Method for preparing tert-butyldimethyl chlorosilane

A technology of tert-butyldimethylchlorosilane and cyclohexane, which is applied in the field of preparation of tert-butyldimethylchlorosilane, can solve the problems of solvent loss, incomplete dehydration of filter cake, decomposition and disproportionation of chlorosilane, etc. Achieve the effects of easy control, stable product yield and simple production operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

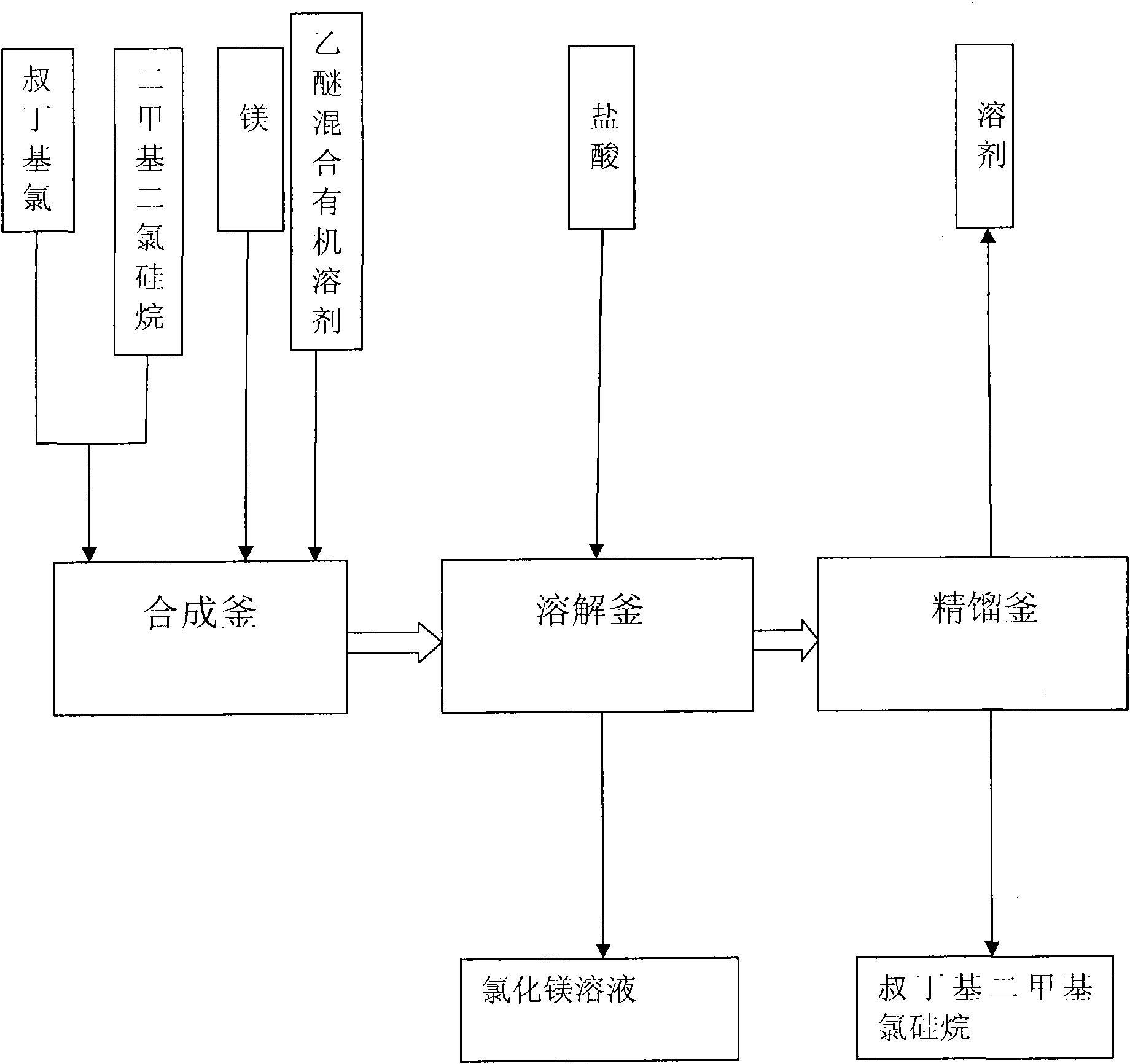

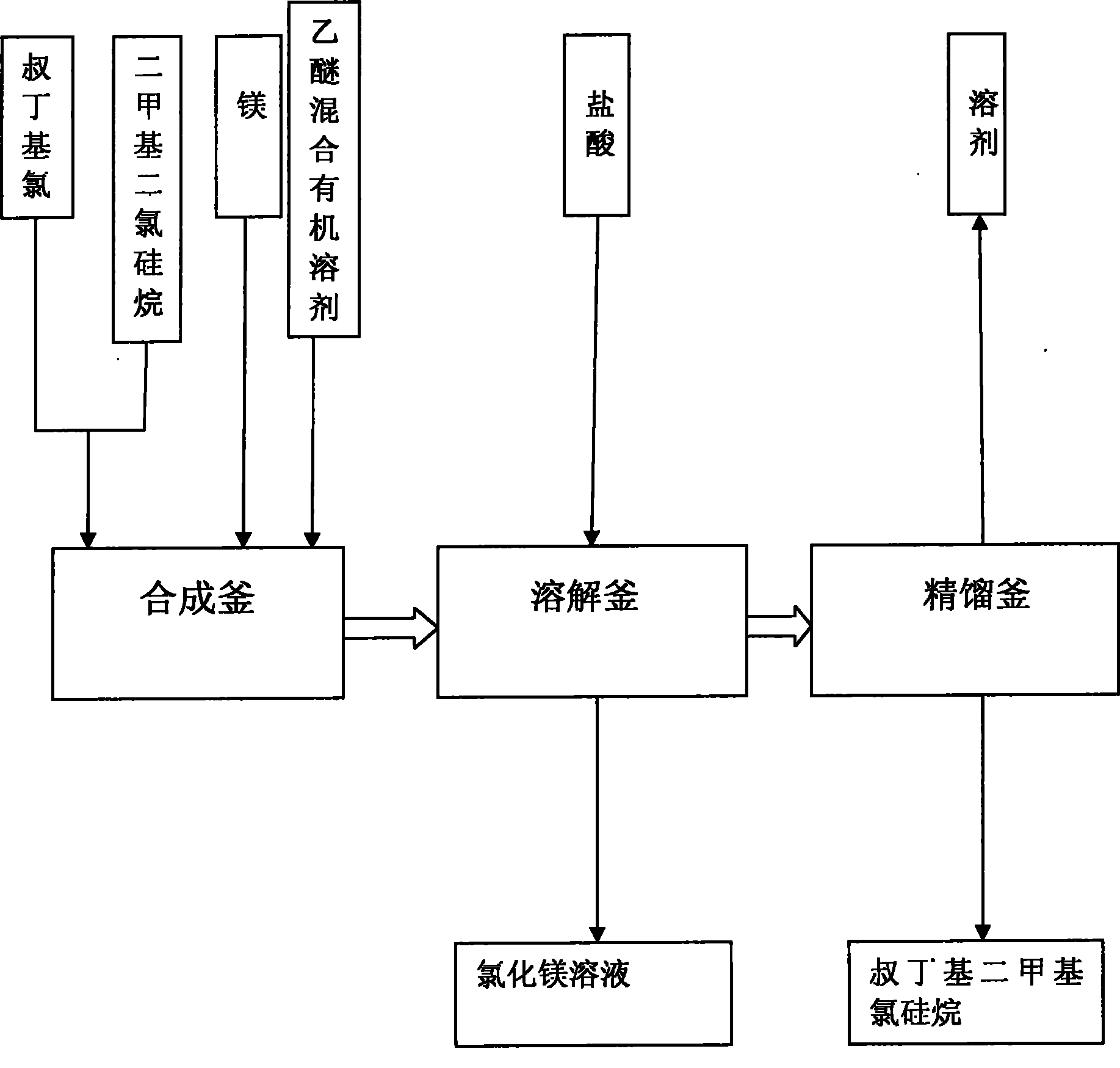

[0021] like figure 1 Shown, a kind of preparation method of tert-butyldimethylsilyl chloride,

[0022] a. In the synthesis kettle, put 10g of magnesium into a mixed solvent of 160ml of ether and cyclohexane, the volume ratio of ether and cyclohexane in the mixed solvent is 6.5:3.5, drop Add a mixed solution composed of 35g tert-butyl chloride and 50g dimethyldichlorosilane, and keep it warm for 2.5 hours after dropping to obtain the synthesized material;

[0023] b. Transfer the synthesized material into the dissolution tank, drop the temperature to 10°C and add 400ml of hydrochloric acid with a volume concentration of 25%, static layering, remove the waste water at the bottom, and obtain the upper layer of material liquid;

[0024] c. Transfer the upper layer material liquid in the dissolving tank to the rectifying tank for purification, remove the solvent, and obtain the product tert-butyldimethylchlorosilane.

Embodiment 2

[0026] like figure 1 Shown, a kind of preparation method of tert-butyldimethylsilyl chloride,

