Power cable for solar photovoltaic power distribution cabinet

A solar photovoltaic and power cable technology, which is applied in the manufacture of power cables, insulated cables, cables/conductors, etc., can solve problems such as the inability to meet the special requirements of photovoltaic power distribution cabinets, and achieve soft texture, superior flame retardancy, and improved performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

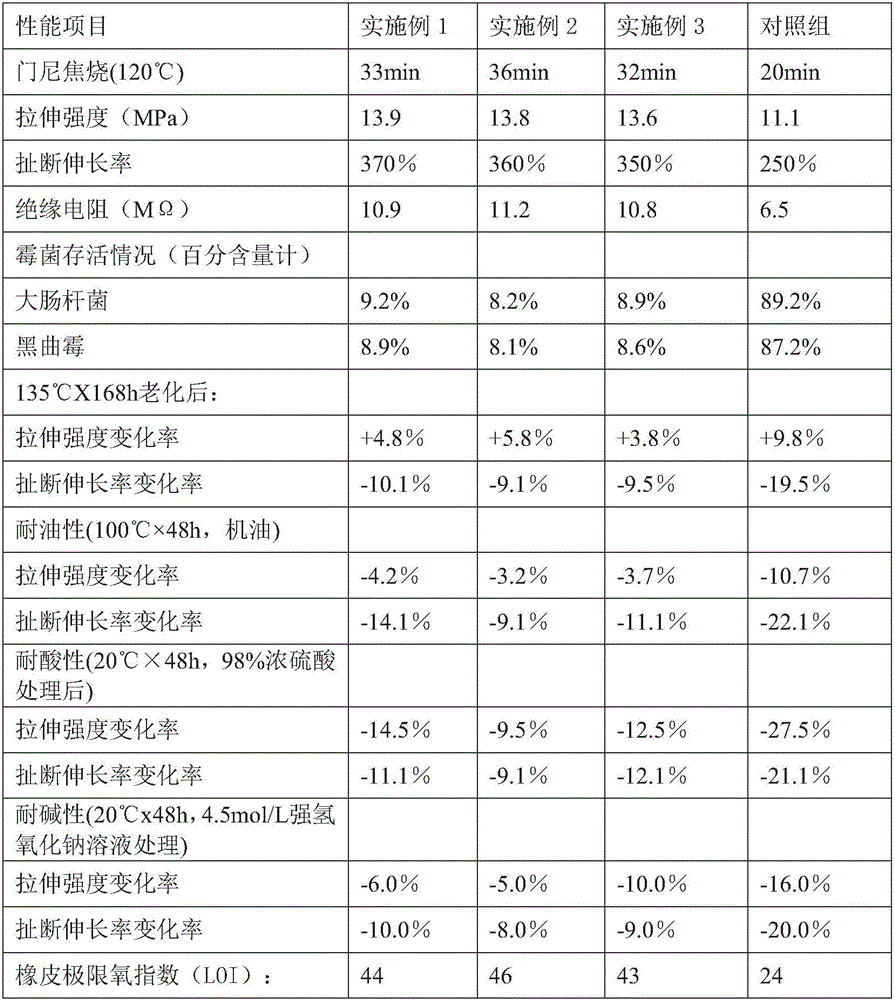

Examples

Embodiment 1

[0017] The power cable for the solar photovoltaic power distribution cabinet in this embodiment includes a plurality of copper alloy wires and protective sleeves. The copper alloy wires are placed in parallel with each other, and the outer layer of each copper alloy wire is covered with a protective sleeve. The protective sleeve is made of The following components are composed of parts by mass: 26 parts of acrylate rubber powder, 24 parts of SEBS thermoplastic elastomer, 24 parts of styrene-modified alkyd resin, 22 parts of waste oil, 24 parts of tricaprylin, 24 parts of sandalwood oil, 22 parts of styrene-acrylic emulsion, 24 parts of transformer oil, 24 parts of benzalkonium chloride, 22 parts of dibenzofuran, 22 parts of zinc pyrithione, 22 parts of bisimidazolidinyl urea, 24 parts of lead oxide powder, 22 parts of fly ash parts, 20 parts of antimony oxide powder, 24 parts of sodium iodoacetate, 22 parts of potassium fluorotitanate, 20 parts of pearl powder, 22 parts of mica...

Embodiment 2

[0024]The power cable for the solar photovoltaic power distribution cabinet in this embodiment includes a plurality of copper alloy wires and protective sleeves. The copper alloy wires are placed in parallel with each other, and the outer layer of each copper alloy wire is covered with a protective sleeve. The protective sleeve is made of The following components are composed of parts by mass: 28 parts of acrylate rubber powder, 26 parts of SEBS thermoplastic elastomer, 26 parts of styrene-modified alkyd resin, 24 parts of waste oil, 26 parts of tricaprylin, 26 parts of sandalwood oil, 24 parts of styrene-acrylic emulsion, 26 parts of transformer oil, 26 parts of benzalkonium chloride, 24 parts of dibenzofuran, 24 parts of zinc pyrithione, 24 parts of bisimidazolidinyl urea, 26 parts of lead oxide powder, 24 parts of fly ash parts, 22 parts of antimony oxide powder, 26 parts of sodium iodoacetate, 24 parts of potassium fluorotitanate, 22 parts of pearl powder, 24 parts of mica ...

Embodiment 3

[0031] The power cable for the solar photovoltaic power distribution cabinet in this embodiment includes a plurality of copper alloy wires and protective sleeves. The copper alloy wires are placed in parallel with each other, and the outer layer of each copper alloy wire is covered with a protective sleeve. The protective sleeve is made of The following components are composed of parts by mass: 30 parts of acrylate rubber powder, 28 parts of SEBS thermoplastic elastomer, 28 parts of styrene-modified alkyd resin, 26 parts of waste oil, 28 parts of tricaprylin, 28 parts of sandalwood oil, 26 parts of styrene-acrylic emulsion, 28 parts of transformer oil, 28 parts of benzalkonium chloride, 26 parts of dibenzofuran, 26 parts of zinc pyrithione, 26 parts of bisimidazolidinyl urea, 28 parts of lead oxide powder, 26 parts of fly ash parts, 24 parts of antimony oxide powder, 28 parts of sodium iodoacetate, 26 parts of potassium fluorotitanate, 24 parts of pearl powder, 26 parts of mica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com