A kind of water-based quick-drying coil coating based on monodisperse polyacrylic acid resin and preparation method thereof

A polyacrylic resin, acrylic resin technology, applied in anti-corrosion coatings, coatings, etc., to achieve excellent quick-drying performance, good dispersibility, and broad application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

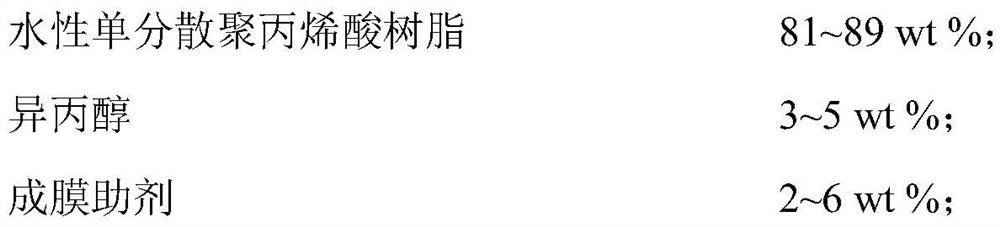

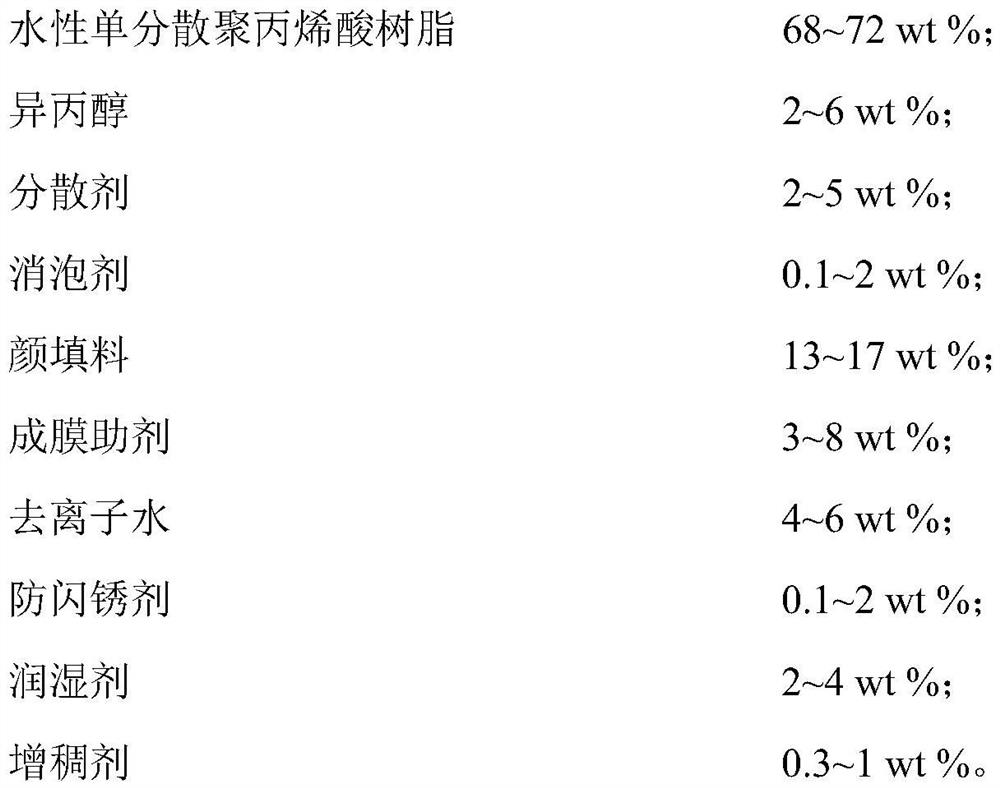

Image

Examples

Embodiment 1

[0051] 1. Preparation of water-based monodisperse acrylic resin:

[0052] a) Methyl methacrylate monomer, butyl acrylate monomer, and N-methylol acrylamide monomer are mixed to obtain a mixed monomer, which is set aside; acrylic acid monomer is taken, set aside; one-third of the mixed monomer body and one-third of the acrylic monomer, wherein the mass ratio of acrylic monomer: methyl methacrylate monomer: butyl acrylate monomer: N-methylol acrylamide monomer is 15:28:15 : 30, to obtain an acrylic monomer; mix OP-10 and sodium dodecylbenzenesulfonate according to a mass ratio of 5:1 to obtain an emulsifier, which is selected according to a mass ratio of emulsifier to acrylic monomer of 9:100 An appropriate amount of emulsifier is used for later use; according to the mass ratio of the initiator to the total monomer (that is, the total amount of mixed monomer + acrylic acid monomer) is 0.5:100, an appropriate amount of ammonium persulfate (initiator) is taken for later use; The ...

Embodiment 2

[0064] 1. Preparation of water-based monodisperse acrylic resin:

[0065] a) Methyl methacrylate monomer, butyl acrylate monomer, and N-methylol acrylamide monomer are mixed to obtain a mixed monomer, which is set aside; acrylic acid monomer is taken, set aside; one-third of the mixed monomer Body and one-third of the acrylic monomer, wherein the mass ratio of acrylic monomer: methyl methacrylate monomer: butyl acrylate monomer: N-methylol acrylamide monomer is 18:26:17 : 29, to obtain an acrylic monomer; mix OP-10 and sodium dodecylbenzenesulfonate according to a mass ratio of 5:1 to obtain an emulsifier, which is selected according to a mass ratio of emulsifier to acrylic monomer of 8.6:100 An appropriate amount of emulsifier is used for subsequent use; according to the mass ratio of the initiator to the total monomer (that is, the total amount of mixed monomer + acrylic acid monomer) is 0.45:100, an appropriate amount of ammonium persulfate (initiator) is taken for subseque...

Embodiment 3

[0077] 1. Preparation of water-based monodisperse acrylic resin:

[0078] a) Methyl methacrylate monomer, butyl acrylate monomer, and N-methylol acrylamide monomer are mixed to obtain a mixed monomer, which is set aside; acrylic acid monomer is taken, set aside; one-third of the mixed monomer Body and one-third of the acrylic monomer, wherein the mass ratio of acrylic monomer: methyl methacrylate monomer: butyl acrylate monomer: N-methylol acrylamide monomer is 18:27:15 : 31, to obtain an acrylic monomer; mix OP-10 and sodium dodecylbenzenesulfonate according to a mass ratio of 5:1 to obtain an emulsifier, which is selected according to a mass ratio of emulsifier to acrylic monomer of 8.5:100 An appropriate amount of emulsifier is used for subsequent use; according to the mass ratio of the initiator to the total monomer (that is, the total amount of mixed monomer + acrylic acid monomer) is 0.48:100, an appropriate amount of ammonium persulfate (initiator) is taken for subseque...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com