Calcium silicate hydrate nano coating and its production method

A technology of hydrated calcium silicate and hydrated calcium silicate powder, applied in the coating and other directions, can solve the problems of high price of advanced coatings, inability to popularize and apply in a large area, etc. Application-wide effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

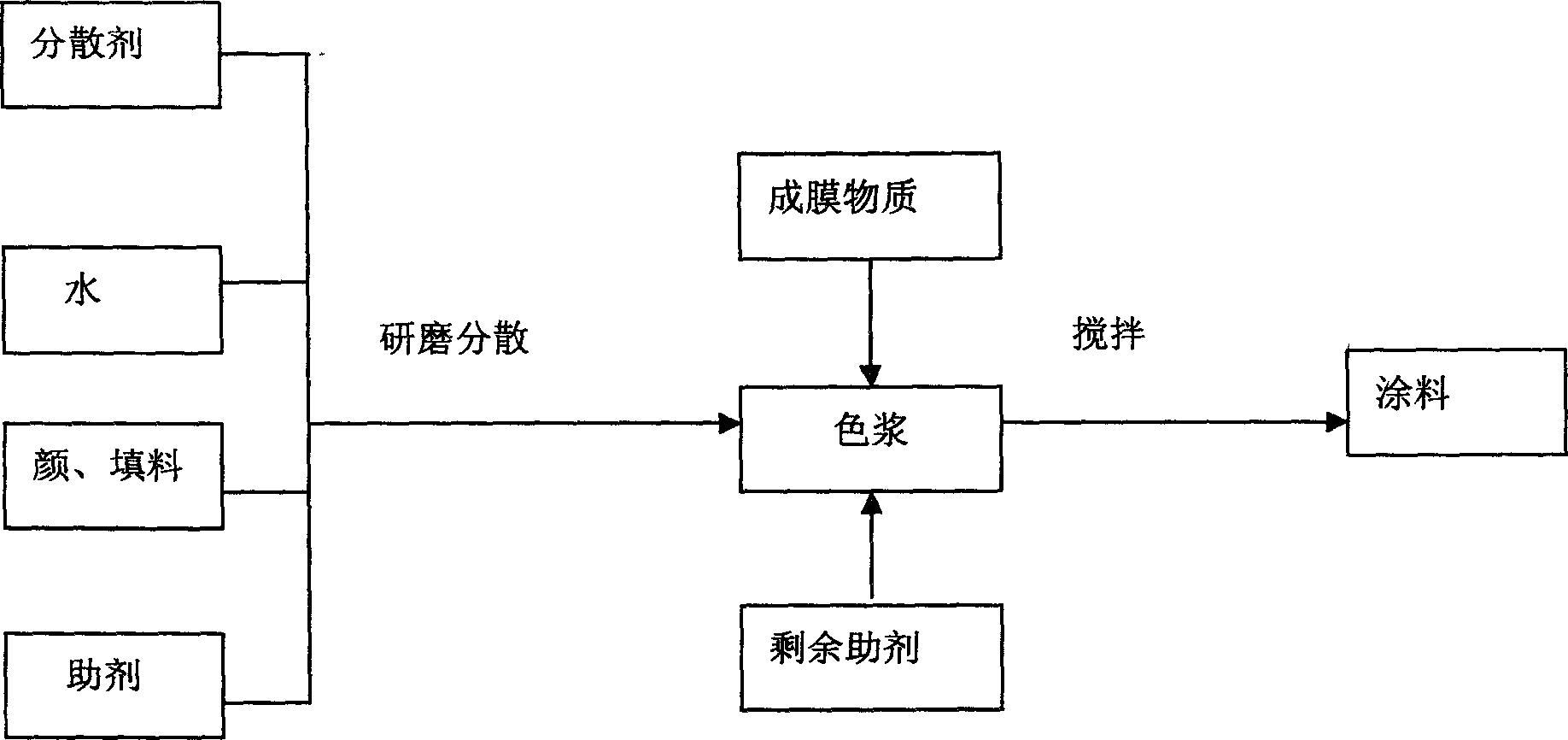

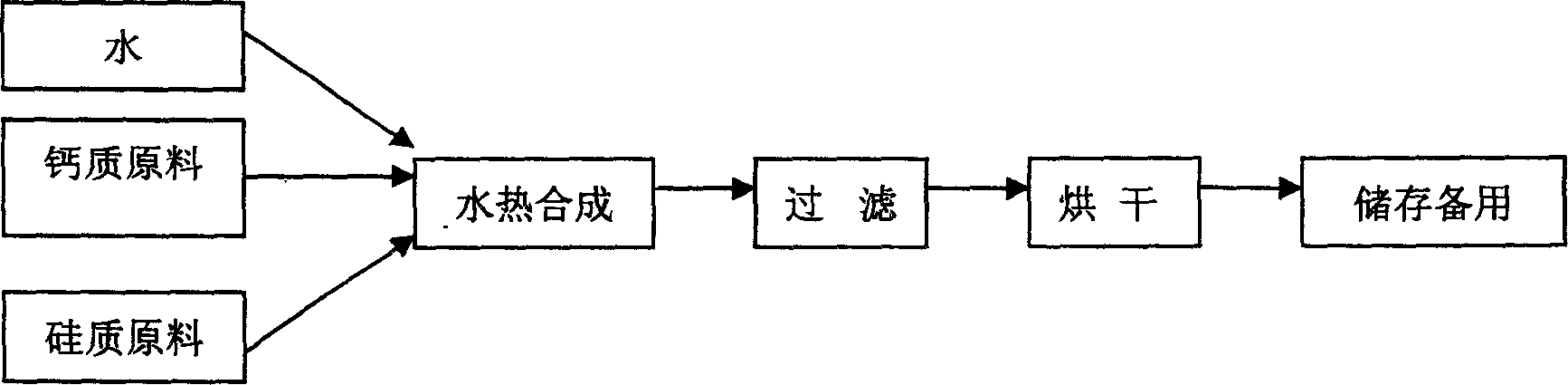

Method used

Image

Examples

Embodiment 1

[0042] Embodiment one: the calcium silicate hydrate nano coating of the present invention contains the following components calculated by mass percentage:

[0043] Acrylic film-forming emulsion: any value between 37.0 and 39.0%;

[0044] Pigment: any value between 5.07% and 6.20%;

[0045] Talc powder: any value between 6.50% and 7.50%;

[0046] Calcium silicate hydrate powder: any value between 10.5% and 11.0%;

[0047] Coalescing aids: Any value between 0.38% and 0.88%;

[0048] Defoamer: any value between 0.4% and 0.9%;

[0049] Water: any value between 34.52% and 40.5%.

[0050] The above-mentioned acrylic film-forming emulsion can be pure acrylic emulsion, styrene-acrylic emulsion or silicone-acrylic emulsion. This ratio uses pure acrylic emulsion, for example: XG-2002 construction emulsion adhesive.

[0051] In addition to the above components, the paint can also contain 0-3% dispersant, and the dispersant can be selected from sodium hexametaphosphate or sodium pol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com