A lithium ion battery isolation film and a preparation method thereof

A lithium-ion battery and separator technology, applied in battery pack parts, separators/films/diaphragms/spacers, circuits, etc., can solve problems such as high bonding strength and low swelling, and achieve good air permeability , The effect of improving safety performance and battery cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

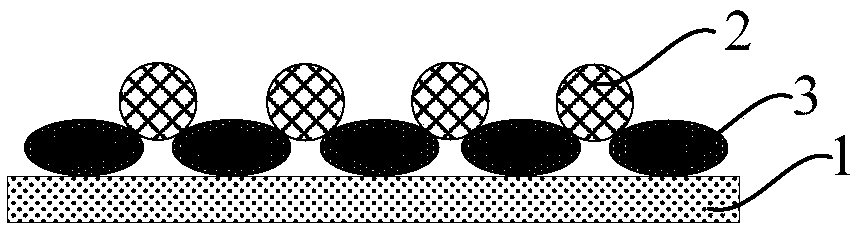

[0066] Such as Figure 8 As shown, the present invention also provides a preparation method of a lithium-ion battery separator, using the preparation method, the above-mentioned lithium-ion battery separator can be prepared, and the preparation method includes:

[0067] S1. Mix the polymer, solvent and additives uniformly to obtain a polymer slurry. The polymer material includes polyacrylic acid, polymethacrylic acid, polymethyl acrylate, polyethyl acrylate, polyacrylic acid-styrene copolymer materials, neopentyl glycol diacrylate, polytetrafluoroethylene, polyimide, polyamides, polyesters, polysulfones, polyacrylonitrile at least one of the group consisting of the polymer pulp The total weight of the material is 100 parts, the weight of the polymer is between 10 and 85 parts, the weight of the solvent is between 10 and 85 parts, and the weight of the auxiliary agent is between 0.01 and 10 parts between;

[0068] S2, providing a porous substrate, coating the polymer slurry o...

Embodiment 2

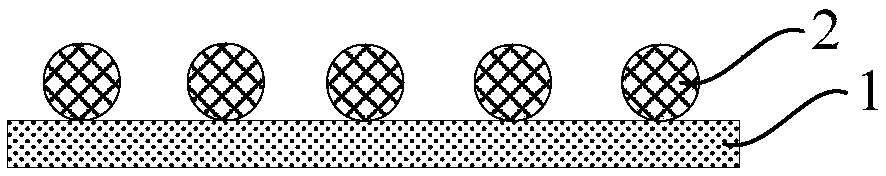

[0096] The polymer slurry was coated on one side of the same PE porous base film as in Comparative Example 1 by gravure coating, and finally baked in an oven to form a thickness of the polymer coating of 0.5 μm. A lithium-ion battery separator formed by a high-viscosity low-swell polymer coating and a PE porous base film can be prepared, with a total thickness of 11.5 μm.

Embodiment 3

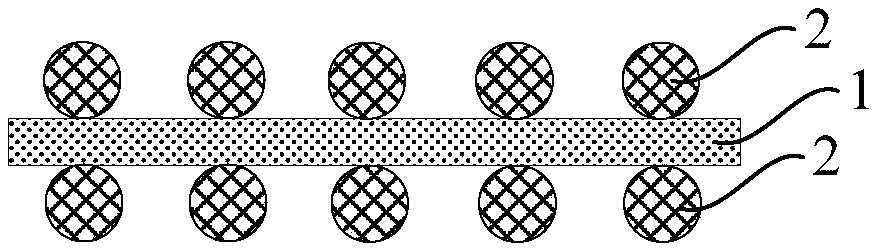

[0104] The polymer slurry was coated on both sides of the same porous substrate as in Comparative Example 2 by gravure coating, and finally the thickness of the polymer coating formed by oven baking was 0.5 μm , Lithium-ion battery separator formed by high-viscosity and high-swell polymer coating and PE microporous base film, with a total thickness of 13 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com