Composite separation membrane based on in situ growth organic framework structure of fluorine-containing copolymer and its preparation method and application

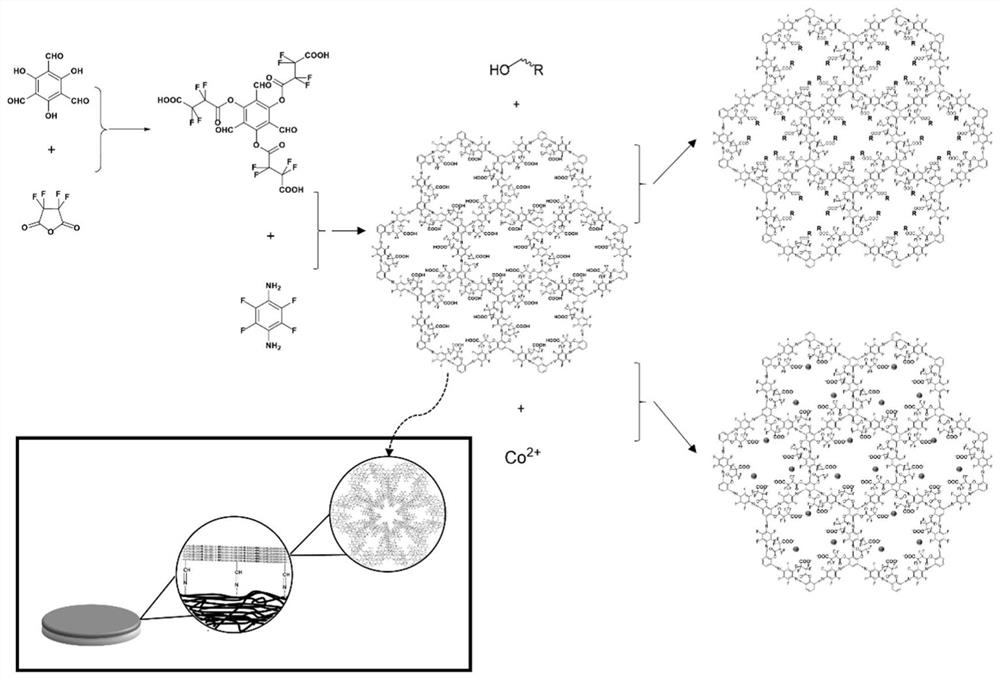

An organic framework and in-situ growth technology, applied in separation methods, semi-permeable membrane separation, dispersed particle separation, etc., can solve the problem of low selectivity of separation membrane materials, overcome the inability to prepare large areas, and achieve interface matching and The effect of close compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

