Method for industrially producing sec-butyl lithium

A technology of sec-butyllithium and lithium particles, which is applied in the field of industrialized production of sec-butyllithium, can solve the problems of reduced quality and yield of sec-butyllithium, flammability and explosion of metal lithium, and easy residual white oil in products, and achieves The effect of shortening the production cycle, no white oil residue, and suppressing side reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

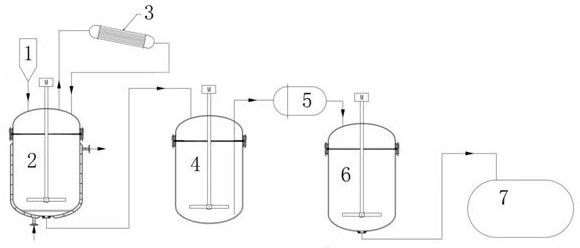

Image

Examples

Embodiment 1

[0040] Dry clean 2000L reactor charge argon gas for 3 times, add 1000L cyclohexane solvent. 60kg of lithium particles are putter into the feeder, and the air is placed 2 times, and the lithium particles are placed in the reactor. The reactor was stirred, and 225 l 2-chlorobutane was added dropwise to the argon atmosphere of 0 to 0.05 MPa, and the completion of 2 h was added. The reaction is released, the temperature is raised to 30 ° C, and the reactor jacket and the reflow condenser are cooled to cool the oil, and the temperature control temperature is 30 to 40 ° C. The dropping end, 30 to 40 ° C insulation reaction for 3 h, and the reaction was pressed into the intermediate tank after the reaction was completed. The material of the intermediate tank was pressed into the filter with argon to remove the lithium chloride solid, 100 L cyclohexane washing the filter residue, resulting in a cyclohexane solution of 1200L pale yellow transparent sec-butyllithium, concentration: 14.0%, a...

Embodiment 2

[0042]700L cyclohexane solvent was added to the 2000L reactor. 32kg lithium particles are puttering the feeder, and the air is discharged from the gas. The lithium particles are placed in the reactor. The reactor was stirred, and 225 l 2-chlorobutane was added dropwise to the argon atmosphere of 0 to 0.05 MPa, and the completion of about 3 h hetero. The reaction is released, the temperature is raised to 30 ° C, and the reactor jacket and the reflow condenser are cooled to cool the oil, and the temperature control temperature is 30 to 40 ° C. The dropping end, the reaction was held at 30 to 40 ° C for 2 h, and after the reaction was completed, the reaction mixture was pressed into the intermediate can. Pressure of the bottle in the intermediate tank to remove the silicon chloride solid, 100L cyclohexane washing filter residue with argon, to give 900L pale-yellow transparent sec-butyristyl cyclohexane solution, concentration: 18.5%, activity: 98.7% , Oxine: 0.16%, covalent chlorine:...

Embodiment 3

[0044] 800L n-hexane solvent was added to the 2000L reactor. 30 kg of lithium particles are puttering the feeder, and the air is discharged from the air 3 times, and then the lithium particles are placed in the reaction kettle. The reactor was stirred, and 225 l 2-chlorobutane was added dropwise to the argon atmosphere of 0 to 0.05 MPa, and the completion of 2 h was added. The reaction is released, the temperature is raised to 30 ° C, and the reactor jacket and the reflow condenser are cooled to cool the oil, and the temperature control temperature is 30 to 40 ° C. End of dropwise, at 3 0 to 40 ° C for 2 h, and after the reaction was completed, the reaction mixture was pressed into the intermediate can. The material of the intermediate tank was pressed into the filter with argon to remove the lithium chloride solid, 100 L n-hexane washing filter residue, obtained 1000 L of colorless and transparent sec-butyristyl, concentration of 18.6%, activity: 98.4%, butter : 0.20%, covalent c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com