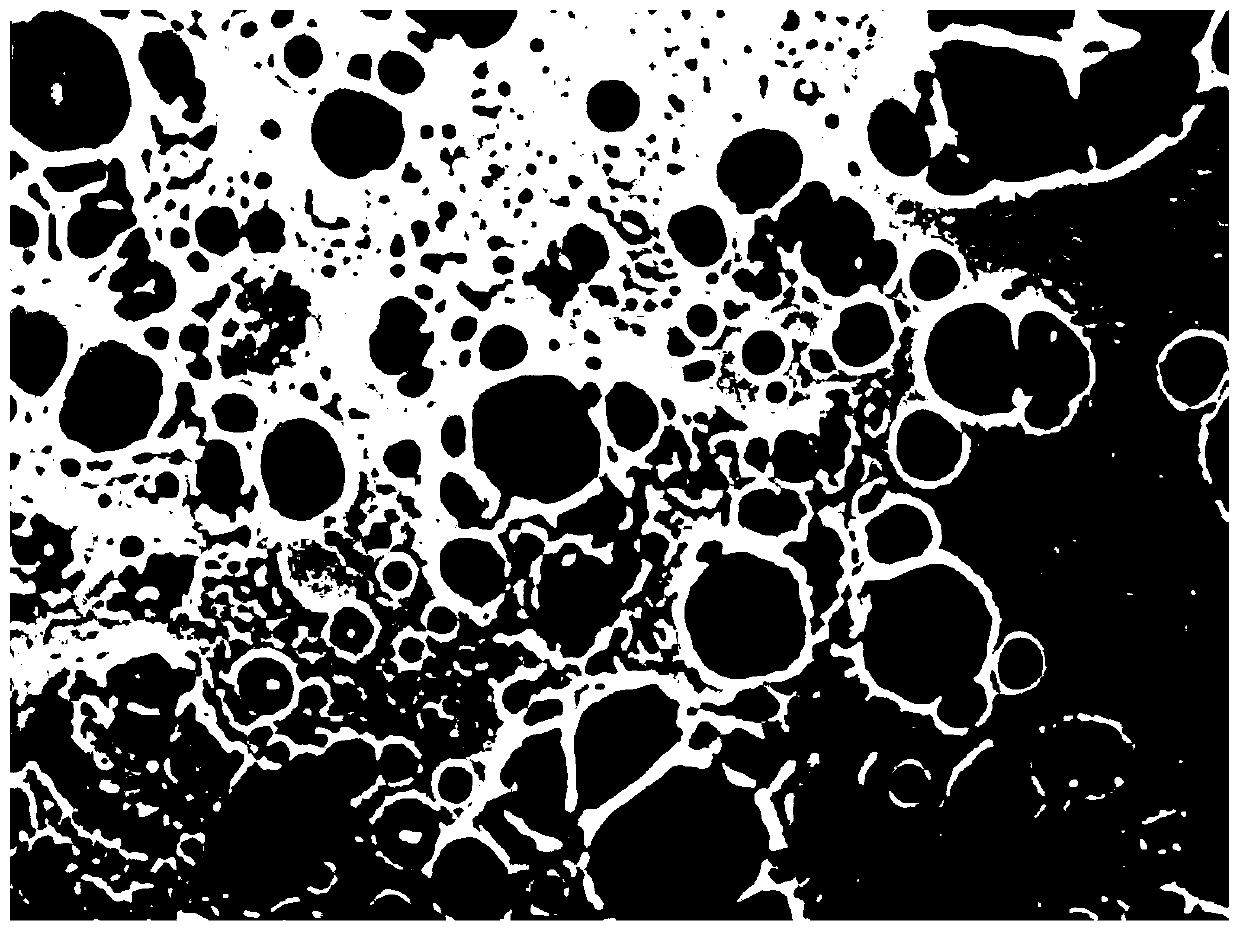

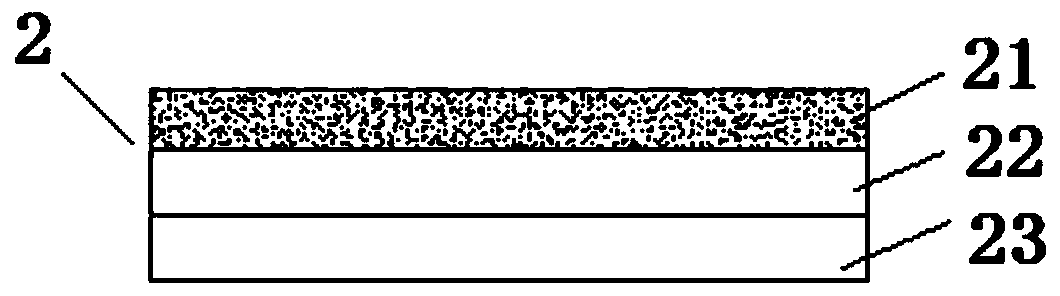

Film for pressure sensing test and preparation method thereof

ActiveCN108398199BTo achieve the purpose of stress testingLow costForce measurementFluid pressure measurementMicrospherePhotopigment

The invention discloses a film for a pressure sensing test and a preparation method of the film. The film for the pressure sensing test is a two-sheet type film and includes a film A and a film B; a pressure-sensitive adhesive layer and a deformable microsphere coating sequentially coat a substrate A from bottom to top, so that the film A can be formed; a first pigment coating layer and a second pigment coating layer sequentially coat a substrate B from bottom to top, so that the film B can be formed; and during the pressure test, the pressure-sensitive adhesive layer of the film A is attachedto the front surface of the first pigment layer of the film B. The film for the pressure sensing test of the invention has the advantages of low cost, convenient use, simple preparation process and no pollution to the environment, and can replace a traditional chemical color developing film so as to be applied to the pressure test.

