Montmorillonite-modified silicon rubber nanocomposite and preparation method thereof

A silicone rubber nano-composite material technology, applied in the field of modified silicone rubber nano-composite materials and its preparation, can solve the limited increase in montmorillonite layer spacing and thermal stability, and improve the mechanical and thermal stability of polymers Insignificant and other problems, to achieve excellent mechanical and heat resistance, excellent processing performance, the effect of heat resistance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

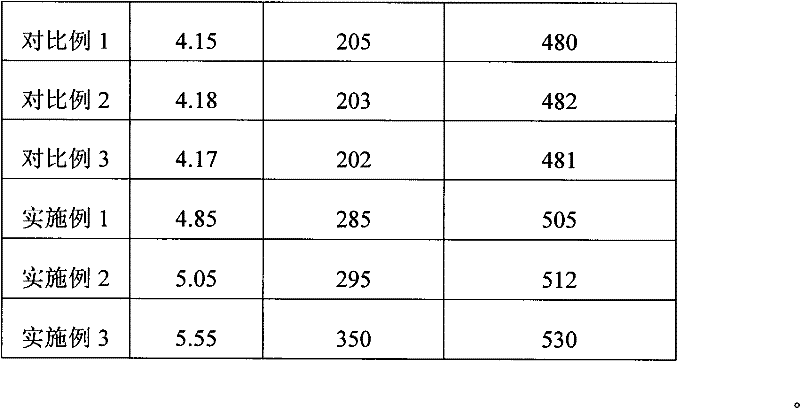

Embodiment 1

[0038] Weigh 92 grams of component A into a plastic beaker, add 1 gram of organic montmorillonite, and stir vigorously for 10 minutes to mix and disperse the montmorillonite and silicone rubber component A; then add 8 grams of component B And 0.1 g of chloroplatinic acid, stir vigorously to fully mix it with component A; put the plastic beaker into a vacuum oven with a vacuum of 80pa and vacuum at room temperature to exhaust the bubbles; take out the beaker and mix the mixture Pour into the Teflon mold, put the mold in a vacuum oven, the vacuum degree is 110pa, vacuum at room temperature, and discharge the air bubbles; put the mold with the sample into the 80 ℃ oven, and the curing reaction 50 After taking it out within minutes, the silicone rubber / organic montmorillonite nano composite material of the present invention can be obtained.

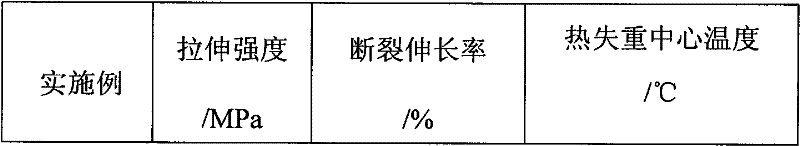

[0039] The tensile strength, elongation at break and center temperature of thermal weight loss of silicone rubber nanocomposites are shown in T...

Embodiment 2

[0041] Weigh 91 grams of component A in a plastic beaker, add 2 grams of organic montmorillonite, and stir vigorously for 20 minutes to make the montmorillonite and silicone rubber component A uniformly mixed and dispersed; then add 9 grams of component B And 0.2 g of chloroplatinic acid, stir vigorously to fully mix it with component A; put the plastic beaker into a vacuum oven with a vacuum of 90pa and vacuum at room temperature to exhaust the bubbles; take out the beaker and mix the mixture Pour into the Teflon mold, put the mold into a vacuum oven, the vacuum degree is 120pa, vacuum at room temperature, and discharge the bubbles; put the mold weighing the sample into the oven at 100℃, and the curing reaction 40 After taking it out within minutes, the silicone rubber / organic montmorillonite nano composite material of the present invention can be obtained.

[0042] The tensile strength, elongation at break and center temperature of thermal weight loss of silicone rubber nanocom...

Embodiment 3

[0044] Weigh 90 grams of component A in a plastic beaker, add 3 grams of organic montmorillonite, and stir vigorously for 30 minutes to make the montmorillonite and silicone rubber component A uniformly mixed and dispersed; then add 10 grams of component B And 0.3 g of chloroplatinic acid, stir vigorously to fully mix it with component A; put the plastic beaker into a vacuum oven with a vacuum of 100pa and vacuum at room temperature to exhaust the bubbles; take out the beaker and mix the mixture Pour into the Teflon mold, put the mold into a vacuum oven, the vacuum degree is 130pa, vacuum at room temperature, and discharge the bubbles; put the mold weighing the sample into the oven at 120℃, and the curing reaction is 30 After taking it out within minutes, the silicone rubber / organic montmorillonite nano composite material of the present invention can be obtained.

[0045] The tensile strength, elongation at break and center temperature of thermal weight loss of silicone rubber na...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com