UV (Ultraviolet) varnish and preparation method thereof

A modification and raw material technology, applied in the field of UV varnish and its preparation, can solve the problems of difficult surface coating, insufficient adhesion, UV varnish falling off, etc., to achieve enhanced physical properties, strong adhesion, and strong wear resistance. Effect

Active Publication Date: 2013-05-08

惠州市汇流实业有限公司

View PDF4 Cites 13 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, some substances, especially metal substances, have a smooth surface, and spraying UV coatings, due to insufficient adhesion, makes the spraying effect unsatisfactory

For example, magnesium alloy, its surface coating is more difficult, the sprayed UV varnish may fall off, which seriously affects the appearance effect, and loses the function of UV varnish protective film

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

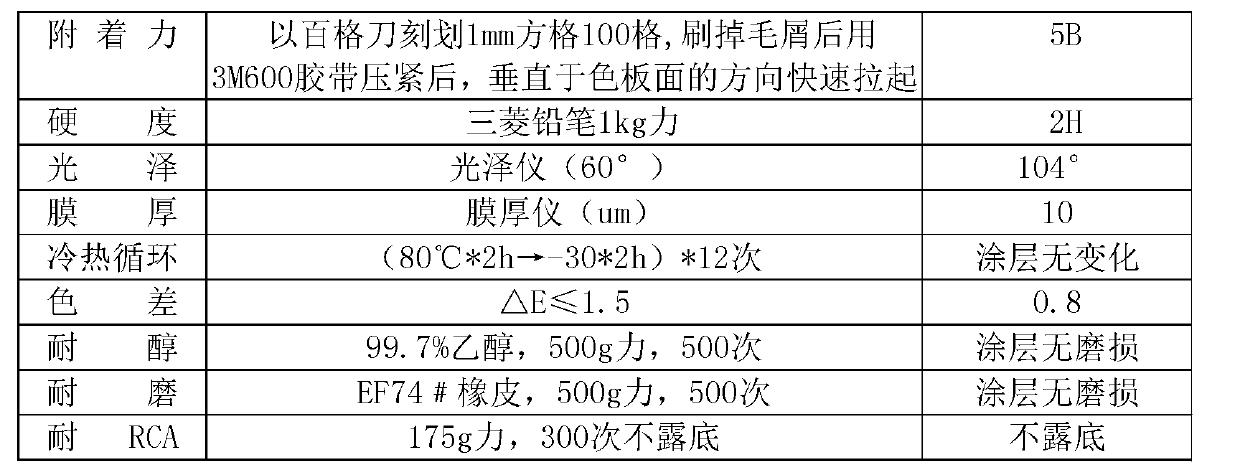

The invention discloses a UV (ultraviolet) varnish and a preparation method thereof. The UV varnish is composed of the following raw materials in parts by weight: 50-60 parts of polyurethane acrylate, 10-20 parts of epoxy acrylate, 10-15 parts of ethyl acetate, 8-10 parts of toluene, 2-4 parts of 1,6-hexandiol diacrylate, 2-3 parts of tripropylene glycol diacrylate, 2-4 parts of 1-hydroxy-cyclohexy-phenyl ketone, 1-2 parts of 2,4,6-trimethyl benzoyl ethyl phenyl phosphoinate, 1-2 parts of zinc dialkyl dithiophosphate, 0.8-1 part of poly(butyl acrylate), 0.8-1 part of ehtanediamine, 0.8-1 part of N-2-(aimno ethyl)-3-aminopropyl trimethoxy silane, 0.8-1 part of ehtanediamine tetramethylene phosphornic acid sodium salt, 0.3-0.5 part of plant ash, 3-5 parts of modified complexing agent, and 2-4 parts of light calcium carbonate. The paint produced by the method disclosed by the invention is strong in adhesive force, good in paint film hardness and gloss, and strong in cold-heat circulating resistance, alcohol resistance and wear resistance; and the physical property of the paint film is further enhanced by the added modified complexing agent and light calcium carbonate.

Description

Technical field The present invention mainly relates to a paint, in particular to a UV varnish and a preparation method thereof. Background technique UV coating has the advantages of fast curing speed, energy saving, normal temperature curing, superior performance, and environmental protection. It has fast glazing speed and high film brightness. After drying, the film surface is strong and heat resistant, which can make the surface of the substrate very bright and smooth. , Good refraction effect, make the substrate produce a strong sense of subject, has been widely used in chemical, machinery, electronics, light industry, communications and other fields. However, some materials, especially metal materials, have smooth surfaces and spray UV coatings. Due to insufficient adhesion, the spraying effect is not ideal. For example, magnesium alloy, its surface coating is more difficult, the sprayed UV varnish may fall off, which seriously affects the appearance effect, and loses th...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C09D175/14C09D163/00C09D7/12

Inventor 吕华

Owner 惠州市汇流实业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com