Intumescent flame retardant as well as preparation method and application thereof

A technology of intumescent flame retardant and expanded vermiculite, which is applied in coatings, fireproof coatings, etc., can solve the problems of mechanical properties, physical and chemical properties of paint films, poor compatibility between flame retardants and resins, and decreased water resistance of coatings. , to achieve stable storage, good corrosion resistance, and improved airtightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

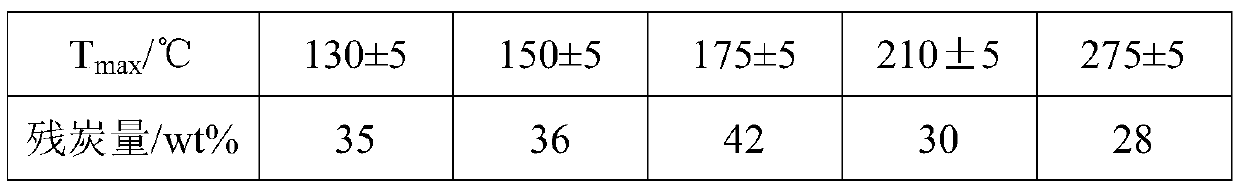

Embodiment 1

[0050] One, the preparation of diethyl hypophosphite:

[0051] Sodium diethyl hypophosphite was dissolved in deionized water to form an aqueous solution of sodium diethyl hypophosphite with a concentration of 4 wt%, and 10 wt% dilute sulfuric acid was added to adjust the pH of the solution to 3 to obtain a mixed solution;

[0052] Heat the mixed solution to 75°C, slowly drop in equivalent aluminum sulfate aqueous solution under stirring, after the dropwise addition is complete, keep the reaction for 30 minutes, finish the reaction, filter, wash the filter cake with deionized water, and then vacuum dry at 130°C. A white powder is obtained, which is aluminum diethyl hypophosphite.

[0053] 2. Preparation of composite flame retardants:

[0054] The char-forming catalyst, foaming agent, char-forming agent, and diethyl hypophosphite are compounded and mixed according to the mass ratio of 8:6:5:3 to obtain a composite flame retardant, which is set aside.

[0055] 3. Preparation of...

Embodiment 2

[0068] One, the preparation of diethyl hypophosphite:

[0069] Sodium diethyl hypophosphite was dissolved in deionized water to form an aqueous solution of sodium diethyl hypophosphite with a concentration of 4 wt%, and 10 wt% dilute sulfuric acid was added to adjust the pH of the solution to 3 to obtain a mixed solution;

[0070] Heat the mixed solution to 75°C, slowly drop in an equivalent amount of magnesium sulfate aqueous solution under stirring, after the dropwise addition is complete, keep the reaction for 30 minutes, finish the reaction, filter, wash the filter cake with deionized water, and then vacuum-dry it at 130°C. A white powder is obtained, which is magnesium diethyl hypophosphite.

[0071] 2. Preparation of composite flame retardants:

[0072] The char-forming catalyst, foaming agent, char-forming agent, and diethyl hypophosphite are compounded and mixed according to the mass ratio of 10:7:6:4 to obtain a composite flame retardant, which is set aside.

[0073...

Embodiment 3

[0086] One, the preparation of diethyl hypophosphite:

[0087] Sodium diethyl hypophosphite was dissolved in deionized water to form an aqueous solution of sodium diethyl hypophosphite with a concentration of 4 wt%, and 10 wt% dilute sulfuric acid was added to adjust the pH of the solution to 3 to obtain a mixed solution;

[0088] Heat the mixed solution to 80°C, slowly drop into an equivalent zinc sulfate aqueous solution under stirring, after the dropwise addition is complete, keep the reaction for 40 minutes, finish the reaction, filter, and vacuum dry the filter cake at 130°C after being washed with deionized water. A white powder is obtained, which is zinc diethyl hypophosphite.

[0089] 2. Preparation of composite flame retardants:

[0090] The char-forming catalyst, foaming agent, char-forming agent, and diethyl hypophosphite are compounded and mixed according to the mass ratio of 12:8:7:5 to obtain a composite flame retardant, which is set aside.

[0091] 3. Preparat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com