Environmental-friendly protection coating of art design printed wrapping paper

A technology of printing, packaging and protective coating, which is applied in the direction of wrapping paper, wrapping paper, coating, etc., can solve the problems of not having anti-mildew and anti-bacterial functions, and can not meet the storage requirements of paper, etc., to achieve superior flame retardancy and improve product performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

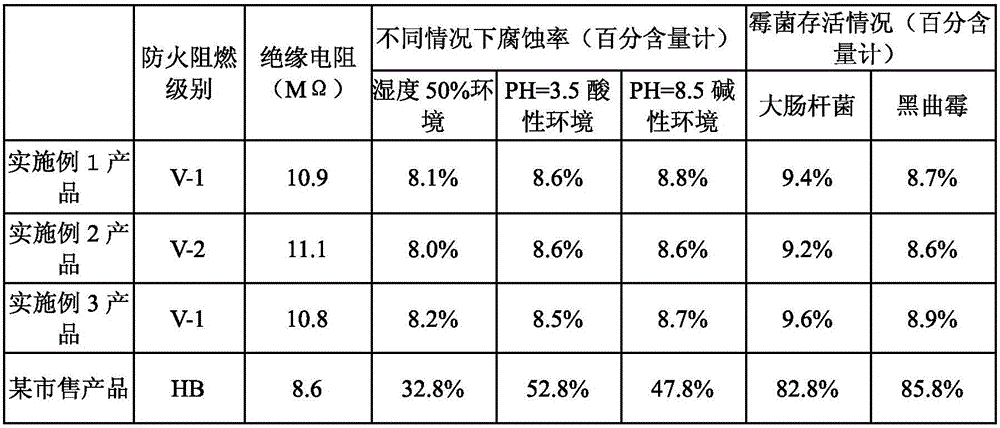

Examples

Embodiment 1

[0016] The environmental protection coating of art design printing wrapping paper in the present embodiment is made up of the following components of mass fraction: 18 parts of trioctyl trimellitate, 16 parts of hydrogenated rosin, 16 parts of heat vulcanized silicone rubber, triethylene glycol 14 parts of diisocaprylate, 16 parts of cellulose acetate butyrate, 16 parts of dibasic lead stearate, 14 parts of ammonium polyphosphate, 16 parts of calcium hypochlorite, 16 parts of methyl p-hydroxybenzoate, 14 parts of Bacendazim, 14 parts of Didecyl Dimethyl Ammonium Chloride, 14 parts of Sodium Dichloroisocyanurate, 16 parts of Sodium Hydrosulfide, 14 parts of Calcium Acetate, 12 parts of Disodium Hydrogen Phosphate, 16 parts of Soda Ash, 14 parts of praseodymium powder, 12 parts of dolomite powder, 14 parts of honey, 12 parts of lavender essential oil, 12 parts of cottonseed oil, 14 parts of sandalwood oil, 14 parts of styrene-acrylic emulsion, 14 parts of propoxylated neopentyl g...

Embodiment 2

[0022] The environmental protection coating of art design printing wrapping paper in the present embodiment is made up of the component of following mass fraction: 20 parts of trioctyl trimellitate, 18 parts of hydrogenated rosin, 18 parts of heat vulcanized silicone rubber, triethylene glycol 16 parts of diisocaprylate, 18 parts of cellulose acetate butyrate, 18 parts of dibasic lead stearate, 16 parts of ammonium polyphosphate, 18 parts of calcium hypochlorite, 18 parts of methyl p-hydroxybenzoate, 16 parts of Bacillin, 16 parts of Didecyl Dimethyl Ammonium Chloride, 16 parts of Sodium Dichloroisocyanurate, 18 parts of Sodium Hydrosulfide, 16 parts of Calcium Acetate, 14 parts of Disodium Hydrogen Phosphate, 18 parts of Soda Ash, 16 parts of praseodymium powder, 14 parts of dolomite powder, 16 parts of honey, 14 parts of lavender essential oil, 14 parts of cottonseed oil, 16 parts of sandalwood oil, 16 parts of styrene-acrylic emulsion, 16 parts of propoxylated neopentyl glyc...

Embodiment 3

[0028] The environmental protection coating of artistic design printing wrapping paper in the present embodiment is made up of the component of following mass fraction: 22 parts of trioctyl trimellitate, 20 parts of hydrogenated rosin, 20 parts of heat vulcanized silicone rubber, triethylene glycol 18 parts of diisocaprylate, 20 parts of cellulose acetate butyrate, 20 parts of dibasic lead stearate, 18 parts of ammonium polyphosphate, 20 parts of calcium hypochlorite, 20 parts of methyl p-hydroxybenzoate, 18 parts of Bacillin, 18 parts of Didecyl Dimethyl Ammonium Chloride, 18 parts of Sodium Dichloroisocyanurate, 20 parts of Sodium Hydrosulfide, 18 parts of Calcium Acetate, 16 parts of Disodium Hydrogen Phosphate, 20 parts of Soda Ash, 18 parts of praseodymium powder, 16 parts of dolomite powder, 18 parts of honey, 16 parts of lavender essential oil, 16 parts of cottonseed oil, 18 parts of sandalwood oil, 18 parts of styrene-acrylic emulsion, 18 parts of propoxylated neopentyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com