Water-based coil steel repair paint and preparation method thereof

A technology for refinishing paint and steel coil, applied in the field of refinishing paint, can solve the problems of consuming manpower and financial resources, weak construction ability with rust, etc., and achieve the effect of strong construction ability with rust, no solvent pollution, and excellent alkali resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

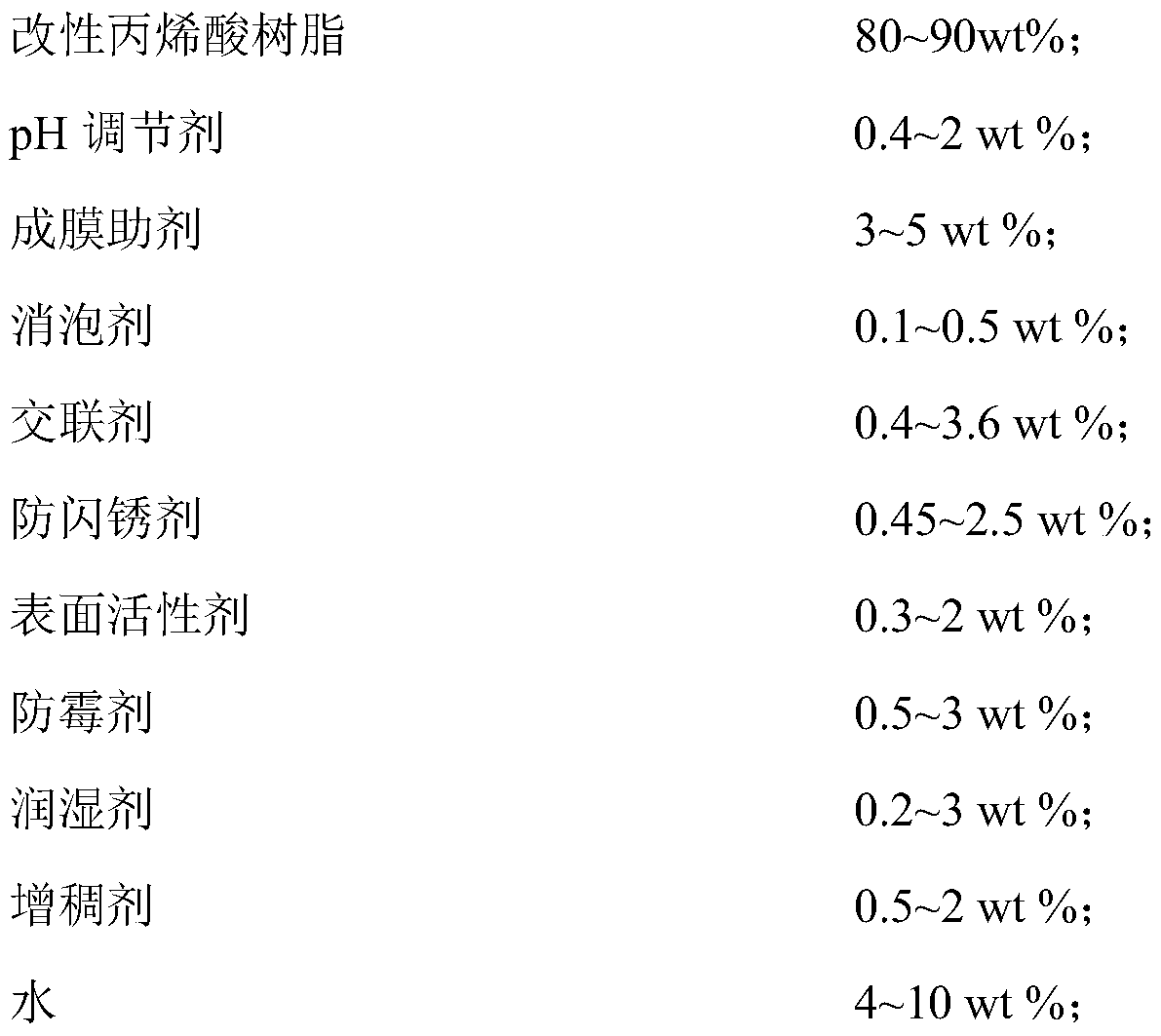

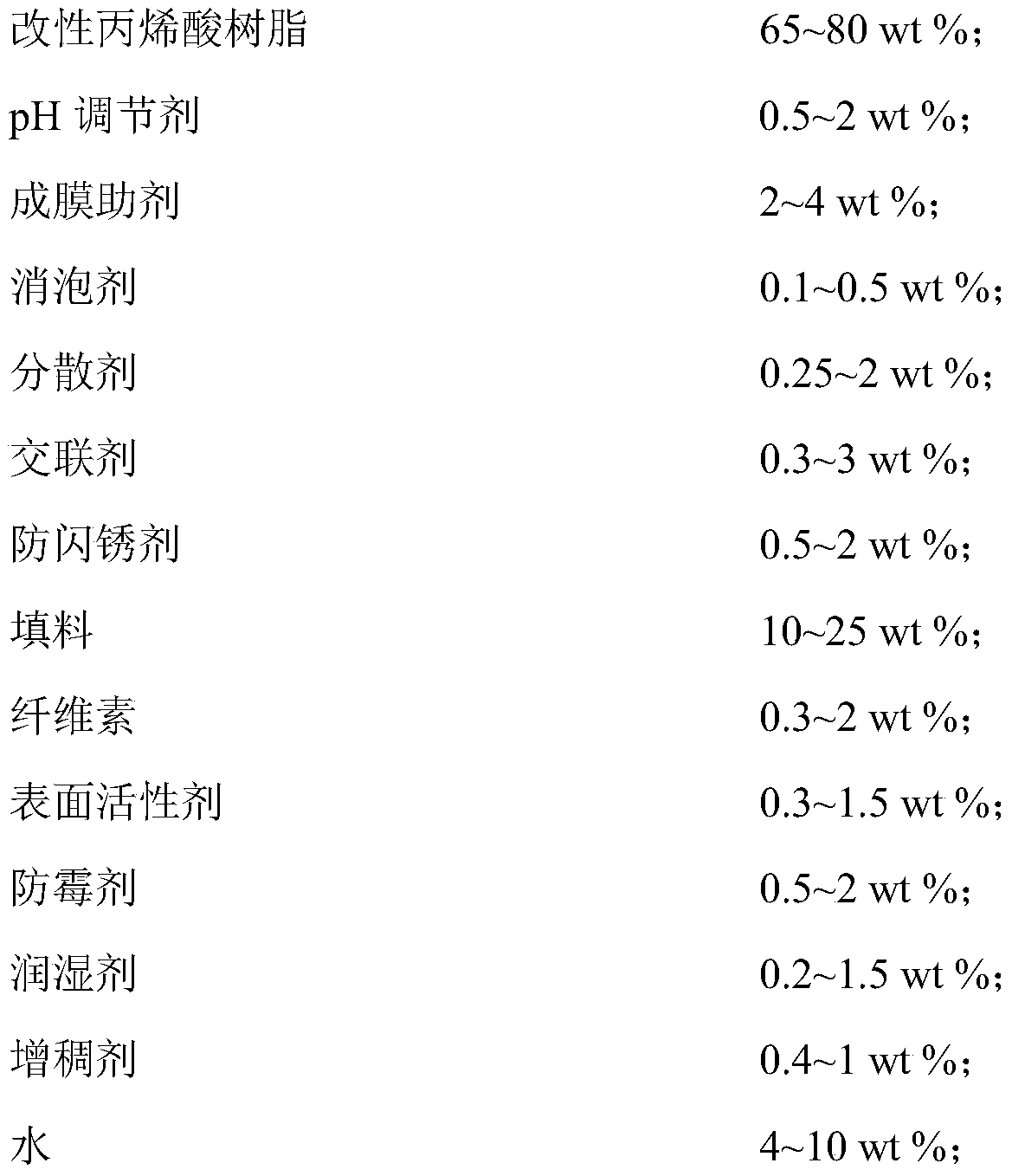

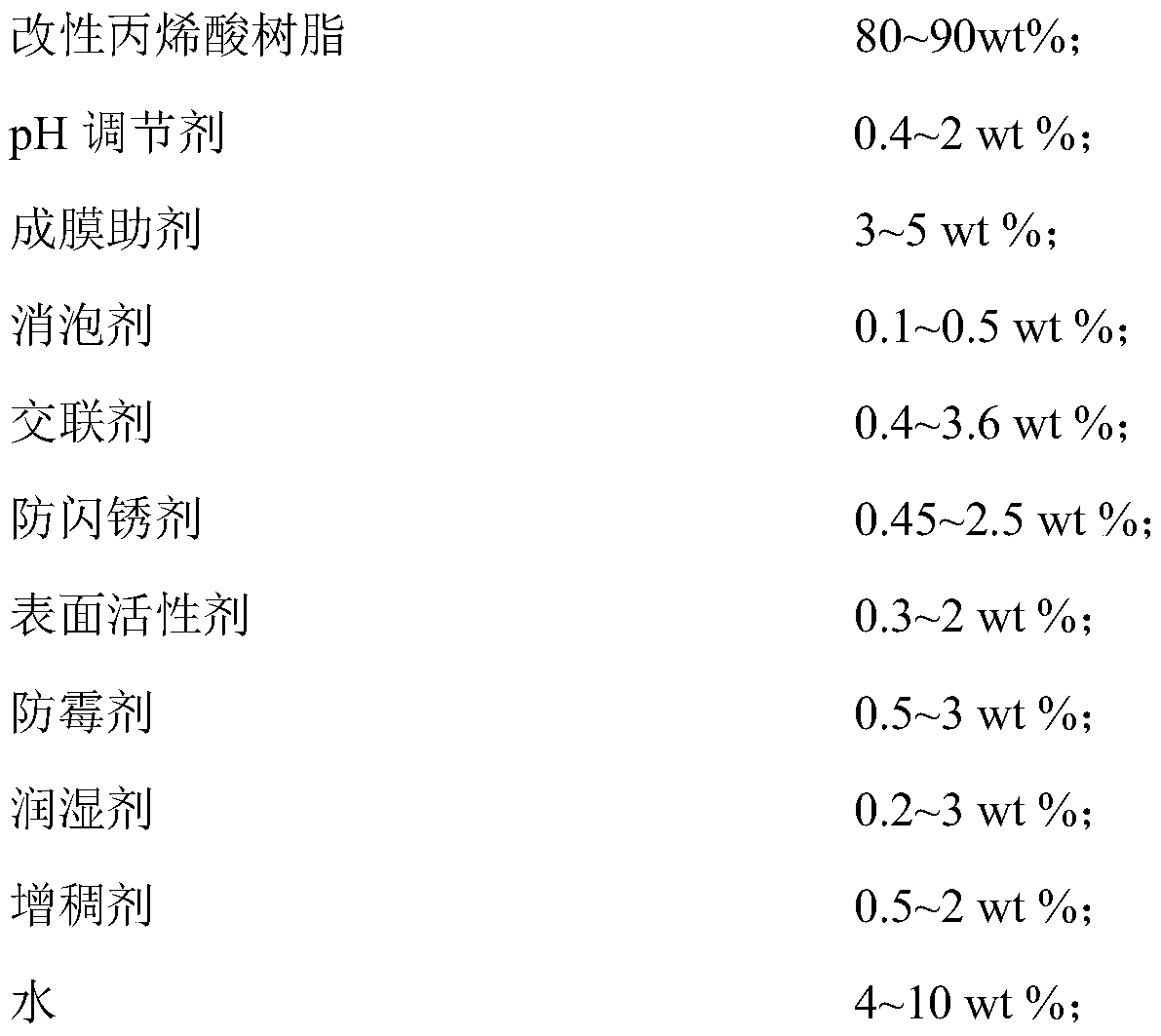

Method used

Image

Examples

Embodiment 1

[0052] One, the preparation of modified acrylic resin:

[0053] a) Mix n-butyl titanate: tetraethyl orthosilicate: γ-methacryloxypropyltrimethoxysilane at a mass ratio of 10:85:5 to obtain a titanium-silicon mixture for later use;

[0054] b) Mix water and ethanol according to a mass ratio of 1:5 to prepare an aqueous ethanol solution for later use; take 1 mass part of the titanium-silicon mixture, add 6 mass parts of an ethanol aqueous solution, and stir to disperse the titanium-silicon mixture in the ethanol aqueous solution, To obtain a titanium-silicon mixture, then add 5wt% glacial acetic acid to the