Nano silicon thermal insulation material and preparation method thereof

A thermal insulation material, nano-silicon technology, applied in chemical instruments and methods, layered products, ceramic layered products, etc., can solve the problems of inability to guarantee strength, affecting the use effect, and increasing thermal conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

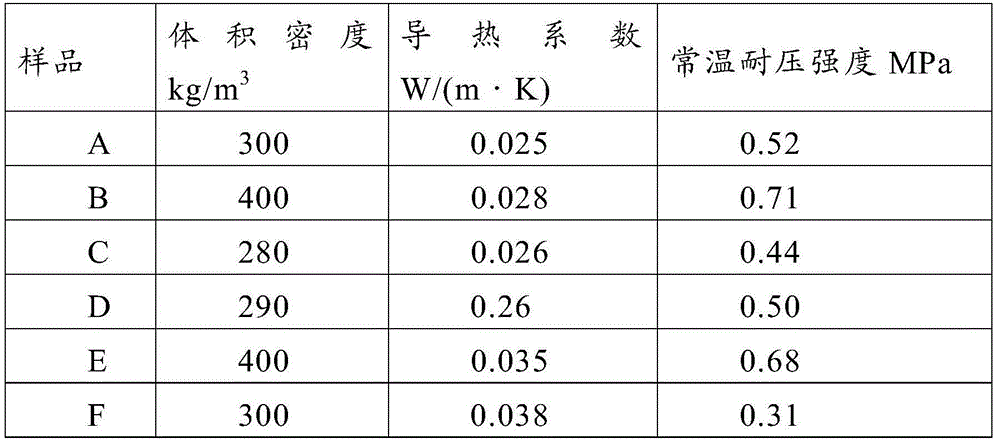

Examples

preparation example Construction

[0040] The invention also discloses a preparation method of nano silicon heat insulating material, comprising the following steps:

[0041] (A) uniformly mixing 60-80 parts by weight of nano silicon dioxide, 5-15 parts by weight of inorganic fibers and 15-35 parts of carbon black to obtain the first mixture;

[0042] Mix 60-80 parts by weight of nano silicon dioxide, 5-15 parts by weight of inorganic fibers and 15-35 parts of infrared light-shielding agent to obtain the second mixture; the infrared light-shielding agent is titanium dioxide, zirconium oxide, silicon carbide and hexatanium One or more of potassium phosphate whiskers;

[0043] (B) Put any one of the first mixture and the second mixture into the mold and scrape it, and then spread another mixture on the surface and scrape it, and then press to obtain the nano silicon heat insulating material.

[0044] The invention uses one or more of nano silicon dioxide, inorganic fiber, carbon black and titanium dioxide, zirco...

Embodiment 1

[0054] Weigh 60 parts by weight of nano-silica, 10 parts by weight of alkali-free glass fiber, and 30 parts by weight of carbon black, and slowly add each raw material into the nano-coating machine at the same time. After premixing at a low speed of 200rpm for 4 minutes, raise the rotor Rotate to 1000rpm, stir for 20min, after stirring, take out the material, and weigh 120g of the material into the mold as the bottom layer, use a scraper to scrape it; then weigh 60 parts by weight of nano-silica, 15 parts by weight of alkali-free Glass fiber, 25 parts by weight of silicon carbide, slowly add each raw material into the nano-coating machine at the same time, use the same mixing process to mix evenly, take out the material, weigh 120g of the material and spread it on the bottom material in the mold , use a scraper to scrape it flat, and then use a press with a pressure of 3.0MPa to compress the material to a thickness of 20mm and keep the pressure for 10min, and then demould to ob...

Embodiment 2

[0056] Weigh 75 parts by weight of nano-silica, 10 parts by weight of alumina fiber, and 15 parts by weight of carbon black, and slowly add each raw material into the nano-coating machine at the same time. After premixing at a low speed of 300 rpm for 4 minutes, increase the rotor speed of the nano-coating machine to 1200rpm, stirred for 15min, after the stirring was completed, the material was taken out, and 160g of the material was weighed and put into the mold as the bottom layer, and scraped with a scraper; then weighed 70 parts by weight of nano-silica, 15 parts by weight of alumina fiber 15 parts by weight of potassium hexatitanate whiskers, slowly add each raw material into the nano-coating machine at the same time, use the same mixing process to mix evenly, take out the material, and weigh 160g of the material and spread it on the bottom layer of the mold Use a scraper to scrape the top of the material flat, and then use a press with a pressure of 4.0MPa to compress the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com