A kind of supramolecular flame-retardant silicone rubber and preparation method thereof

A supramolecular and silicone rubber technology, applied in the field of silicone rubber and its preparation, supramolecular flame retardant silicone rubber and its preparation, can solve the problems of general flame retardant effect of glass fiber, achieve strong practical value, and have flame retardancy , high flame retardancy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

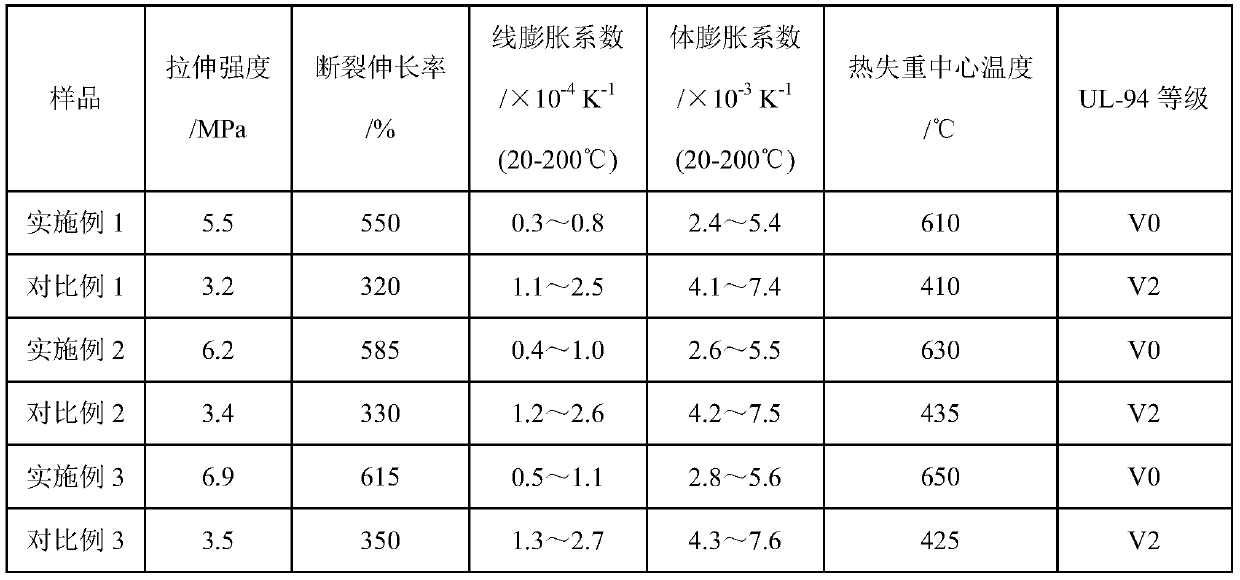

Examples

Embodiment 1

[0033] 1. Preparation of supramolecular glass fiber:

[0034] A) Put 10g of glass fibers into 100mL of toluene, stir and mix evenly at room temperature under nitrogen protection;

[0035] B) Add 40g of ammonium bisphosphate, react at 100°C for 6 hours, then vacuumize to remove toluene;

[0036] C) cooling to 70° C., adding 20 g of ferrous chloride, stirring and reacting for 3 hours, followed by rinsing and drying;

[0037] D) repeating the above steps A) to C) several times to make the thickness of the film reach 15 nanometers, that is, to obtain the supramolecular glass fiber.

[0038] Table 1 shows the characteristic wavenumbers of the infrared spectrum of the glass fiber and the obtained supramolecular glass fiber.

[0039] 2. Preparation of supramolecular flame retardant silicone rubber:

[0040] a) Add 10 grams of supramolecular glass fibers to 90 grams of polysiloxane containing vinyl end groups, and stir evenly at room temperature to obtain a mixture;

[0041] b) Ad...

Embodiment 2

[0047] 1. Preparation of supramolecular glass fiber:

[0048] A) Put 15g of glass fiber into 100mL of toluene, stir and mix evenly at room temperature under nitrogen protection;

[0049] B) Add 60g of ammonium bisphosphate, react at 110°C for 4 hours, then vacuumize to remove toluene;

[0050] C) cooling to 80° C., adding 25 g of ferrous chloride, stirring and reacting for 2 hours, rinsing and drying;

[0051] D) repeating the above steps A) to C) several times to make the thickness of the film reach 20 nanometers, that is, to obtain the supramolecular glass fiber.

[0052] Table 1 shows the characteristic wavenumbers of the infrared spectrum of the glass fiber and the obtained supramolecular glass fiber.

[0053] 2. Preparation of supramolecular flame retardant silicone rubber:

[0054] a) Add 15 grams of supramolecular glass fibers to 93 grams of polysiloxane containing vinyl end groups, and stir evenly at room temperature to obtain a mixture;

[0055] b) Add 8 grams of ...

Embodiment 3

[0061] 1. Preparation of supramolecular glass fiber:

[0062] A) Put 20g of glass fiber into 100mL of toluene, stir and mix evenly at room temperature under nitrogen protection;

[0063] B) Add 80g of ammonium bisphosphate, react at 120°C for 1 hour, then vacuumize to remove toluene;

[0064] C) cooling to 90° C., adding 30 g of ferrous chloride, stirring and reacting for 1 hour, rinsing and drying;

[0065] D) repeating the above steps A) to C) several times to make the thickness of the film reach 25 nanometers, that is, to obtain the supramolecular glass fiber.

[0066] The characteristic wavenumbers of infrared spectra of glass fibers and supramolecular glass fibers are shown in Table 1.

[0067] 2. Preparation of supramolecular flame retardant silicone rubber:

[0068] a) Add 20 grams of supramolecular glass fibers to 95 grams of polysiloxane containing vinyl end groups, and stir evenly at room temperature to obtain a mixture;

[0069] b) Add 10 grams of hydrogen-conta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com