Water-based UV (ultraviolet) coating material

A coating and water-based technology, applied in the field of water-based UV coatings, can solve the problems of poor adhesion and low surface polarity of UV coatings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

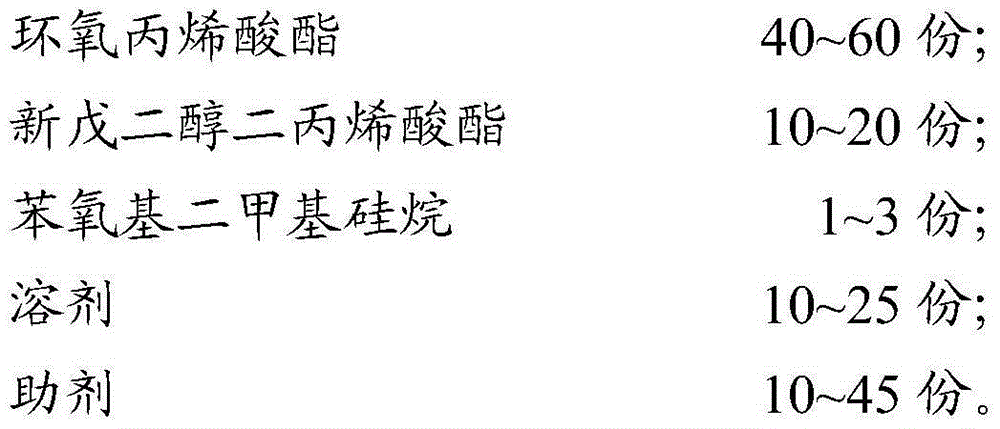

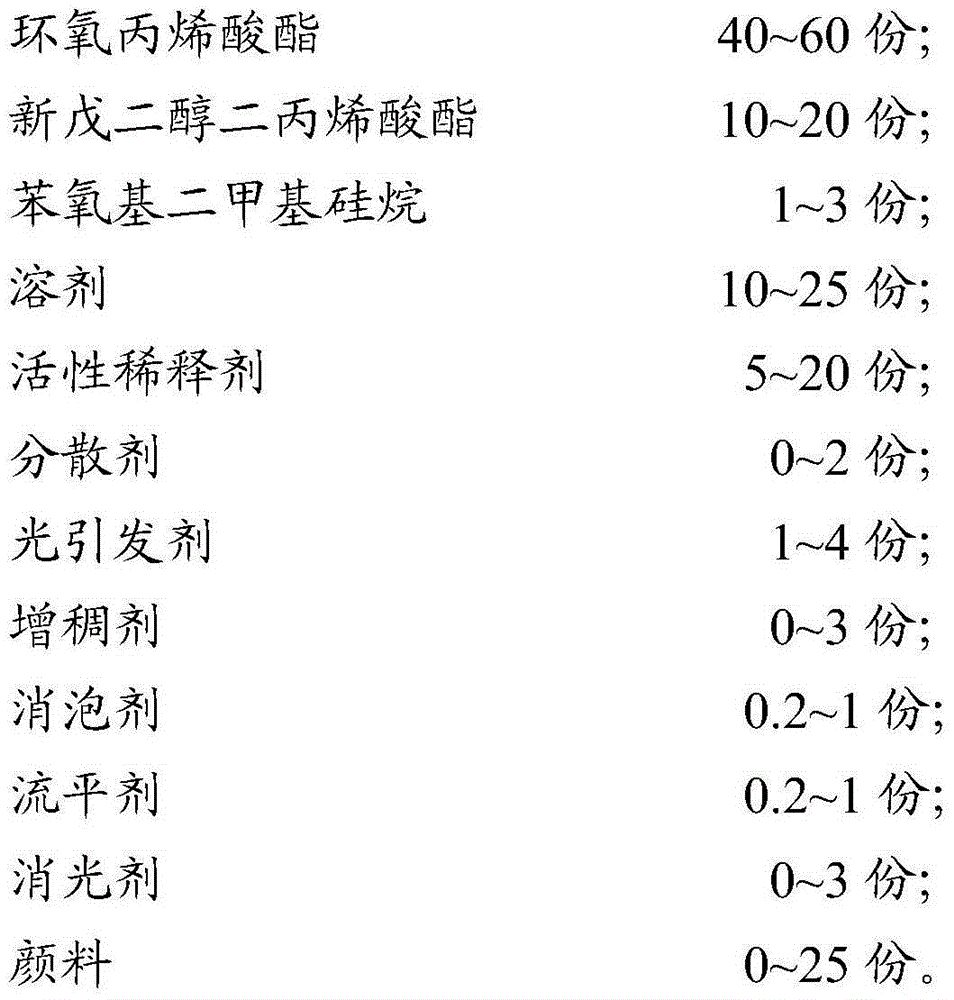

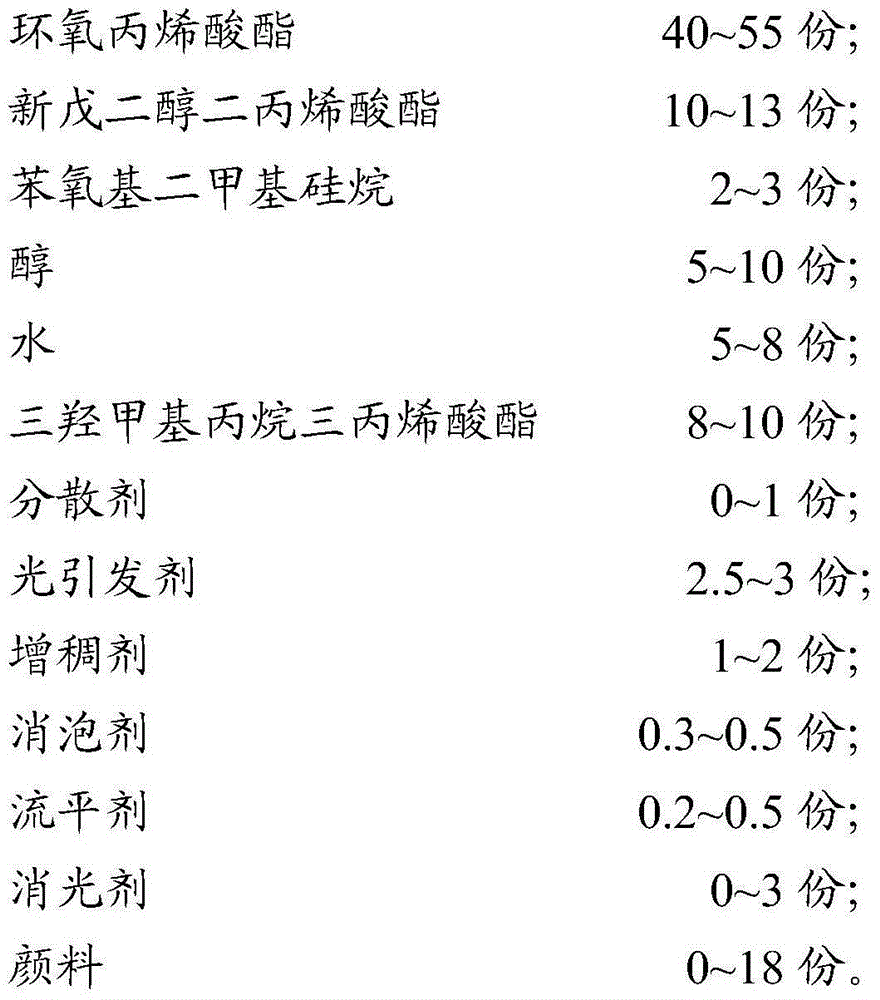

Method used

Image

Examples

Embodiment 1

[0046] Prepare materials: 55 parts by weight of epoxy acrylate (XY-B-350, Suzhou Xingye Chemical Industry Co., Ltd.), 10 parts by weight of TMPTA, 13 parts by weight of NPGDA, 5 parts by weight of isopropanol, 5 parts by weight of n-butanol, 3 parts by weight of photoinitiator-TPO , 1 part by weight of modified polyurea (BYK-420, German BYK), 0.5 part by weight of leveling agent (HX-5600, Huaxia Auxiliary), 0.5 part by weight of defoamer (HX-5041, Huaxia Auxiliary), 2 parts by weight of phenoxydimethylsilane (HY-F4011, Guangzhou Hengyu Chemical Industry Co., Ltd.), and 5 parts by weight of water.

[0047] Mix the above-mentioned components together, and after mixing evenly, the water-based UV coating is obtained.

[0048] Spray or flow-coat this water-based UV paint on the surface of plastic materials (PP or PVC, with a smooth surface and a gloss of 50-90GS), with a spraying amount of 150g-250g / square meter, pass through a UV curing machine, and dry. After drying, place it fo...

Embodiment 2

[0054] Prepare materials: 50 parts by weight of epoxy acrylate (XY-B-350, Suzhou Xingye Chemical Industry Co., Ltd.), 10 parts by weight of TMPTA, 13 parts by weight of NPGDA, 5 parts by weight of isopropanol, 3 parts by weight of n-butanol, matting agent (OK-412, Degussa, Germany) 3 parts by weight, sodium polyhydroxylate (HX-5300, Huaxia Auxiliaries) 1 part by weight, modified polyurea (BYK-420, Bicker, Germany) 2 parts by weight, photoinitiator-TPO2. 