Owner:上海净极防护用品有限公司

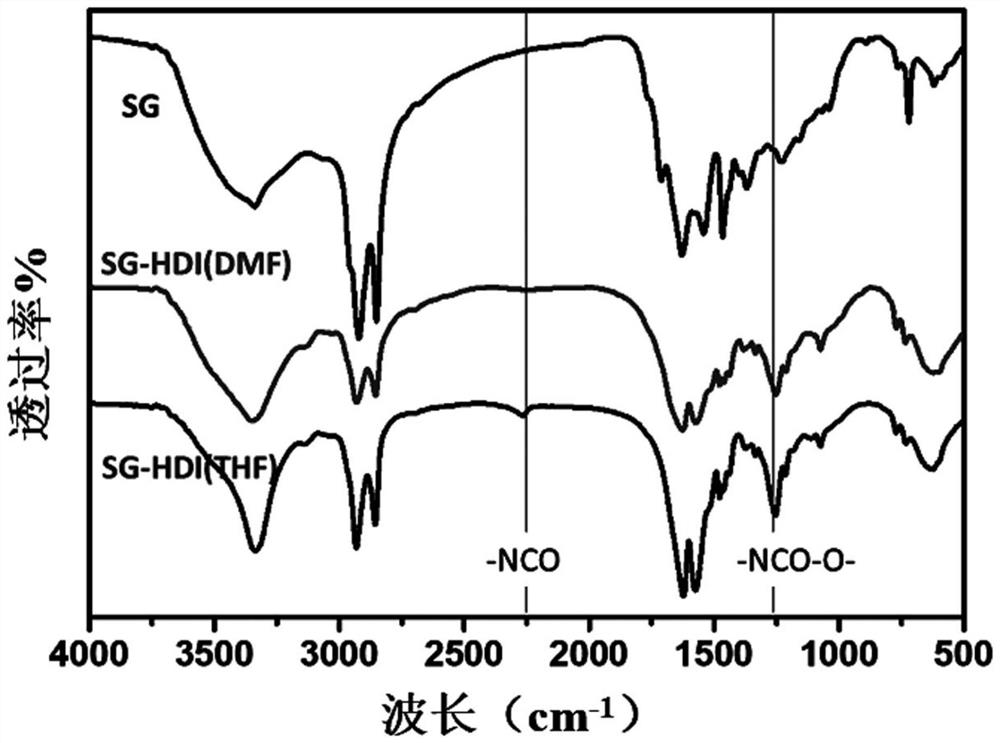

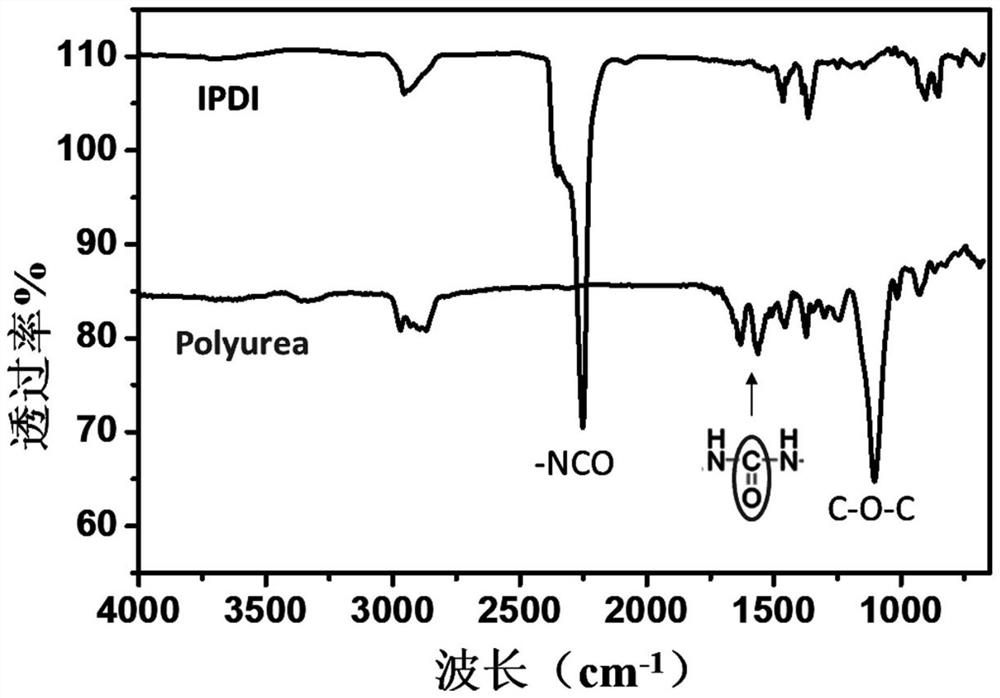

A kind of modified graphene waterborne polyurea resin and its preparation method and application

ActiveCN111171276BGood dispersionImprove stabilityPolyurea/polyurethane coatingsPolymer scienceOrganic solvent

The invention discloses a modified graphene waterborne polyurea resin as well as a preparation method and application thereof. The modified graphene water-based polyurea resin is made of isocyanate-modified sulfonated graphene in an organic solvent and first reacts with isophorone diisocyanate, then reacts with polyetheramine, and then extends with polyetheramine chain extender. Chain reaction, then react with hydrophilic chain extender, then neutralize with neutralizing agent, finally add deionized water to disperse evenly and remove organic solvent to obtain, the isocyanate modified sulfonated graphene is obtained by isocyanate Modified sulfonated graphene. The water-based polyurea coating prepared by applying the modified graphene water-based polyurea resin of the present invention is environmentally friendly, convenient in construction, good in coating adhesion, not easy to peel off, and has excellent mechanical properties and anti-corrosion properties.

