High temperature resistant and thermal tear resistant fluororubber material and preparation technology thereof

A fluororubber, high temperature resistant technology, applied in the field of rubber materials, can solve the problems of decreased mechanical properties, easy to be damaged in use, easy to produce thermal tearing, etc., and achieve the effects of low cost, improved tear strength, and high resilience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

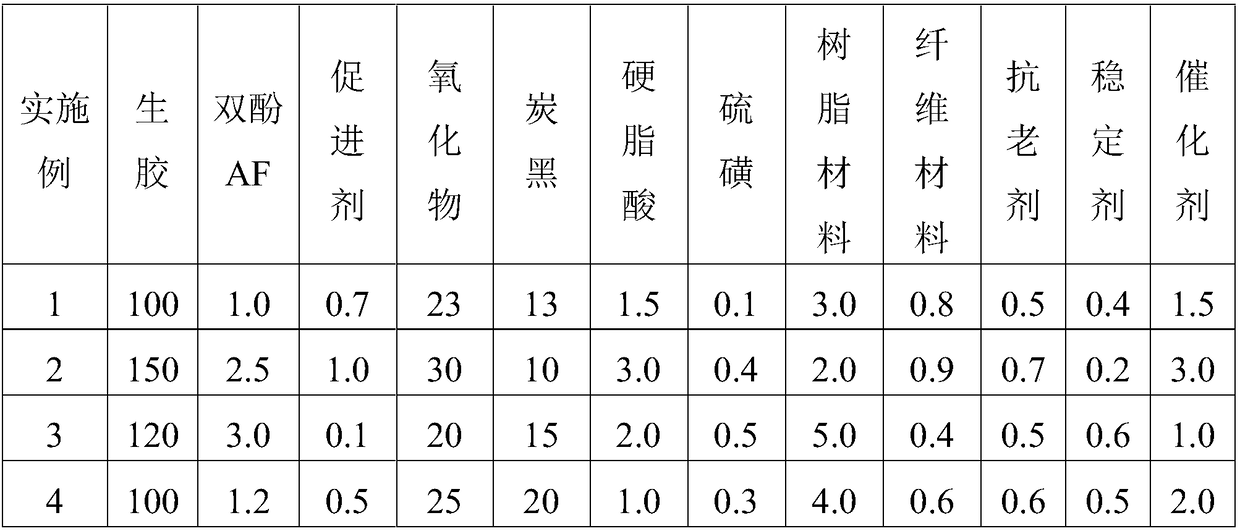

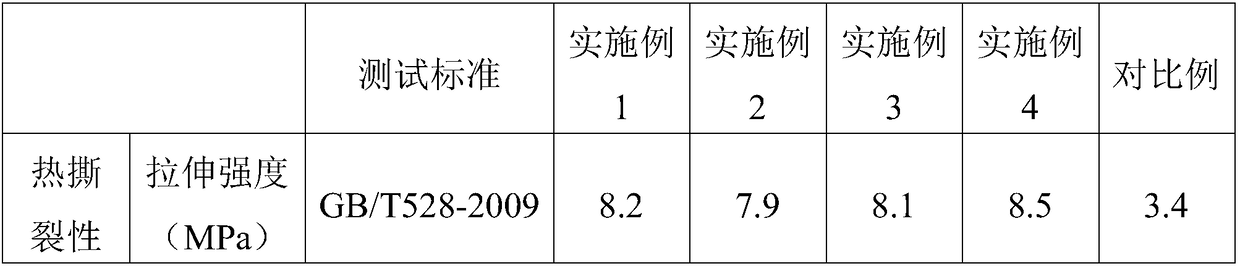

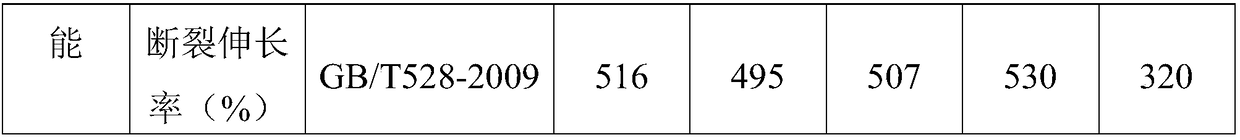

[0030] Embodiment: a kind of high-temperature-resistant, heat-tear-resistant fluororubber material, the components of the fluororubber material (by weight) include raw rubber 100-150 parts, bisphenol AF1-3 parts, accelerator 0.1- 1 part, 20-30 parts of oxide, 10-20 parts of carbon black, 1-3 parts of stearic acid, 0.1-0.5 parts of sulfur, 2-5 parts of resin material, 0.4-0.9 parts of fiber material, 0.5- 0.7 parts, 0.2-0.6 parts of stabilizer and 1-3 parts of catalyst;

[0031] The raw rubber includes vinylidene fluoride, tetrafluoroethylene, perfluoromethyl vinyl ether and hexafluoropropylene terpolymer, and the vinylidene fluoride, tetrafluoroethylene, perfluoromethyl vinyl ether and hexafluoropropylene The ratio of parts by weight of the four terpolymers is 1: (20-40): 1: (15-50); the raw rubber is made by the following steps: vinylidene fluoride, tetrafluoroethylene, perfluoromethane Vinyl ether and hexafluoropropylene terpolymer are sequentially added to the mixer accord...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com