[0027] a. In the synthesis kettle, put 12g of magnesium into a mixed solvent composed of 200ml of ether and cyclohexane. The volume ratio of ether and cyclohexane in the mixed solvent is 7:3. At 50°C, add dropwise A mixed solution composed of 45g tert-butyl chloride and 65g dimethyldichlorosilane was incubated for 3 hours after dropping to obtain the synthesized material;

[0028] b. Transfer the synthesized material into the dissolution tank, drop the temperature to 12.5°C and add 500ml of hydrochloric acid with a volume concentration of 28%, static layering, remove the waste water at the bottom, and obtain the upper layer of feed liquid;

[0029] c. Transfer the upper layer material liquid in the dissolving tank to the rectifying tank for purification, remove the solvent, and obtain the product tert-butyldimethylchlorosilane.

Embodiment 3

[0031] like figure 1 Shown, a kind of preparation method of tert-butyldimethylsilyl chloride,

[0032] a. In the synthesis kettle, put 15g of magnesium into a mixed solvent of 240ml of ether and cyclohexane. The volume ratio of ether and cyclohexane in the mixed solvent is 7.5:2.5. At 55°C, add dropwise A mixed solution composed of 55g tert-butyl chloride and 78g dimethyldichlorosilane was incubated for 3.5 hours after dropping to obtain the synthesized material;

[0033] b. Transfer the synthesized material into the dissolution tank, drop the temperature to 15°C, add 600ml of hydrochloric acid with a volume concentration of 30%, static layering, remove the waste water at the bottom, and obtain the upper layer of material liquid;

[0034] c. Transfer the upper layer material liquid in the dissolving tank to the rectifying tank for purification, remove the solvent, and obtain the product tert-butyldimethylchlorosilane.

[0035] The invention has the advantages that the produc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com