Thermosetting high flame retardant matte ink for pet substrates

A matte ink and thermosetting technology, applied in the field of ink, can solve the problems of PET materials that cannot be used in large scale, product performance degradation, damage to coating adhesion, etc., and achieve the effect of improving the interface effect, improving flame retardancy, and not easy to deteriorate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

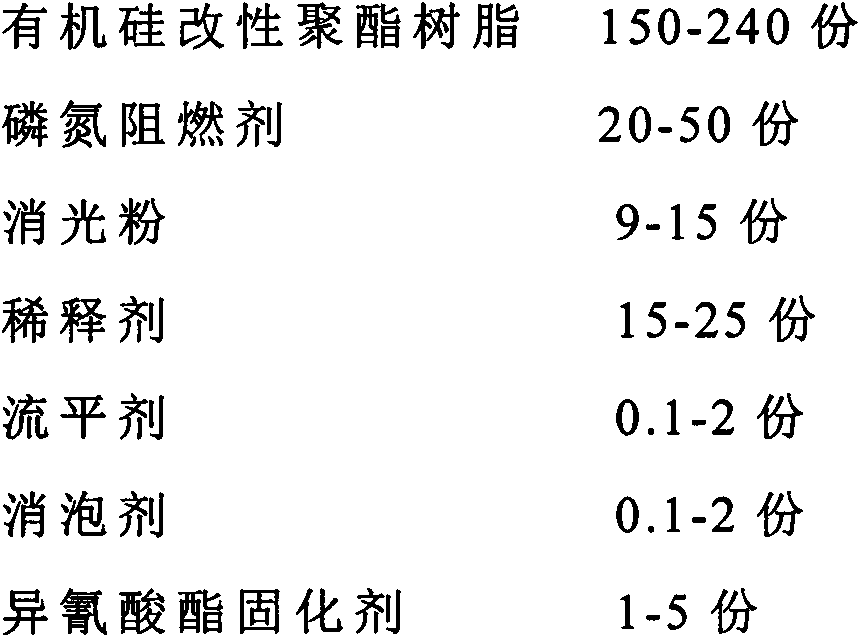

[0040] Mix 36g FR-TM-B flame retardant (Nantong New Jersey New Material Company), 100g of organosilicon modified polyester resin ES-008 and 80g of organosilicon modified polyester resin ES-0109P (Wuxi Huizhi Technology Co., Ltd. ), 12g matting powder OK-500 (Degussa) and 15g methyl ethyl ketone, 1500rpm high-speed dispersion for 30 minutes; 306 (German BYK Chemical Co., Ltd.), 800rpm low-speed dispersion for 10 minutes to obtain the main agent; add 2.5g HDI hardener TIN-22 (Deqian) and 5g methyl ethyl ketone to the main agent, stir evenly to obtain a transparent fluid, which is PET-based Materials with thermosetting high flame retardant matte ink.

Embodiment 2

[0042] Mix 30g FR-TM-B, 90g silicone modified polyester resin ES-008 and 70g silicone modified polyester resin ES-0109P, 10g matting powder Tosoh E-1011 and 18g butanone, 1500rpm high-speed dispersion 30 minutes; then add 0.6g leveling agent BYK-O54, 0.4g defoamer BYK-306, disperse at 800rpm for 10 minutes at low speed to obtain the main agent; add 3g HDI hardener TIN-22, 2g butanone into the main agent, stir Obtain transparent fluid uniformly, which is a thermosetting high flame retardant matte ink for PET substrates.

Embodiment 3

[0044] Mix 22g flame retardant FR-TM-B, 70g silicone modified polyester resin ES-008 and 100g silicone modified polyester resin ES-0109P, 11g matting powder Tosoh E-1011 and 10g butanone, 1500rpm high-speed dispersion for 30 minutes; then add 0.3g leveling agent BYK-O54, 0.5g defoamer BYK-306, 800rpm low-speed dispersion for 10 minutes to obtain the main agent; 2.9g HDI hardener Deqian TIN-22, 10g methyl ethyl ketone Add it to the main ingredient, stir it evenly to get a transparent fluid, which is a thermosetting high flame retardant matte ink for PET substrates.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com