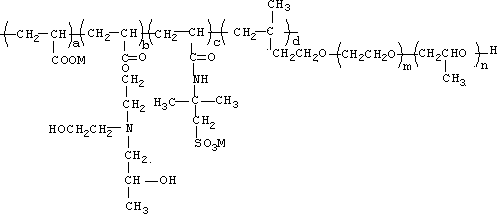

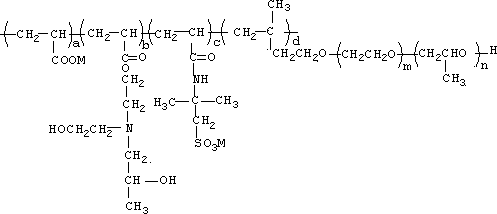

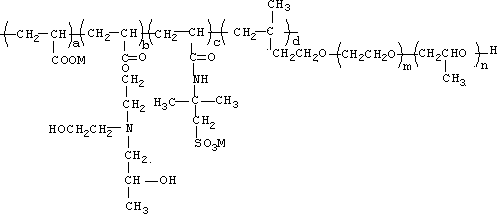

Ethers early strength type polycarboxylate water reducer and preparation method thereof

An early-strength polycarboxylate technology, which is applied in the field of ether-based early-strength polycarboxylate water reducers and their preparation, can solve the problems of reducing 28d strength, achieve superior early-strength performance, stable performance, and easy control of conditions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) Amidation reaction: Add 62g of diethanol monoisopropanolamine (DIEPA), 80g of methyl acrylate (or 85g of methyl methacrylate), and 2.5g of concentrated sulfuric acid into a four-necked flask, and start the stirring device, at 75 The temperature was kept at ℃ for 3 hours to obtain the amide small monomer.

[0027] (2) Copolymerization reaction: Weigh 5 g of amide small monomer, 2 g of 2-acrylamido-methylpropanesulfonic acid (AMPS) and 150 g of TPEG with a molecular weight of 1000, add them into a four-necked flask together with 200 g of water, and heat up to 55 ℃. Add the aqueous solution of ammonium persulfate (can also be replaced by potassium persulfate) (1.2g ammonium persulfate or potassium persulfate + 20g water) and the aqueous solution of thioglycolic acid (1.15g thioglycolic acid + 20g water) dropwise, and the dropping time is After 4 hours, the temperature was kept constant for 1.5 hours after the dropwise addition.

[0028] (3) Neutralization: cool down ...

Embodiment 2

[0031] (1) Amidation reaction: Add 65g of diethanol monoisopropanolamine (DIEPA), 90g of isooctyl acrylate, and 2.0g of p-toluenesulfonic acid into a four-neck flask, start the stirring device, and keep the temperature at 85°C for 3 hours. The amide small monomer is obtained.

[0032] (2) Copolymerization reaction: weigh 6g of amide small monomer, 2.5g of 2-acrylamido-methylpropanesulfonic acid (AMPS) and 160g of TPEG with a molecular weight of 2000, add them into a four-necked flask together with 190g of water, and heat up to 58°C. Add the aqueous solution of hydrogen peroxide (0.75g hydrogen peroxide + 25g water) and the aqueous solution of dodecyl mercaptan (1.05g dodecyl mercaptan + 25g water) respectively dropwise, the time for adding is 3 hours, and keep the temperature at 1.5 Hour.

[0033] (3) Neutralization: cool down to 40°C, adjust the pH value within the range of 6.0-7.0 with ammonia water (can also be replaced by calcium hydroxide, calcium oxide or ethanolamine)...

Embodiment 3

[0035] (1) Amidation reaction: Add 60g of diethanol monoisopropanolamine (DIEPA), 80g of maleic anhydride, 2.3g of sulfamic acid (can also be replaced by concentrated phosphoric acid or ethyl acetate) into a four-necked flask, start stirring The device was kept at a constant temperature of 100°C for 2 hours to obtain amide small monomers.

[0036](2) Copolymerization reaction: Weigh 5.5g of amide small monomer, 1.5g of 2-acrylamido-methylpropanesulfonic acid (AMPS) and 180g of TPEG with a molecular weight of 3000, add them into a four-necked flask together with 210g of water, and raise the temperature to 60°C. Add dropwise the aqueous solution of sodium azobisisobutyrimide hydrochloride (1.0g sodium azobisisobutyrimide hydrochloride + 20g water), 3-mercaptopropionic acid (you can also use isopropanol, sodium formate or 3-mercaptopropionic acid iso octyl ester) aqueous solution (1.25g 3-mercaptopropionic acid, isopropanol, sodium formate or 3-mercaptopropionic acid isooctyl es...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com