Hot vulcanization type flame-retardant silicon rubber composite material and preparation method of hot vulcanization type flame-retardant silicon rubber composite material

A composite material, thermal vulcanization technology, applied in chemical instruments and methods, boron compounds, inorganic chemistry, etc., to achieve the effects of easy large-scale production, strong controllability, and improved flame retardant and smoke suppression properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

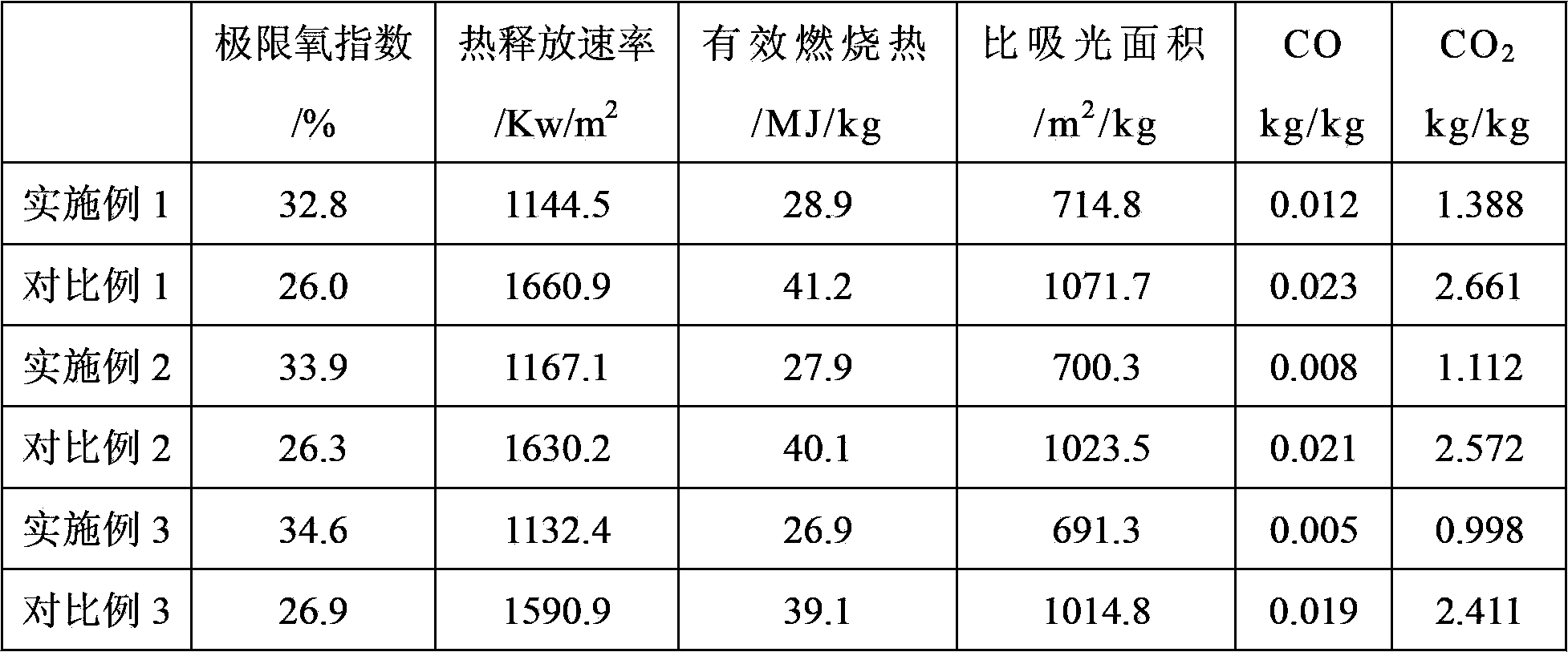

Embodiment 1

[0028] 4 moles of Zn(NO 3 ) 2 ·6H 2 O and 1 mole of Fe(NO 3 ) 3 9H 2 O was dissolved in 1 liter of water to prepare a mixed brine solution; 2 moles of NaOH and 1 mole of Na 2 B 4 o 7 10H 2 O was dissolved in 1 liter of water to prepare a mixed alkaline aqueous solution; at a temperature of 40°C and a stirring speed of 2000 rpm, the above-mentioned mixed alkaline aqueous solution was dropped dropwise into the above-mentioned mixed salt solution until the mixed solution system formed The pH value is 9; the obtained product is aged at 60°C for 24 hours, then washed with acetone, and then dried at 80°C for 24 hours to obtain a hydrotalcite-like substance containing zinc, boron and iron.

[0029] Weigh 85 grams of methyl vinyl silicone rubber raw rubber and 15 grams of hydrotalcites containing zinc, boron and iron, and mix them evenly on an open mill; then add 0.2 grams of vulcanizing agent 2,5-dimethyl-2 , 5-bis-(tert-butylperoxy)hexane, after mixing evenly, the film is r...

Embodiment 2

[0035] 4.5 moles of Zn(NO 3 ) 2 ·6H 2 O and 1 mole of Fe(NO 3 ) 3 9H 2 O was dissolved in 2 liters of water to prepare a mixed brine solution; 2.5 moles of NaOH and 1 mole of Na 2 B 4 o 7 10H 2 O was dissolved in 2 liters of water to prepare a mixed alkali aqueous solution; at a temperature of 50°C and a stirring speed of 1750 rpm, the above-mentioned mixed alkali aqueous solution was dropped dropwise into the above-mentioned mixed salt solution until the mixed solution system formed The pH value is 9.5; the obtained product is aged at 65°C for 21 hours, washed with acetone, and dried at 85°C for 18 hours to obtain a hydrotalcite-like substance containing zinc, boron and iron.

[0036]Weigh 90 grams of methyl vinyl silicone rubber raw rubber and 10 grams of hydrotalcites containing zinc, boron and iron, and mix them evenly on an open mill; then add 0.4 grams of vulcanizing agent 2,5-dimethyl-2 , 5-bis-(tert-butylperoxy)hexane, after mixing evenly, the film is released...

Embodiment 3

[0042] 5 moles of Zn(NO 3 ) 2 ·6H 2 O and 1 mole of Fe(NO 3 ) 3 9H 2 O was dissolved in 3 liters of water to prepare a mixed salt solution; 3 moles of NaOH and 1 mole of Na 2 B 4 o 7 10H 2 O was dissolved in 3 liters of water to prepare a mixed alkali aqueous solution; at a temperature of 60°C and a stirring speed of 1500 rpm, the above-mentioned mixed alkali aqueous solution was dropped dropwise into the above-mentioned mixed salt solution until the mixed solution system formed The pH value is 10; the obtained product is aged at 70°C for 18 hours, washed with acetone, and dried at 90°C for 12 hours to obtain a hydrotalcite-like substance containing zinc, boron and iron.

[0043] Weigh 95 grams of methyl vinyl silicone rubber raw rubber and 5 grams of hydrotalcites containing zinc, boron and iron, and mix evenly on an open mill; then add 0.6 grams of vulcanizing agent 2,5-dimethyl-2 , 5-bis-(tert-butylperoxy)hexane, after mixing evenly, release the film; vulcanize the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com