Far infrared emission high-temperature-resistant kitchen and bath paint and preparation method thereof

A technology with far-infrared emission and high temperature resistance, which is applied in the direction of coating, etc., can solve the problems of poor persistent hydrophobicity, low far-infrared emission performance, easy migration of hydrophobic components, etc., and achieve excellent heat resistance and hydrophobicity, coating The effect of dense surface and improved far-infrared emission performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A kind of far-infrared emitting high temperature resistant transparent kitchen bathroom coating, its raw material is made up of A component 15wt%, B component 30wt%, leveling agent 0.5wt% and the solvent of balance, described leveling agent and solvent constitute C Components; the A component is composed of methyltrimethoxysilane, tetraethylorthosilicate and water, and the molar ratio of the methyltrimethoxysilane to tetraethylorthosilicate is 1:1.5 , the molar ratio of water and methyltrimethoxysilane is 1:0.05; the B component is composed of β-heptamethylsilylethyl trialkoxysilane, silicon carbide nanoparticles and water, silicon carbide nano The average particle size of the particles is 20nm, the particle size range is 10-45nm, and D90-D10 is 20m, the mass ratio of β-heptamethylsilylethyltrialkoxysilane to silicon carbide nanoparticles is 1:0.03, The molar ratio of water to β-heptamethylsilylethyltrialkoxysilane is 1:0.1.

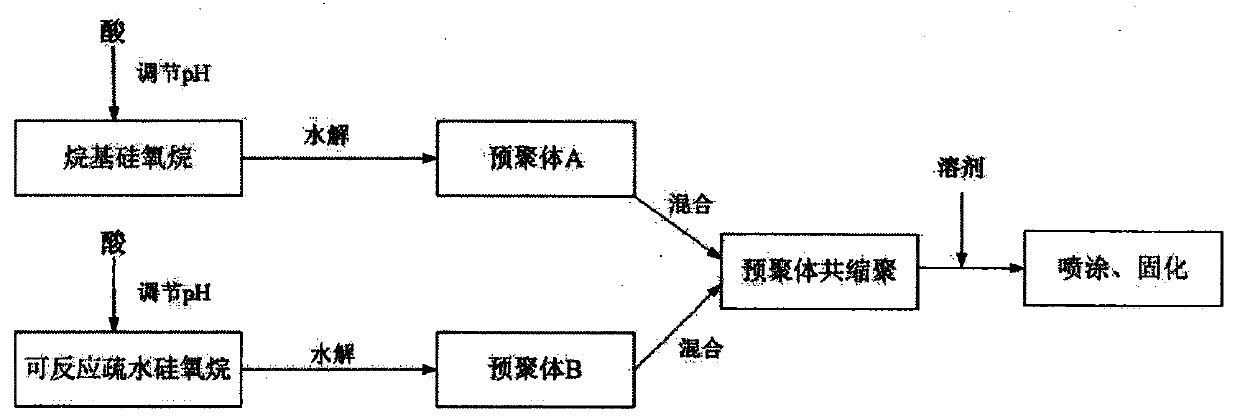

[0033] Such as figure 1 Shown, the prepar...

Embodiment 2

[0039] A far-infrared emitting high-temperature-resistant transparent kitchen and bathroom coating. Its raw materials are composed of 30wt% of component A, 30wt% of component B, 1wt% of leveling agent and the balance of solvent. The leveling agent and solvent constitute group C Divide; Described A component is made up of methyltriethoxysilane, tetraethyl orthosilicate and water, and the molar ratio of described methyltriethoxysilane and tetraethyl orthosilicate is 1: 0.25, the molar ratio of water and methyltriethoxysilane is 1:0.3; the B component is composed of β-heptamethylsilylethyltrialkoxysilane, silicon carbide nanoparticles and water, carbonized The average particle size of silicon nanoparticles is 50nm, the particle size range is 45-60nm, and D90-D10 is 12nm, and the mass ratio of β-heptamethylsilyl ethyl trialkoxysilane to silicon carbide nanoparticles is 1: 0.1, the molar ratio of water to β-heptamethylsilylethyltrialkoxysilane is 1:0.5.

[0040] Such as figure 1 ...

Embodiment 3

[0046] A kind of far-infrared emitting high temperature resistant transparent kitchen bathroom coating, its raw material is made up of A component 20wt%, B component 25wt%, leveling agent 0.5wt% and the solvent of balance, described leveling agent and solvent constitute C Components; the A component is composed of methyltrimethoxysilane, tetraethylorthosilicate and water, and the molar ratio of the methyltrimethoxysilane to tetraethylorthosilicate is 1:1 , the molar ratio of water and methyltrimethoxysilane is 1:0.1; the B component is composed of β-heptamethylsilylethyl trialkoxysilane, silicon carbide nanoparticles and water, silicon carbide nano The average particle size of the particles is 30nm, the particle size range is 15-45nm, and D90-D10 is 20nm, the mass ratio of β-heptamethylsilylethyltrialkoxysilane to silicon carbide nanoparticles is 1:0.05, The molar ratio of water to β-heptamethylsilylethyltrialkoxysilane is 1:0.2.

[0047] Such as figure 1 Shown, the preparat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| surface | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com