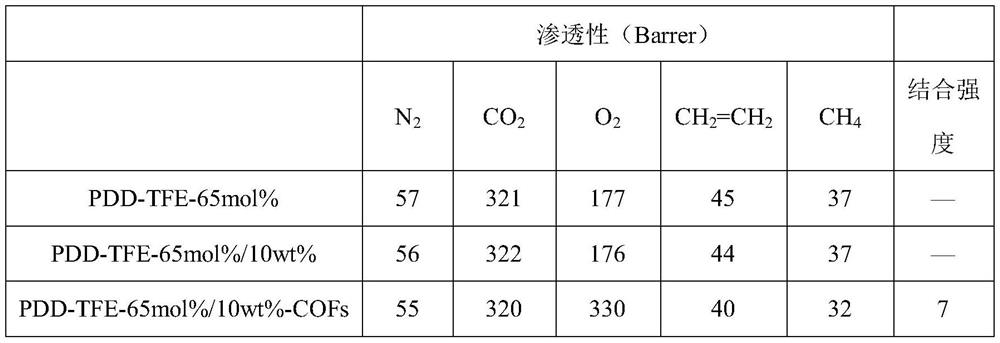

Embodiment 1

[0028] Add 140g of perfluoroheptane and 40g of perfluoroisopropanol into the autoclave, seal the nitrogen flow and exhaust oxygen until the oxygen concentration is less than 5ppm, and 0.084 moles (mol) of perfluoro-2,2-dimethyl -1,3-dioxole (PDD), 0.006mol of 4-penten-1-amine, and 0.038mol of tetrafluoroethylene were respectively added to the reaction kettle, and after stirring evenly, 0.53 Millimoles (mmol) of diisopropyl peroxydicarbonate (dissolved in 20g perfluoroheptane), stirred evenly and heated up to 50°C, polymerized for 6h, cooled to normal temperature, and unreacted tetrafluoroethylene monomer was removed, After the reaction, the solution was washed with tetrahydrofuran and methanol, and precipitated to obtain poly(perfluoro-2,2-dimethyl-1,3-dioxole-tetrafluoroethylene-4 -pentene-1-amine) random copolymer; after vacuum drying for 24h, take 0.2g of poly(perfluoro-2,2-dimethyl-1,3-dioxolane which can be further modified by reaction ene-tetrafluoroethylene-4-penten-1-...

Embodiment 2

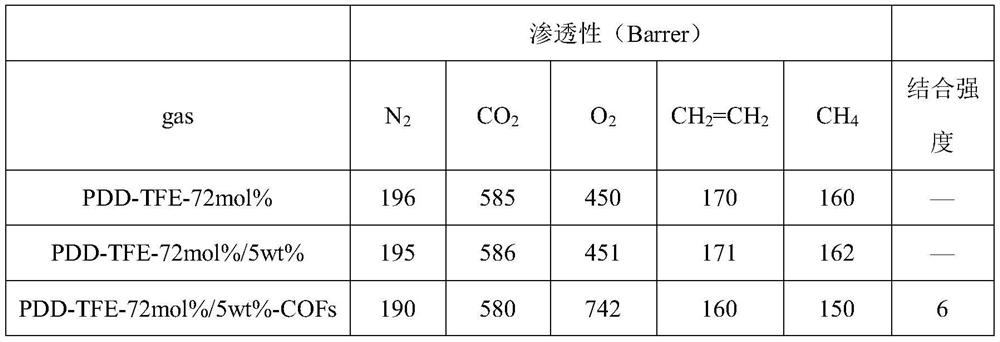

[0034] Add 130g of hexafluorobenzene and 50g of perfluoroisopropanol into the reactor, seal the nitrogen and discharge oxygen until the oxygen concentration is less than 5ppm, and add 0.082mol of perfluoro-2,2-dimethyl-1,3- Dioxole (PDD), 0.006mol of 5-hexen-1-amine, and 0.026mol of tetrafluoroethylene were added to the reaction kettle respectively, and after stirring evenly, 0.55 mmol of diperoxide was added by a booster pump. Diisopropyl carbonate (dissolved in 20g hexafluorobenzene), stir well and heat up to 45°C, polymerize for 8 hours, cool to room temperature, remove unreacted tetrafluoroethylene monomer, wash the reacted solution with tetrahydrofuran and methanol respectively , precipitation, to obtain a ternary random copolymer that can be further modified by reaction; after vacuum drying for 24 hours, take 0.1 g of a ternary random copolymer that can be further modified by reaction and 1.9 g of poly(perfluoro-2,2 -Dimethyl-1,3-dioxol-co-tetrafluoroethylene) copolymer ...

Embodiment 3

[0040]Add 130g of perfluoroheptane and 50g of perfluoroisopropanol into the reaction kettle, seal the nitrogen and discharge oxygen until the oxygen concentration is less than 5ppm, and add 0.102mol of perfluoro-2,2-dimethyl-1,3 - Dioxole (PDD), 0.014mol of 4-penten-1-amine, and 0.025mol of tetrafluoroethylene were added to the reaction kettle, and after stirring evenly, 0.68mmol of peroxide was added by a booster pump. Diisopropyl dicarbonate (dissolved in 20g perfluoroheptane), stirred evenly and heated to 45°C, polymerized for 8 hours, cooled to normal temperature, excluded unreacted tetrafluoroethylene monomer, and passed the reaction solution through tetrahydrofuran, Methanol washing and precipitation, to obtain a ternary random copolymer that can be further modified by reaction; after vacuum drying for 24 hours, take 0.1 g of a ternary random copolymer that can be further modified by reaction and 1.9 g of poly(perfluoro-2 , 2-Dimethyl-1,3-dioxole-co-tetrafluoroethylene) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com