A kind of light-weight high-strength high electromagnetic shielding efficiency material and preparation method thereof

An electromagnetic shielding material and electromagnetic shielding technology, applied in the fields of magnetic field/electric field shielding, electrical components, etc., can solve the problems of light weight and low shielding efficiency, and achieve lightweight electromagnetic shielding efficiency, excellent mechanical properties, economical and practical preparation process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

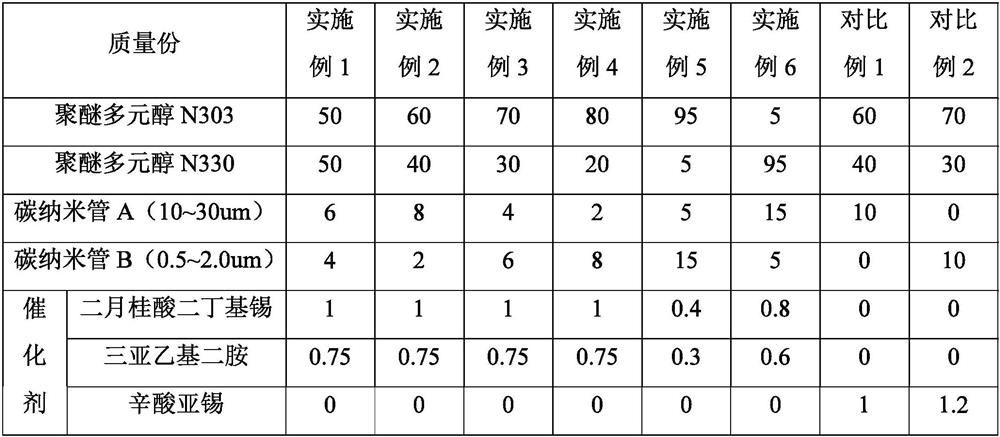

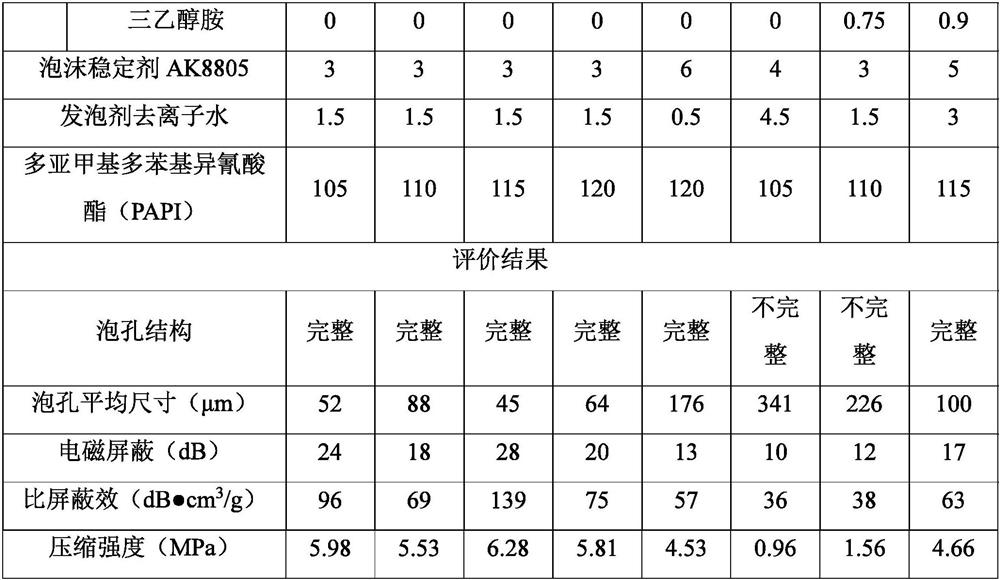

[0027] The invention discloses a light-weight, high-strength, high-electromagnetic shielding performance material and a preparation method thereof. The raw materials include the following components in parts by mass: 100 parts of mixed polyether polyol, 0.7-2.1 parts of catalyst, and 3-3 parts of foam stabilizer 6 parts, 0.5-4.5 parts of water, 2-20 parts of composite carbon nanotubes, 105-120 parts of polyisocyanate.

[0028] Mixed polyether polyols are composed of one or more polyether polyols mixed in a certain proportion, and the total mass fraction is 100 parts; the functionality of polyether polyols is 2-4, the number-average molecular weight is 300-2000, and the viscosity is 300~1000mPa·s.

[0029] The composite carbon nanotubes are composed of carbon nanotubes A and carbon nanotubes B mixed in a certain proportion, the sum of the parts by mass is 2 to 20 parts, and the length of the carbon nanotubes A is at least 10 to 20 parts of the length of the carbon nanotubes B. ...

Embodiment 1

[0038] The preparation method step of polyurethane electromagnetic shielding material is as follows:

[0039] S1. Weigh 50 parts of polyether polyol N330 and 50 parts of polyether polyol N303 into a three-necked flask and mix them mechanically for 10 minutes to obtain a uniform mixed polyether polyol. Dehydration for 2 hours;

[0040]S2, add 6 parts of carbon nanotubes A and 4 parts of carbon nanotubes B, 1.75 parts of composite catalysts (1 part of dibutyltin dilaurate and 0.75 parts of triethylenediamine), 3 parts of carbon nanotubes B, 3 parts of mixed polyether polyols after dehydration successively 1 part of AK8805 and 1.5 parts of deionized water, stirred for 10 minutes, so that the slurry was fully stirred, mixed and dispersed, and a polyether polyol slurry with uniform dispersion of each component was obtained;

[0041] S3. Take 105 parts of polymethylene polyphenyl isocyanate (PAPI) and add it to the polyether polyol slurry, and stir it rapidly for 30 seconds, pour t...

Embodiment 2

[0043] The preparation method step of polyurethane electromagnetic shielding material is as follows:

[0044] S1. Weigh 60 parts of polyether polyol N330 and 40 parts of polyether polyol N303 into a three-necked flask and mix them mechanically for 10 minutes to obtain a uniform mixed polyether polyol. Dehydration for 2 hours;

[0045] S2, add 8 parts of carbon nanotubes A and 2 parts of carbon nanotubes B, 1.75 parts of composite catalysts (1 part of dibutyltin dilaurate and 0.75 parts of triethylenediamine), 3 parts of carbon nanotubes B, 3 parts of mixed polyether polyols after dehydration successively 1 part of AK8805 and 1.5 parts of deionized water, stirred for 10 minutes, so that the slurry was fully stirred, mixed and dispersed, and a polyether polyol slurry with uniform dispersion of each component was obtained;

[0046] S3. Take 110 parts of polymethylene polyphenyl isocyanate (PAPI) and add it to the polyether polyol slurry, and stir it fully for 30 seconds quickly,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com