titanium-silicon mixture to adjust the pH of the solution to 5.5, then stir and react at 30°C for 5 hours until n-butyl titanate, tetraethyl orthosilicate Hydrolyze it into titanium dioxide and silicon dioxide respectively to obtain a mixed solution of titanium-silicon nanoparticles;

[0055] c) Add 2 parts by mass of 10 wt% ammonium persulfate aqueous solution to the mixed ...

Embodiment 2

[0070] One, the preparation of modified acrylic resin:

[0071] a) Mix n-butyl titanate: tetraethyl orthosilicate: γ-methacryloxypropyltrimethoxysilane at a mass ratio of 15:75:10 to obtain a titanium-silicon mixture for later use;

[0072] b) Mix water and ethanol according to the mass ratio of 1:4 to prepare an aqueous ethanol solution for later use; take 1 mass part of the titanium-silicon mixture, add 5 mass parts of an ethanol aqueous solution, stir, and disperse the titanium-silicon mixture in the ethanol aqueous solution, To obtain a titanium-silicon mixture, then add 8wt% glacial acetic acid to the titanium-silicon mixture to adjust the pH of the solution to 4.5, then stir and react at 40°C for 3 hours until n-butyl titanate, tetraethyl orthosilicate Hydrolyze it into titanium dioxide and silicon dioxide respectively to obtain a mixed solution of titanium-silicon nanoparticles;

[0073] c) Add 3.5 parts by mass of 10 wt% ammonium persulfate aqueous solution to the mix...

Embodiment 3

[0088] One, the preparation of modified acrylic resin:

[0089] a) Mix n-butyl titanate: tetraethyl orthosilicate: γ-methacryloxypropyltrimethoxysilane at a mass ratio of 20:70:10 to obtain a titanium-silicon mixture for later use;

[0090] b) Mix water and ethanol according to a mass ratio of 1:3 to prepare an aqueous ethanol solution for later use; take 1 mass part of the titanium-silicon mixture, add 4 mass parts of an ethanol aqueous solution, and stir to disperse the titanium-silicon mixture in the ethanol aqueous solution, To obtain a titanium-silicon mixture, then add 10 wt% glacial acetic acid to the titanium-silicon mixture to adjust the pH of the solution to 3.5, then stir and react at 50°C for 2 hours until n-butyl titanate, tetraethyl orthosilicate Hydrolyze it into titanium dioxide and silicon dioxide respectively to obtain a mixed solution of titanium-silicon nanoparticles;

[0091] c) Add 5 parts by mass of 10 wt% ammonium persulfate aqueous solution to the mix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com