5 parts by weight, 0.2 parts by weight of leveling agent (HX-5600, Huaxia Auxiliary), 0.3 parts by weight of defoamer (HX-5041, Huaxia Auxiliary), phenoxydimethylsilane (HY-F4011, Guangzhou Heng Yu chemical industry) 2 weight parts, water 8 weight parts.

[0055] Mix epoxy acrylate, TMPTA, NPGDA and sodium polyhydroxylate in the above raw materials, add matting agent after mixing, disperse at high speed until the fineness is ≤25μm, and finally add the remaining components in the raw materials, and stir evenly to obtain Water-b...

Embodiment 3

[0059] Material preparation: 40 parts by weight of epoxy acrylate (XY-B-350, Suzhou Xingye Chemical Industry), 8 parts by weight of TMPTA, 10 parts by weight of NPGDA, 5 parts by weight of isopropanol, 3 parts by weight of matting agent (OK-520, Degussa, Germany) Parts, 18 parts by weight of titanium dioxide (R-900 DuPont), 1 part by weight of sodium polyhydroxylate (HX-5320, Huaxia Auxiliaries), 2 parts by weight of modified polyurea (BYK-420, German BYK), photoinitiated Agent-TPO2.5 parts by weight, leveling agent (HX-5610, Huaxia Auxiliaries) 0.2 parts by weight, defoamer (HX-5041, Huaxia Auxiliaries) 0.3 parts by weight, phenoxydimethylsilane (HY- F4011, Guangzhou Hengyu Chemical) 2 parts by weight, water 8 parts by weight.

[0060]Mix epoxy acrylate, TMPTA, NPGDA and sodium polyhydroxylate in the above raw materials, add matting agent after mixing, disperse at high speed until the fineness is ≤25μm, and finally add the remaining components in the raw materials, and stir e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com