Medicinal butyl chloride rubber plug and production technology thereof

A technology of chlorinated butyl rubber stoppers and chlorinated butyl rubber, which is applied in the field of medicinal chlorinated butyl rubber stoppers and its production process, and can solve problems such as high mechanical strength, easy scorching, and bubbling on the surface of rubber stoppers , to achieve the effect of reducing the defective rate, strong adsorption performance, and improving the problem of bubbling bubbles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

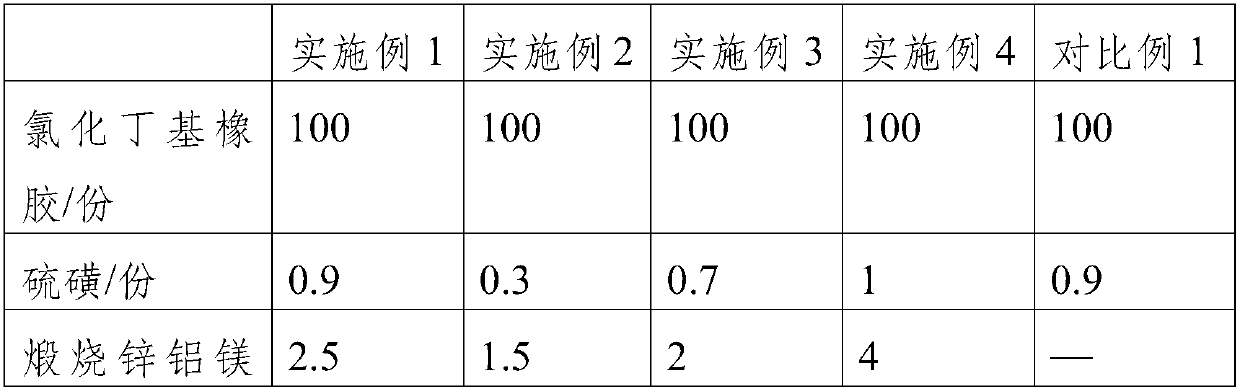

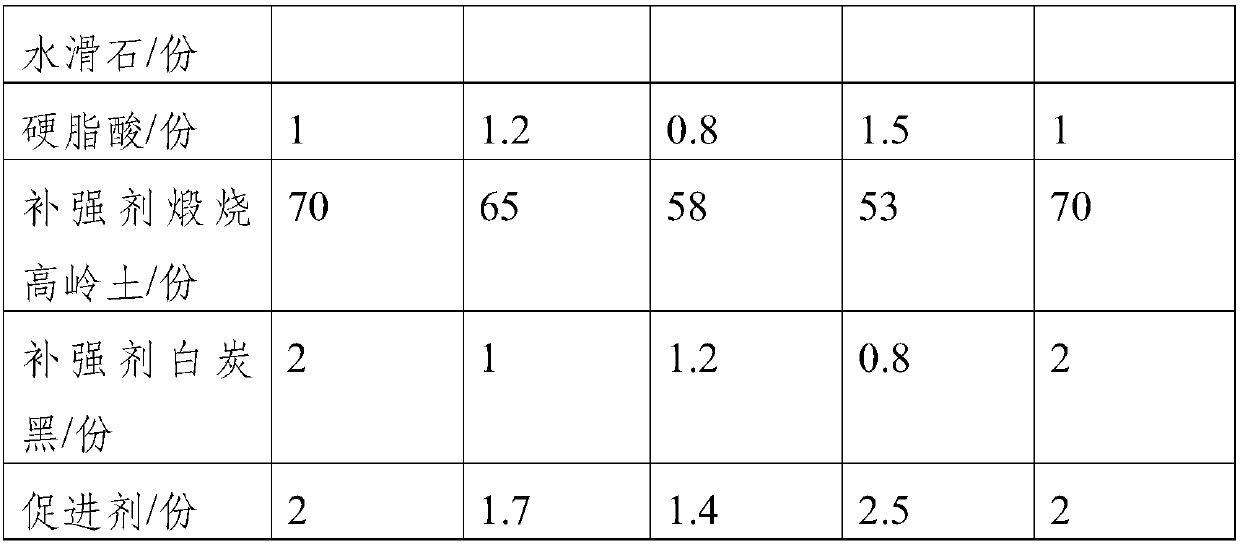

Embodiment 1-4

[0022] Examples 1-4 The composition of the raw materials for medicinal chlorobutyl rubber stoppers includes zinc-aluminum-magnesium hydrotalcite calcined at 350°C for 4 hours. The preparation process of zinc-aluminum-magnesium hydrotalcite is: dissolving magnesium chloride hydrate, zinc chloride and aluminum chloride hydrate in ultrapure water, stirring and dissolving to obtain a mixed salt solution, adding sodium hydroxide and sodium carbonate solution dropwise to the mixed salt solution To obtain a mixed reaction solution, add the mixed reaction solution dropwise to a reaction vessel kept at 50°C, and continue to stir. After the dropwise addition, use 1mol / L sodium hydroxide solution to adjust the pH value of the system to 11, continue to keep warm for 30min, and centrifuge The precipitate was obtained, and then the precipitate was redispersed into ultrapure water, reacted at 120°C for 24 hours, cooled, filtered with suction, washed the filter cake with water, dried, and grou...

Embodiment 5

[0028] Embodiments 5-7 are based on Example 1, the difference is that the zinc-containing magnesium-based hydrotalcites used in Example 5 are zinc-nickel-magnesium-aluminum quaternary hydrotalcites produced by a steady-state co-precipitation method, and the zinc-nickel-magnesium-aluminum quaternary hydrotalcites The molar ratio of zinc ion, nickel ion, magnesium ion and chloride ion in hydrotalcite is 1:1.05:1:1; Accelerator adopts dibenzothiazole disulfide in embodiment 6; Adopt p-tert-butyl Phenol disulfide replaces sulfur as the vulcanizing agent.

Embodiment 8

[0030] Example 8 is based on Example 1, and the difference is that it also includes a silane coupling agent KH-570, and the number of parts by weight of the silane coupling agent is 2 parts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com