Owner:SHANGHAI UNIV OF ENG SCI

Composite separation membrane based on in situ growth organic framework structure of fluorine-containing copolymer and its preparation method and application

ActiveCN113209836BGood compatibilityAperture size adjustableSemi-permeable membranesDispersed particle separationTetrafluoroethyleneFluoropolymer

The invention discloses a composite separation membrane based on an in-situ grown organic framework structure of a fluorine-containing copolymer, a preparation method and an application thereof. Random copolymerization of a certain proportion of perfluoro-2,2-dimethyl-1,3-dioxole (PDD), tetrafluoroethylene (TFE) and amino-terminated olefins can be further modified by reaction fluorine-containing copolymers, mixed with PDD-co-TFE binary copolymers in different proportions, and formed into membranes, through the Schiff base reaction, the covalent organic framework structure sheets are grown in situ on the surface of the membrane substrate, and the functional The group is introduced into the framework structure to form a coordination structure, and a fluorine-containing copolymer composite separation membrane is obtained. The composite separation membrane prepared by the method of the present invention significantly enhances the binding force between the fluorine-containing copolymer layer and the organic framework structure layer through amine bridging, and realizes the adjustable internal pore size through the internal structure modification of the pores of the organic framework structure layer , can efficiently and selectively separate organic gases and inorganic gases (oxygen, carbon dioxide, etc.), and has extremely high practical value.

