Ink composition for ink-jet printing

An inkjet printing and composition technology, which is applied in the directions of inks, applications, household appliances, etc., can solve the problems of limiting the effective application of UV-curable inks, increasing production investment, increasing production costs, etc., so as to reduce inkjet production costs and improve inkjet printing. The effect of production efficiency

Active Publication Date: 2010-12-22

ZHUHAI FREE TRADE ZONE NEOJET APOLLOJET IMAGING MATERIALS

View PDF4 Cites 16 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, for large-area glass and ceramic surface spray painting, pre-implementing surface treatment or pre-coating requires a special site, such as a clean spraying workshop, and also requires special processing equipment or spray coating equipment, adding such a The pretreatment process limits the effective application of UV-curable ink to a large extent, and also increases production investment, which increases the overall production cost.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

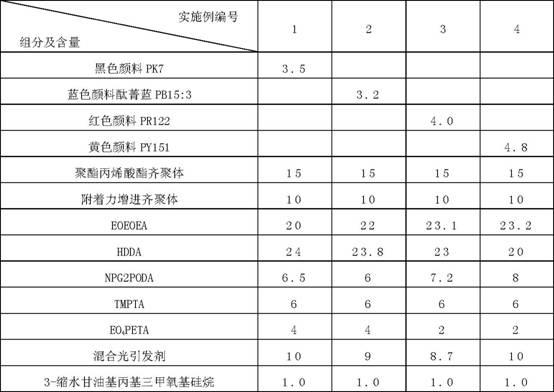

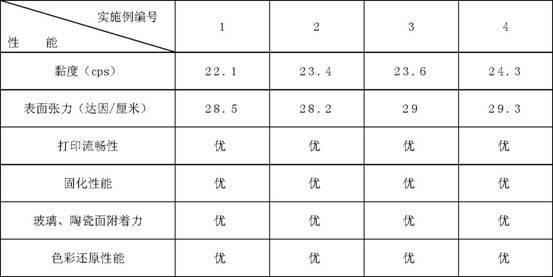

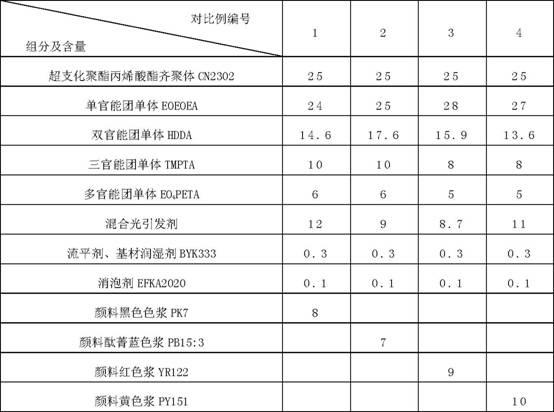

[0018] The ink composition for inkjet printing of the present invention will be described in detail below with reference to examples.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to an ink composition for ink-jet printing, which contains 10-35% by weight of at least one selected from polyurethane (methyl) acrylate oligomer and polyester acrylate oligomer, 5-20% by weight of adhesion promoting oligomer, 40-70% by weight of at least one selected form EOEOEA, THFA, IBOA, PHEA, HDDA, DPGDA, TPGDA, HEMA, TMPTA, EO3TMPTA, PO3TMPTA, EO4PETA and DPHA, 0.1-3% by weight of at least one selected from N-(beta-aminoethyl)-alpha-aminopropyltrimethoxysilane, methacrylate propyltrimethoxysilane, styrene chloro diamino silane and 3-glycidyl propyltrimethoxysilane and 2-6% by weight of paint. The ink composition is applicable to applying direct printing on an inorganic matter without being precoated, thereby simplifying the ultraviolet curing and spray printing process carried out on the surface of the inorganic matter, reducing the production cost and improving the production efficiency of inkjet printing.

Description

technical field [0001] The invention relates to an ink composition for inkjet printing, especially an inkjet ink composition for direct printing on the surface of inorganic materials such as glass and ceramics without surface pretreatment or precoating. Background technique [0002] In the inkjet industry, as the requirements for environmental protection become higher and higher, the application of traditional solvent-based inks is increasingly restricted, while the market for inkjet printing using UV-curable inks is gradually increasing. Compared with traditional solvent-based inks, UV-curable inks have greater advantages, and their water resistance and weather resistance are not weaker than solvent inks. At the same time, UV-curable inks have medium adaptability and wide range that solvent inks do not have , for ABS, PVC, PET, PP, PE, acrylic, etc., whether it is a sheet or a coil, it can be printed, and inorganic materials such as metal, ceramics, and glass can also be pr...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C09D11/10C09D11/30C09D11/40

Inventor 何迎胜

Owner ZHUHAI FREE TRADE ZONE NEOJET APOLLOJET IMAGING MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com