Remote procedure call (RPC) design-based inorganic synthetic quartz plate and preparation technology thereof

A quartz plate, artificial technology, applied in the field of building decoration materials, to improve construction performance, improve performance, improve decorative effect and sensory comfort.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

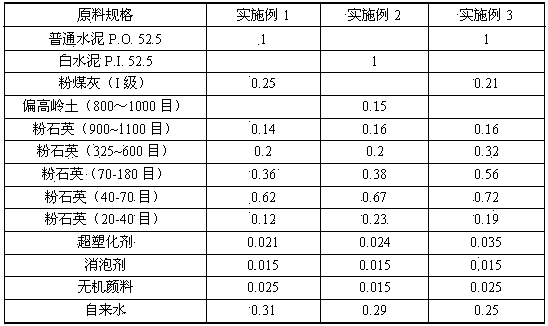

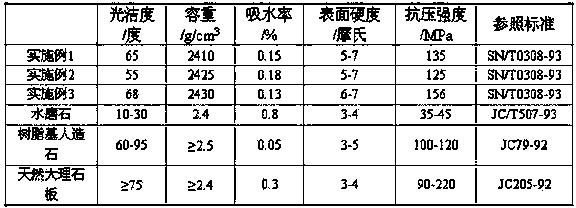

Examples

preparation example Construction

[0041] The preparation technology of the inorganic artificial quartz plate based on RPC design comprises the following steps:

[0042] a. Weigh each raw material according to the above ratio, dry mix for 1~2min; add 3 / 4 of the mixing water dissolved in superplasticizer, forcefully stir for 1~2min, add the rest, and continue to stir until slurry; according to the ratio Add the required steel fiber and continue to stir to ensure that it is evenly dispersed in the slurry; dissolve the defoamer in water according to the ratio of water: defoamer = 3:1, add the slurry and continue to stir for 1 to 2 minutes; finally add the Inorganic pigments are required, stirred for 2-3 minutes, and then poured; 1-2 hours after the pouring is completed, the grid cloth is spread;

[0043] b. Curing: standard curing for 24-48 hours (RH>90%, 20°C); after demolding, hydrothermal curing for 24-48 hours (80-95°C), or autoclaving for 8-12 hours (160-230°C), and then Standard breeding to 7~28d;

...

Embodiment 1

[0047] The preparation process of the plate is carried out according to the following steps:

[0048] a. Weigh each raw material according to the proportion, dry mix for 1~2min; add 3 / 4 of the mixing water dissolved in superplasticizer, forcefully stir for 1~2min, add the rest, and continue to stir until slurry; add the required Steel fiber, continue to stir for 3 to 5 minutes to ensure that it is evenly dispersed in the slurry; dissolve the defoamer (water: defoamer = 3:1) in an appropriate amount of water, add the slurry and continue to stir for 1 to 2 minutes; finally add the Inorganic pigments are required, stir for 2-3 minutes, and pour. The grid cloth can be paved 1-2 hours after the pouring is completed, and multiple layers can also be paved during the pouring process, which should be selected according to the performance and thickness of the board.

[0049] c. Curing: standard cultivation for 48 hours (RH>90%, 20°C); after demolding, hydrothermal curing for 48 hours (...

Embodiment 2

[0053] The specific implementation process is the same as in Example 1, the difference being that the used mix ratio is different, and the cement used is white Portland cement.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com