Owner:ZHEJIANG UNIV +1

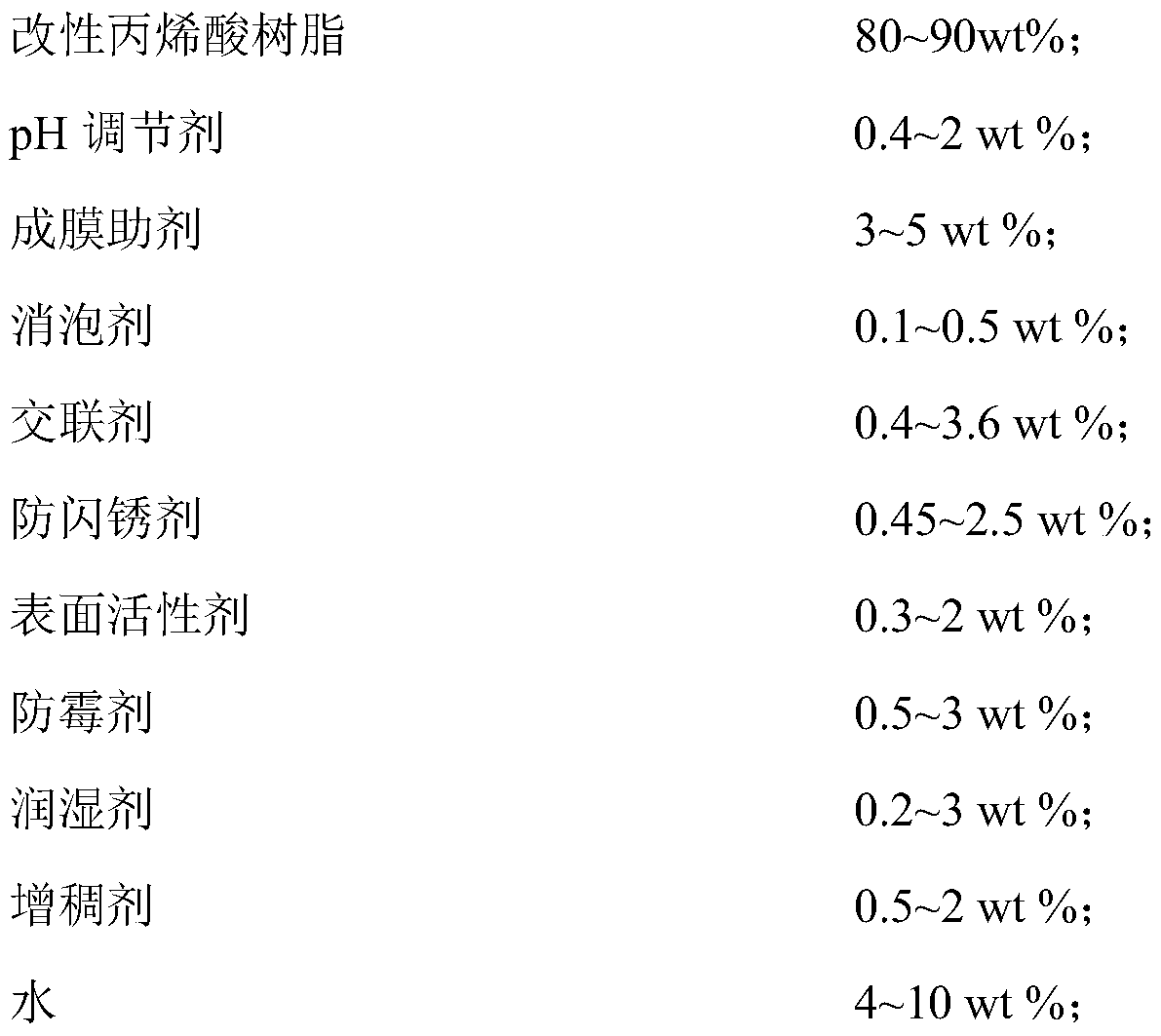

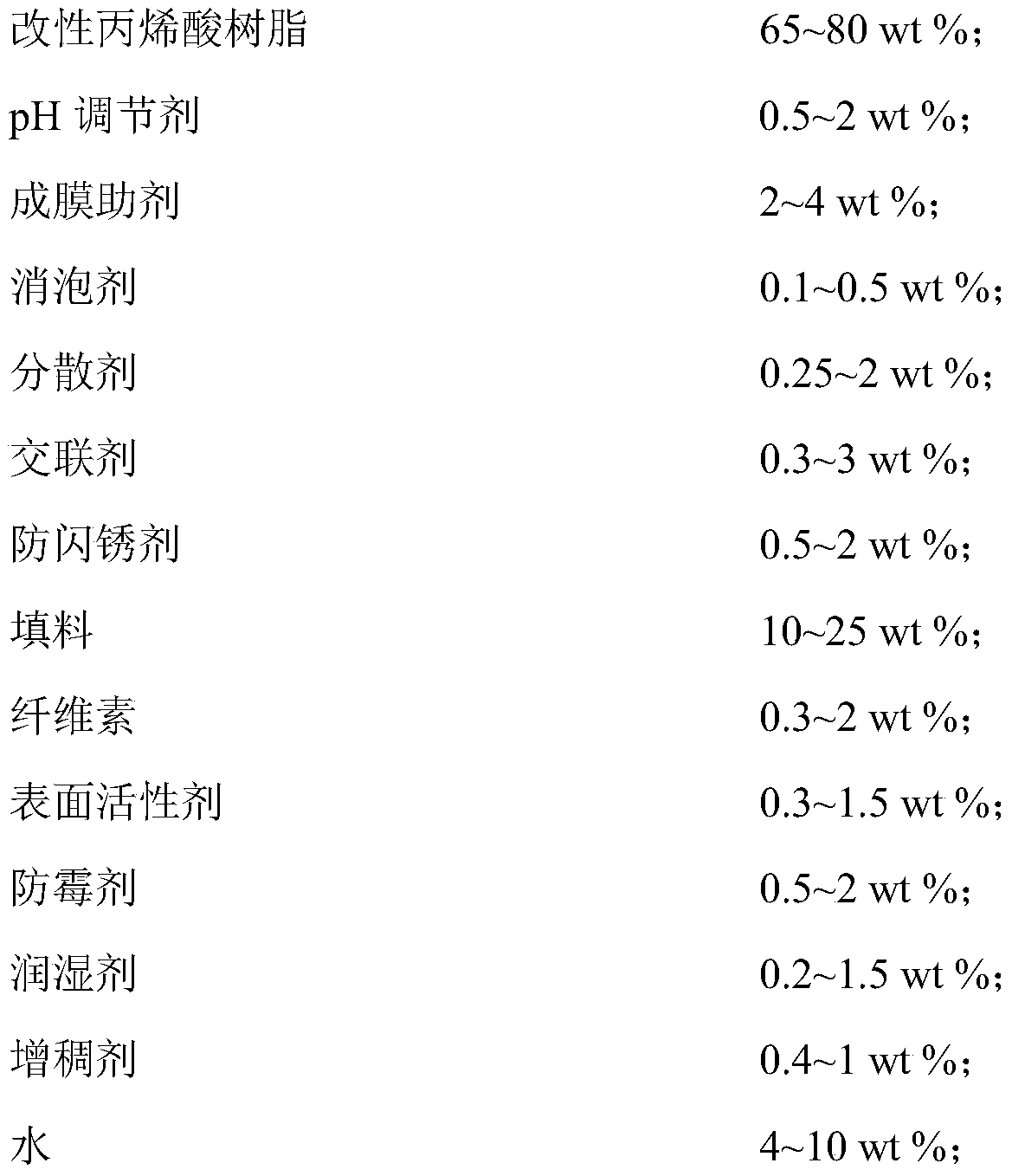

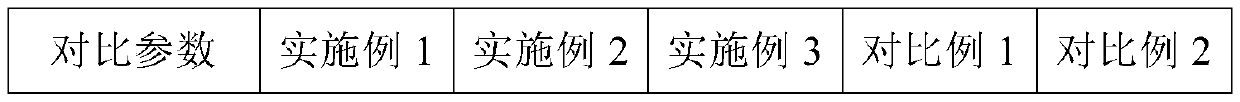

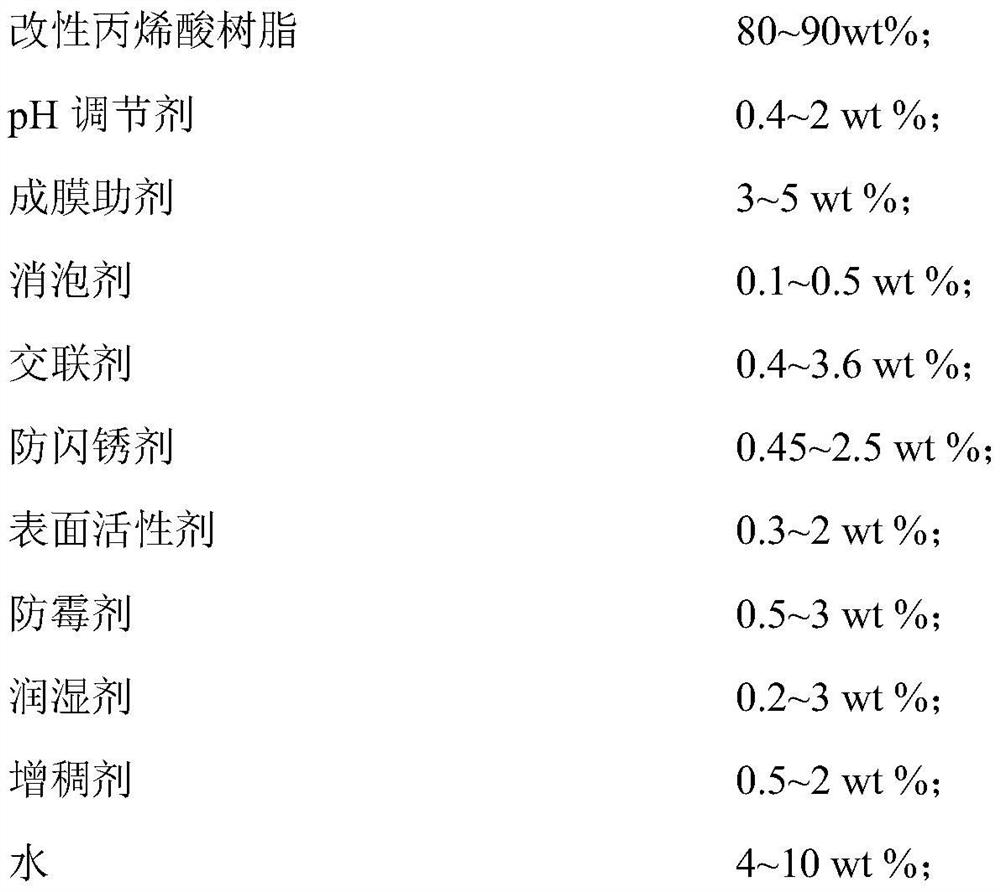

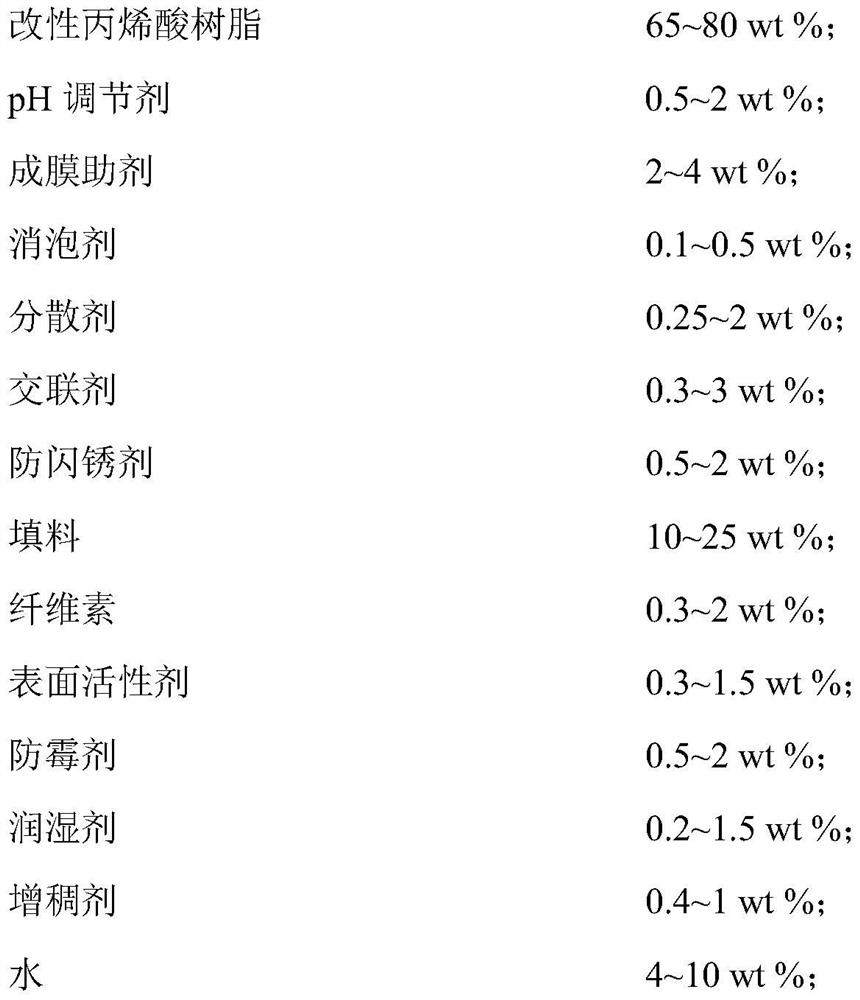

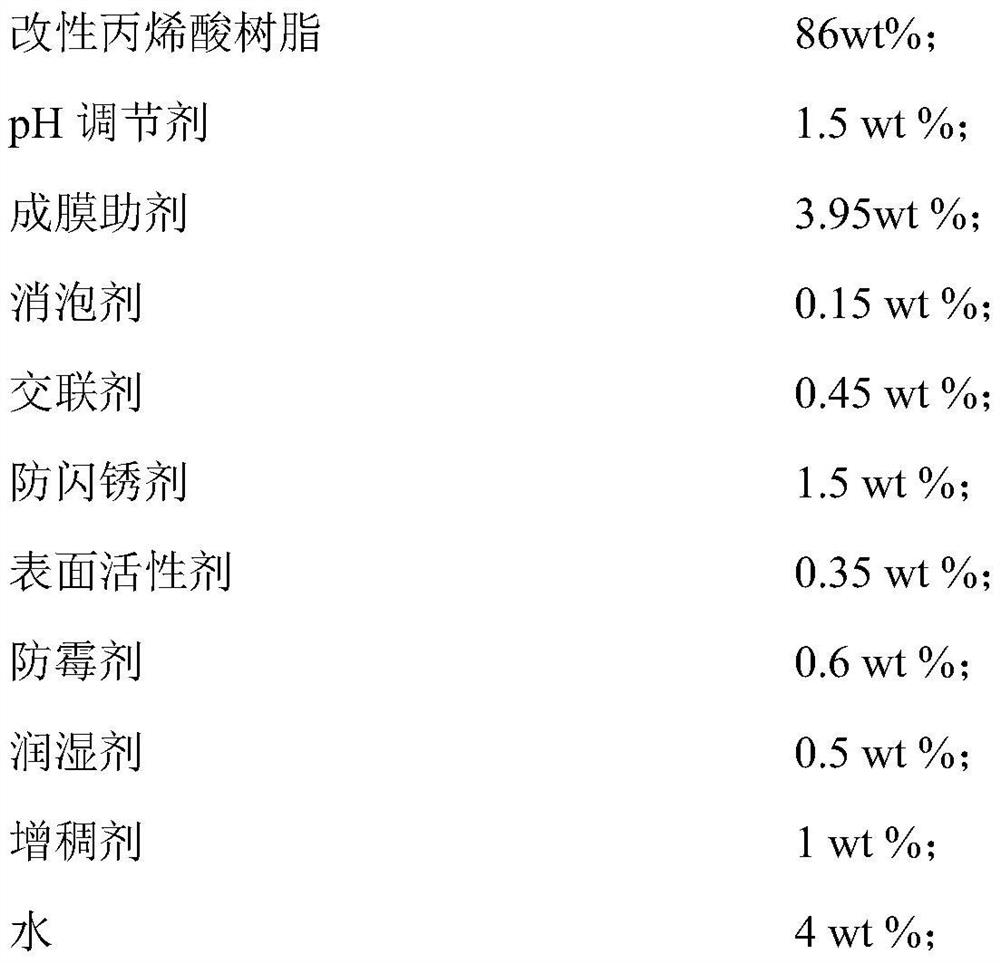

A kind of water-based coil steel repair paint and preparation method thereof

ActiveCN109913072BGood alkali resistanceImprove corrosion resistanceAntifouling/underwater paintsPaints with biocidesAcrylic resinCross linker

The invention discloses water-based coil steel repair paint and a preparation method thereof. The water-based coil steel repair paint comprises a primer and a finish paint, wherein the primer comprises modified acrylic resin, a pH regulator, a film forming additive, a defoaming agent, a crosslinking agent, an anti-flash rust agent, a surfactant, a mildew preventive, a wetting agent, a thickening agent and water; the finish paint comprises modified acrylic resin, a pH regulator, a film forming additive, a defoaming agent, a dispersant, a crosslinking agent, an anti-flash rust agent, filler, cellulose, a surfactant, a mildew preventive, a wetting agent, a thickening agent and water. The water-based coil steel repair paint has excellent water resistance, alkali resistance and quick drying property, thereby having excellent rust-carrying construction capability as a whole; when the paint is used for coil steel repair, all that is required is that a substrate is treated simply to enable thesurface rust-removing grade to reach Sa1 grade, and coating can be performed with conventional methods such as rolling coating and spraying, so that construction is convenient.

