Functional type powdery paint and preparation method thereof

A powder coating, functional technology, applied in the field of coatings, to achieve low cost, overcome the problem of agglomeration, and achieve the effect of large-scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

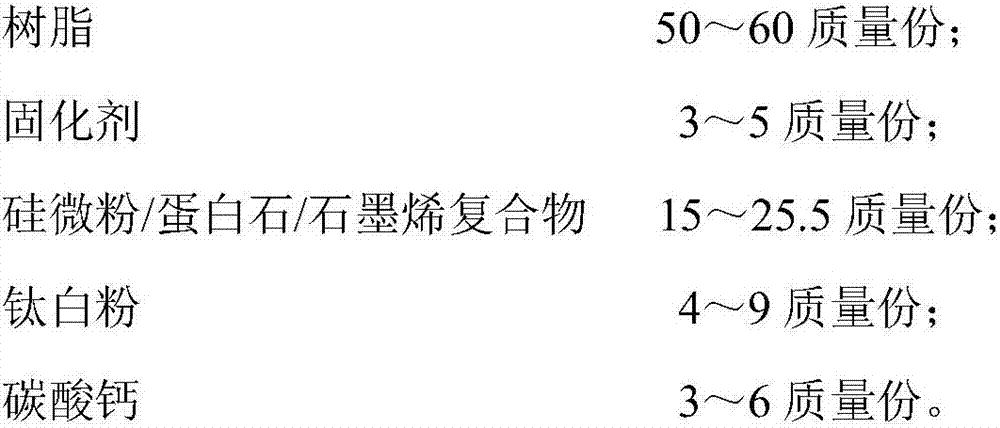

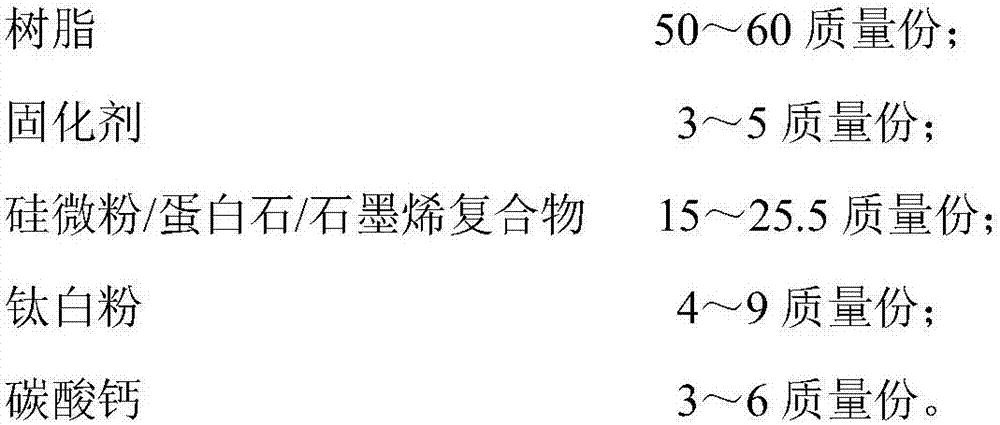

Method used

Image

Examples

Embodiment 1

[0048] 1. Preparation of microsilica powder / opal / graphene composite:

[0049] 1) Mix 3.0 g of KH560 coupling agent, 64.5 g of deionized water, and 34.5 g of ethanol evenly, adjust the pH to 4.0, stir at room temperature for 40 minutes to fully hydrolyze the coupling agent, and obtain a coupling agent hydrolyzate;

[0050] 2) Disperse 0.1g sulfonated graphene aqueous solution, 0.1g wetting agent (Triton CF-10), 0.2g dispersant (P-19), 1.3g p-toluenesulfonic acid in 50.0g deionized water, and heat to reflux , to obtain a graphene mixed solution;

[0051] 3) Add 1.0 g coupling agent hydrolyzate to the graphene mixed solution, and reflux reaction for 2 hours to obtain a coupling-modified graphene solution;

[0052] 4) 65g particle diameter is 50nm silicon micropowder and 65g coupling agent hydrolyzate are added in step 3) in the coupling modified graphene solution, insulation reaction 3.5 hours, obtain the coupling modified graphene / silicon micropowder solution;

[0053] 5) Add...

Embodiment 2

[0060] 1. Preparation of microsilica powder / opal / graphene composite:

[0061] 1) Mix 1.4g of KH792 coupling agent, 64.5g of deionized water, and 34.5g of ethanol evenly, adjust the pH to 4.0, stir at room temperature for 20 minutes to fully hydrolyze the coupling agent, and obtain a coupling agent hydrolyzate;

[0062] 2) Disperse 0.1g sulfonated graphene aqueous solution, 0.1g wetting agent (Triton CF-10), 0.2g dispersant (P-19), 1.3g p-toluenesulfonic acid in 50.0g deionized water, and heat to reflux , to obtain a graphene mixed solution;

[0063] 3) Add 1.0 g coupling agent hydrolyzate to the graphene mixed solution, and reflux reaction for 5 hours to obtain a coupling-modified graphene solution;

[0064] 4) 65g particle diameter is 50nm silicon micropowder and 65g coupling agent hydrolyzate are added in step 3) in the graphene solution of coupling modification, insulation reaction 2 hours, obtain the graphene / silicon micropowder of coupling modification solution;

[006...

Embodiment 3

[0072] 1. Preparation of microsilica powder / opal / graphene composite:

[0073] 1) Mix 2.0 g of KH550 coupling agent, 64.5 g of deionized water, and 34.5 g of ethanol evenly, adjust the pH to 4.0, stir at room temperature for 30 minutes to fully hydrolyze the coupling agent, and obtain a coupling agent hydrolyzate;

[0074] 2) Disperse 0.1g sulfonated graphene aqueous solution, 0.1g wetting agent (Triton CF-10), 0.2g dispersant (P-19), 1.3g p-toluenesulfonic acid in 50.0g deionized water, and heat to reflux , to obtain a graphene mixed solution;

[0075]3) Add 1.0 g coupling agent hydrolyzate to the graphene mixed solution, and reflux reaction for 4 hours to obtain a coupling-modified graphene solution;

[0076] 4) 65g particle diameter is 50nm silicon micropowder and 65g coupling agent hydrolyzate are added in the coupling modified graphene solution of step 3), insulation reaction 3 hours, obtain the coupling modified graphene / silicon micropowder solution;

[0077] 5) Add 34...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy value | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com