Optical diffusion film and manufacturing method thereof

A technology of optical diffusion and light diffusion, which is applied in optics, optical components, nonlinear optics, etc., can solve the problems of dazzling retina, high light transmittance, and easy agglomeration, so as to prevent irritation and damage, improve diffusion performance, and durable sex good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

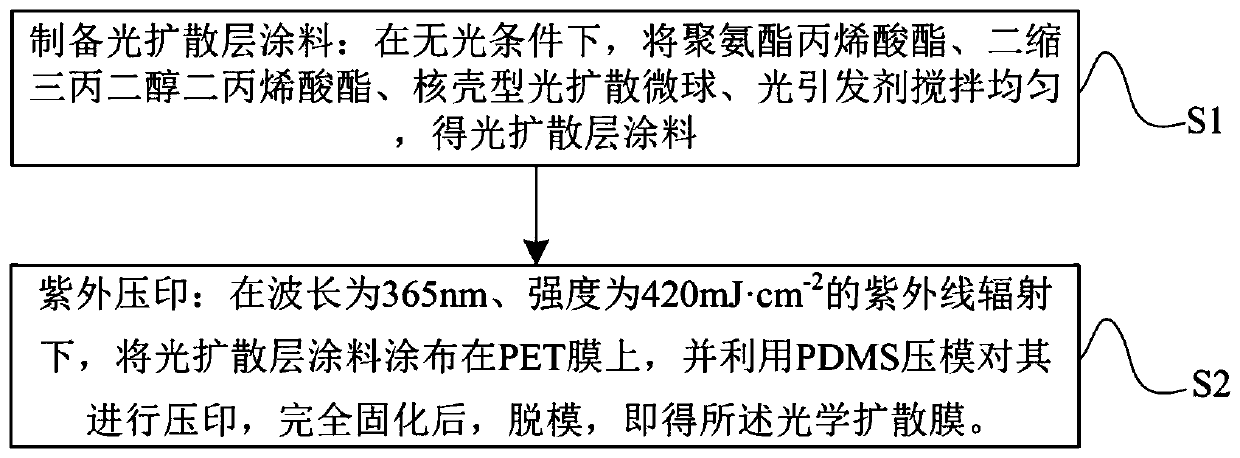

Method used

Image

Examples

Embodiment 1

[0027] S1: Preparation of core-shell light-diffusing microspheres: 0.5mol / L H 2 SO 4 Add the solution to 1000mL of 35% (v / v) ethanol solution, adjust the pH to 3.5, add 20mL of aminopropyltrimethoxysilane, 10mL of vinyltrimethoxysilane, 5mL of phenyltriethoxysilane, and magnetically Stir the reaction for 3 hours, then add 0.2mol / L NaOH solution to adjust the pH to 10, and continue the reaction for 3 hours to obtain a suspension of silicone microspheres;

[0028] Then add 1g Zn(NO 3 ) 2 ·6H 2 O, 2g Ce(NO 3 ) 3 ·6H 2 O, 1g Al(NO 3 ) 3 9H 2 O. 8g of hexamethylenetetramine, magnetically stirred for 0.5h, refluxed at 80°C for 3h, lowered to 40°C, added dropwise with 15mL glutaraldehyde for cross-linking modification for 1h, after cooling down to room temperature, centrifuged to collect the precipitate, and deionized Alternately washed twice with water and ethanol, and vacuum dried to obtain core-shell light-diffusing microspheres;

[0029] S2: Preparation of light-diffus...

Embodiment 2

[0032] S1: Preparation of core-shell light-diffusing microspheres: 1.5mol / L H 2 SO 4 Add the solution into 1000mL of 35-50% (v / v) ethanol solution, adjust the pH to 4.0, add 25mL of aminopropyltrimethoxysilane, 15mL of vinyltrimethoxysilane, and 7.5mL of phenyltriethoxysilane, Stir at 30°C for 4 hours, then add 0.5mol / L NaOH solution to adjust the pH to 10, and continue the reaction for 6 hours to obtain a suspension of silicone microspheres;

[0033] Add 1.5g Zn(NO 3 ) 2 ·6H 2 O, 2.5gCe(NO 3 ) 3 ·6H 2 O, 1.5gAl(NO 3 ) 3 9H 2 O. 10g of hexamethylenetetramine, magnetically stirred for 1h, refluxed at 80°C for 4h, lowered to 45°C, added dropwise with 20mL of glutaraldehyde for cross-linking modification for 1-2h, after cooling down to room temperature, centrifuged to collect the precipitate, and used Alternate washing with ionized water and ethanol for 2 to 3 times, and vacuum drying to obtain core-shell light-diffusing microspheres;

[0034] S2: Prepare the light-dif...

Embodiment 3

[0037] S1: Preparation of core-shell light-diffusing microspheres: 2mol / L H 2 SO 4 Add the solution to 1000mL of 35-50% (v / v) ethanol solution, adjust the pH to 4.5, add 30mL aminopropyltrimethoxysilane, 20mL vinyltrimethoxysilane, 10mL phenyltriethoxysilane, 40 ℃ magnetic stirring reaction for 6 hours, then add 1mol / L NaOH solution to adjust the pH to 10, and continue the reaction for 8 hours to obtain a suspension of silicone microspheres;

[0038] Then add 2g Zn(NO 3 ) 2 ·6H 2 O, 3g Ce(NO 3 ) 3 ·6H 2 O, 2g Al(NO 3 ) 3 9H 2 O. 10g of hexamethylenetetramine, magnetically stirred for 1h, refluxed at 80°C for 5h, lowered to 50°C, added dropwise with 30mL of glutaraldehyde for cross-linking and modified for 2h, after cooling down to room temperature, centrifuged to take the precipitate, and deionized water Alternately washed with ethanol for 3 times, and dried in vacuum to obtain core-shell light-diffusing microspheres;

[0039] S2: Preparation of light-diffusing laye...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com