Owner:SHANGHAI UNIV OF ENG SCI +1

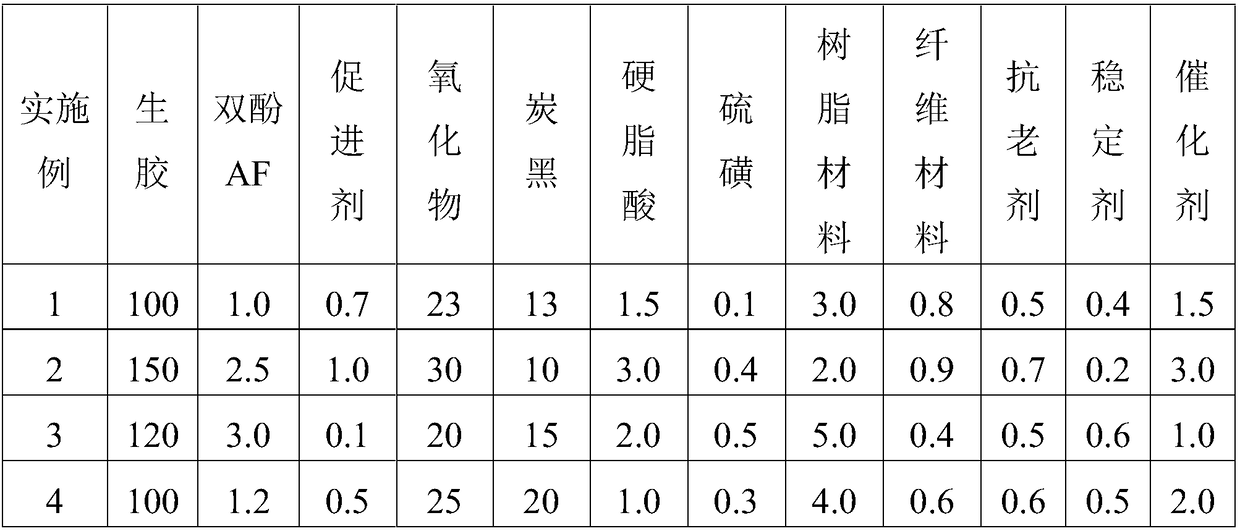

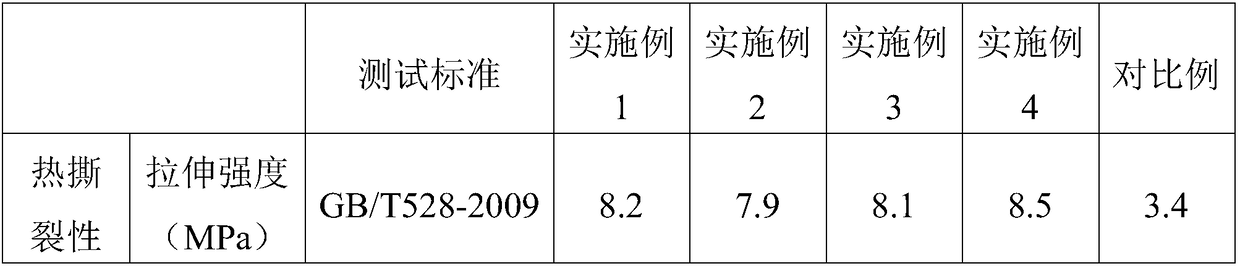

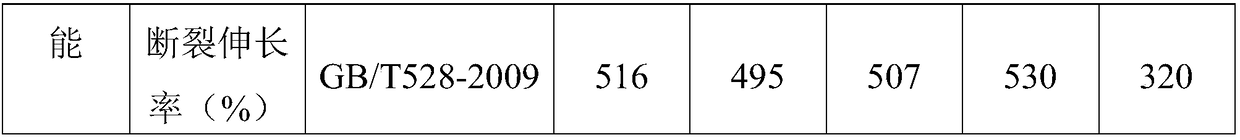

High temperature resistant and thermal tear resistant fluororubber material and preparation technology thereof

InactiveCN109054262AImprove high temperature resistanceSuperior thermal tear resistanceFiberVinyl ether

The invention discloses a high temperature resistant and thermal tear resistant fluororubber material and a preparation method thereof. The high temperature resistant and thermal tear resistant fluororubber material is prepared from the ingredients, in parts by weight: 100-150 parts of raw rubber, 1-3 parts of bisphenol AF, 0.1-1 part of accelerant, 20-30 parts of oxide, 10-20 parts of carbon black, 1-3 parts of stearic acid, 0.1-0.5 part of Sulphur, 2-5 parts of resin material, 0.4-0.9 part of fiber material, 0.5-0.7 part of anti-ageing agent, 0.2-0.6 part of stabilizer and 1-3 parts of catalyst. The raw rubber is prepared from vinylidene fluoride, tetrafluoroethylene, perfluoromethyl vinyl ether and a hexafluoropropylene terpolymer. The resin material is prepared from polyethylene resin,ABS resin and ceramic resin. The fiber material is prepared from spandex fiber, glass fiber and polyester fiber. Through the preparation technology, the selected raw materials and the new processingtechnology can make the prepared fluororubber has the outstanding high temperature resistance and thermal tear resistance, and the yield of vulcanization demolding of fluororubber finished products isimproved.

Owner:勃乐氏密封系统(太仓)有限公司

A kind of water-based coating containing graphene/zinc-aluminum hydrotalcite nanocomposite and preparation method thereof

InactiveCN106995643BImprove compatibilitySolve reunionFireproof paintsAnti-corrosive paintsWater basedNanocomposite

The invention discloses water-based coating containing a graphene / zinc-aluminum hydrotalcite nano composition and a preparation method thereof. The water-based coating is prepared from the following components in parts by weight: 30 to 50 parts of water-based resin, 25 to 40 parts of water, 0.1 to 0.5 part of dispersing agent, 0.1 to 0.5 part of wetting agent, 0.1 to 0.5 part of defoaming agent, 0.1 to 0.5 part of thickening agent, 0.1 to 0.5 part of film forming aids, 0 to 10 parts of curing agent, 0 to 25 parts of titanium dioxide, 0 to 20 parts of calcium carbonate, and 0.1 to 2.5 parts of graphene / zinc-aluminum hydrotalcite nano composition. The graphene / zinc-aluminum hydrotalcite nano composition is added into the water-based coating, so that the high temperature resistance, the corrosion resistance, the flame retardant property, the weather resistance, the impact resistance, the abrasion resistance, the hardness and the obstruction property of the water-based coating are significantly improved, and the multiple functions of the water-based coating are improved.

Owner:东营聚强新材料有限责任公司

A kind of functional powder coating and preparation method thereof

ActiveCN106916515BImprove impact resistanceImprove wear resistancePowdery paintsEpoxy resin coatingsTemperature resistanceMaterials science

