In-situ preparation method for acidic aluminum chlorate ionic liquid loaded SBA-15 catalyst and application

An ionic liquid, in-situ preparation technology, applied in the field of mesoporous materials, can solve the problems of single way of immobilizing ionic liquid, high viscosity of ionic liquid, difficult post-processing process, etc., and achieve cost reduction, easy separation and reduction of ionic liquid loss. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

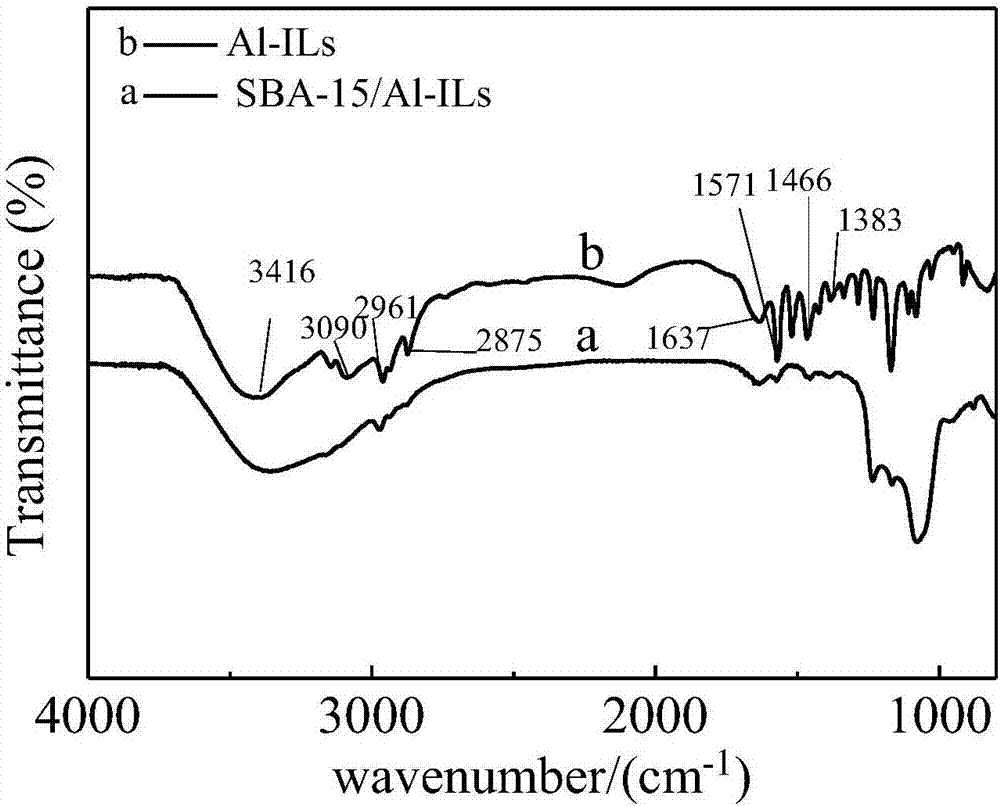

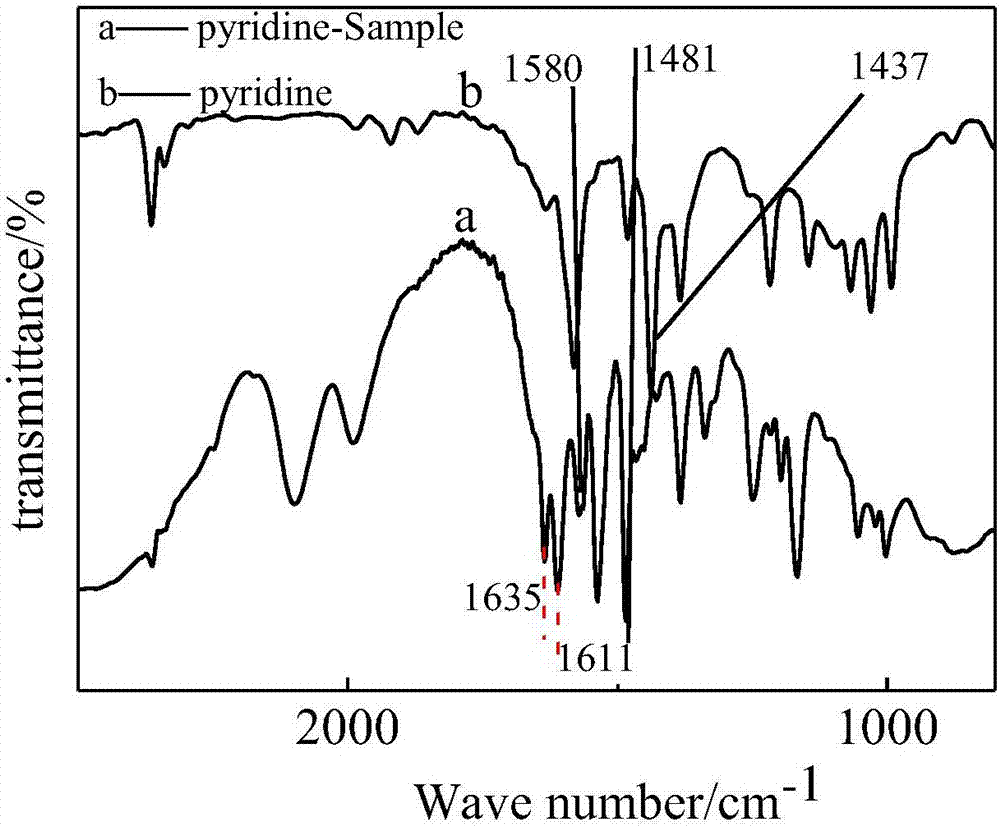

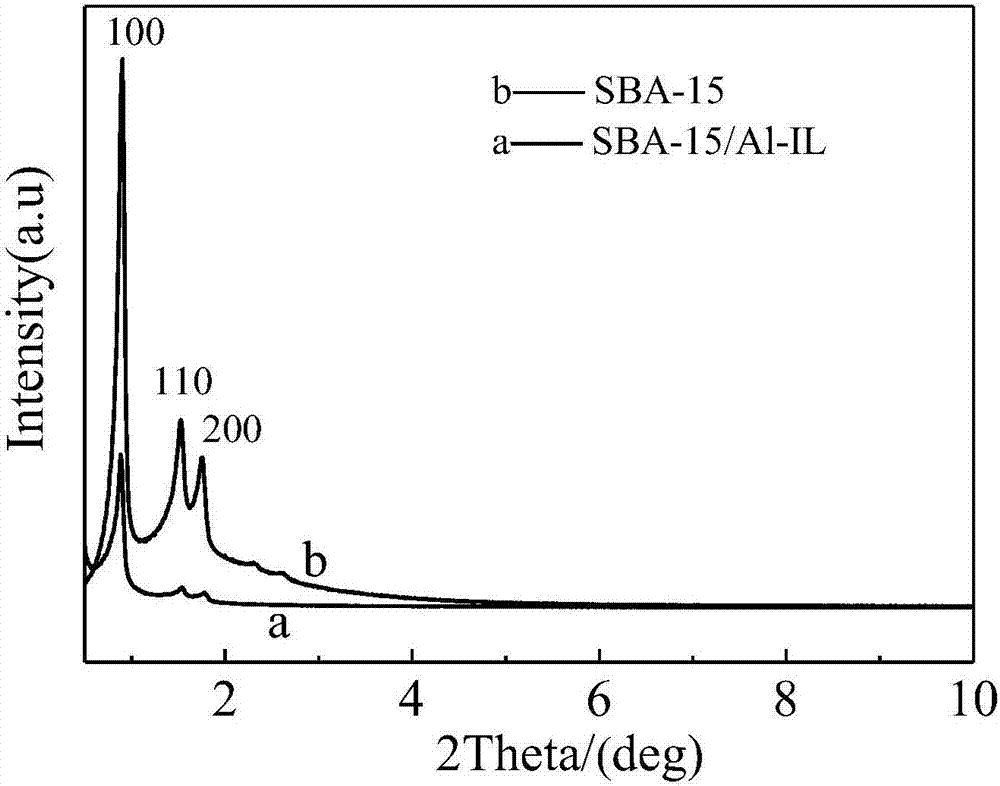

Embodiment 1

[0034] First prepare SBA-15, and then according to the way of in-situ loading, highly disperse the reaction raw materials of ionic liquid methylimidazole and n-chlorobutane on the inner surface of SBA-15, and control the temperature, directly on the inner surface of SBA-15 Synthesis containing 1-methyl-3-butyl imidazolium chloride salt. The content of 1-methyl 3-butyl imidazolium chloride was measured by thermogravimetry, and the SBA-15 loaded with the acidic chloroaluminate ionic liquid could be obtained after being treated with aluminum chloride. The specific method is as follows: Weigh 5g of SBA-15 into a 250ml three-neck flask, add 50ml of ethyl acetate, stir magnetically, add 4.1g (0.05mol) of methylimidazole, heat to 80-85°C, and stir for 2 ~3 hours. After that, 4.63 g (0.05 mol) of n-chlorobutane was added and reacted for 48 h under nitrogen atmosphere. After the reaction, the excess ethyl acetate was evaporated, washed three times with ether, and dried in vacuum at 8...

Embodiment 2

