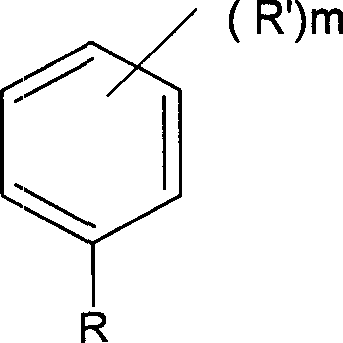

Manufacturing method of alkyl benzene solvent and its application

A technology of alkylbenzene and solvent, which is applied in the field of preparation of alkylbenzene solvent, can solve the problems of isobutylene storage, inconvenient transportation, low chemical stability of solvent, low purity of alkylbenzene solvent, etc., and achieve shortened reaction time, High reactant selectivity and environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) raw material: o-xylene 160Kg, purity is 99%, water content is 20ppm;

[0030] 140Kg of tert-butyl chloride, the purity is 99%, and the water content is 300ppm;

[0031] Catalyst: 1.65Kg of triethylamine hydrochloride, 3.3Kg of anhydrous aluminum trichloride.

[0032] (2) Preparation process

[0033] Put 160Kg of o-xylene, 3.3Kg of anhydrous aluminum trichloride, and 1.65Kg of triethylamine hydrochloride into the reaction kettle in turn, start stirring, add 140Kg of tert-butyl chloride, control the temperature at 20°C, and stir at constant temperature for 4 Hour. Follow up and analyze with gas chromatography according to the conventional method, stop stirring when reaching the end of the reaction, and separate the catalyst in the lower layer for future use. The reaction solution was washed with alkali and water according to the conventional method, and after the treatment, it was distilled under reduced pressure, and the fraction at 138-140°C was...

Embodiment 2

[0039] (1) Raw material: ethylbenzene 167.4Kg, purity is 95%, water content is 100ppm;

[0040] Tert-butyl chloride 94.4Kg, purity 99%, water content 1000ppm;

[0041] Catalyst: 0.48Kg of tetrabutylammonium bromide, 0.83Kg of anhydrous aluminum trichloride.

[0042] (2) Preparation process

[0043] Add 167.4Kg of ethylbenzene, 0.83Kg of anhydrous aluminum trichloride, and 0.48Kg of tetrabutylammonium bromide into the reaction kettle in turn, start stirring, add 94.4Kg of tert-butyl chloride, control the temperature at 0°C, and stir at a constant temperature for 5 Hours. Follow up the analysis with gas chromatography according to the conventional method, and stop stirring at the end of the reaction. The reaction solution was washed with alkali and water according to the conventional method, and after the treatment, it was distilled under reduced pressure, and the fraction at 138-140°C was collected at 10Kpa to obtain 150Kg of alkylbenzene solvent with a pur...

Embodiment 3

[0045] Raw materials: m-xylene 106.5Kg, purity 99.5%, water content 30ppm; tert-butyl chloride 144.6Kg, purity 97%, water content 100ppm; catalyst: cetyltrimethylammonium bromide 23.4Kg, no Aluminum trichloride water 26.8Kg.

[0046] Reaction temperature is 5 ℃, all the other are the same as embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Water content | aaaaa | aaaaa |

| Water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com