Owner:SHANGHAI UNIV OF ENG SCI

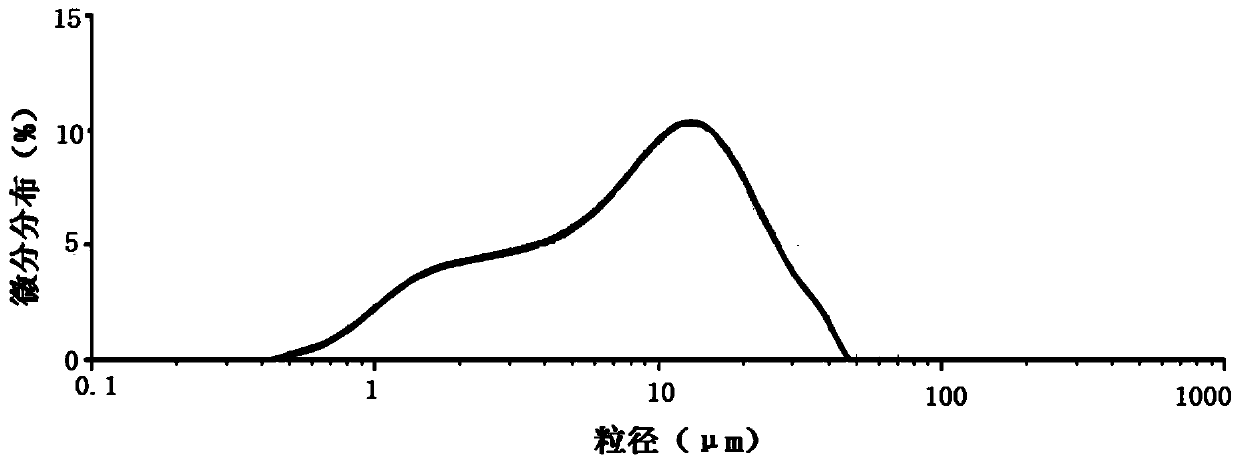

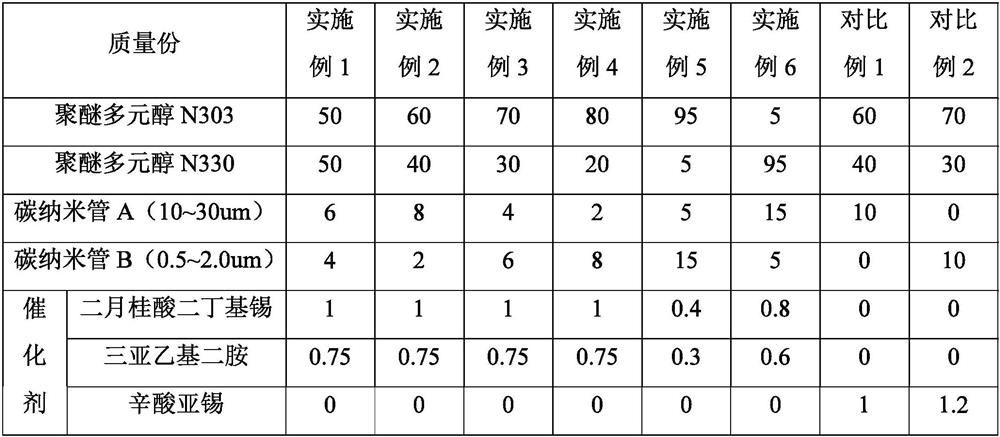

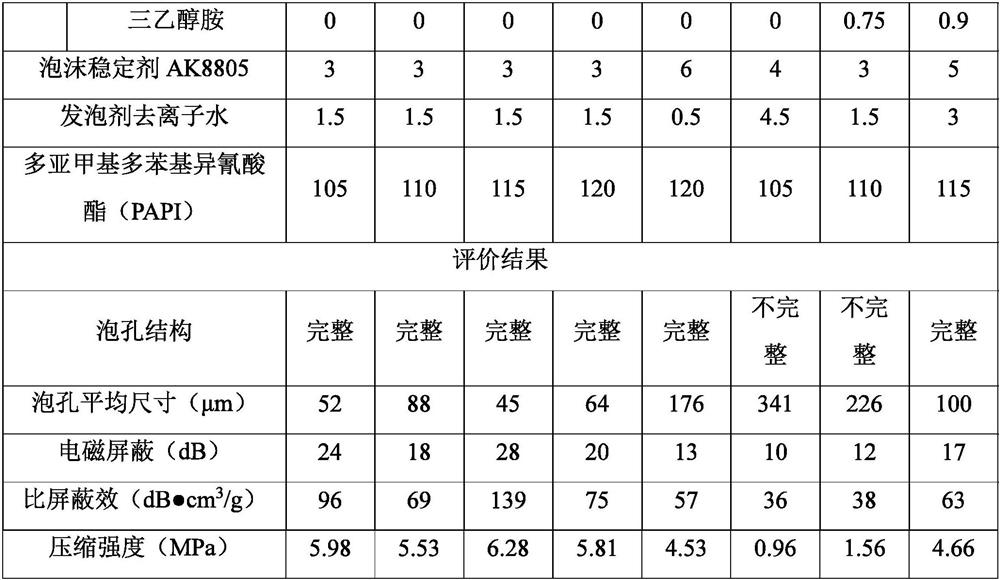

A kind of light-weight high-strength high electromagnetic shielding efficiency material and preparation method thereof

ActiveCN109438650BImprove efficiencyGood dispersionMagnetic/electric field screeningPolymer sciencePtru catalyst

The invention discloses a light-weight, high-strength, high-electromagnetic shielding performance material and a preparation method thereof. The material is formed by mixing and reacting polyether polyol slurry and polyisocyanate. Polyether polyol slurry is composed of mixed polyether polyol, composite carbon nanotubes, catalyst, foam stabilizer and water. Among them, the mixed polyether polyol is formed by mixing one or more polyether polyols in a certain proportion; the composite carbon nanotube is prepared by carbon nanotube A and carbon nanotube B through a preferred ratio, and the carbon nanotube A The length is 10 to 20 times the length of the carbon nanotube B. The method for preparing mixed polyether polyol is S1; the method for preparing polyether polyol slurry is S2; the method for mixing polyether polyol slurry with polyisocyanate and reacting and foaming to form polyurethane electromagnetic shielding material is S3. The polyurethane electromagnetic shielding material obtained by the invention can simultaneously realize light weight and high shielding efficiency of the material, and meanwhile, the material has good mechanical properties.

Owner:HEFEI UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com