[0036]According to the method of Example 1, corresponding materials were prepared as catalysts for the reaction of cyclohexanone and ethylene glycol ketal. The corresponding catalytic conditions were changed, and the orthogonal test was carried out to obtain the maximum yield of cyclohexanone ethylene glycol of 85.3% under the following conditions. Cyclohexanone (9.3ml): ethylene glycol = 1:1.5, temperature: 120°C-125°C, reaction time: 75min, cyclohexane: 15ml. The catalyst was recycled four times, and the catalytic efficiency decreased from 85.3% to 81.3%, as Figure 7 . The shading rate of the product n D 20 =1.4586 (standard shading rate n D 20 = 1.4583). Infrared analysis of the product as Figure 8 , it can be seen that the hydroxyl peak completely disappears and the carbonyl peak is also very small, while the 1163cm -1 、1103cm -1 There are two large C-O-C absorption peaks, which prove that the obtained product is the cyclohexanone ethylene glycol ketal product w...

Embodiment 3

[0038] According to the method of Example 1, keep other conditions unchanged, change the amount of aluminum chloride, respectively with aluminum chloride: 1-methyl-3-butyl imidazolium salt=1:1,1.5:1,2:1, 3:1 (molar ratio) of aluminum chloride to treat the intermediate product A. The obtained catalysts were named as C1, C2, C3, and C4, respectively. And use these catalysts to catalyze the reaction of cyclohexanone and ethylene glycol ketal, the conditions are the same as in Example 2. The result is as Figure 9 , proving that the maximum catalytic effect can be achieved when aluminum chloride: 1-methyl-3-butyl imidazolium salt = 2:1, and the conversion rate of cyclohexanone increases little if the amount of aluminum chloride continues to increase.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com