Polyelement composite heavy oil emulsion splitter and preparation method thereof

A technology of demulsifier and heavy oil, which is applied in the direction of dehydration/demulsification by chemical methods, water treatment and refining, etc. It can solve the problem that it is difficult for demulsifiers to purify impurities and high-efficiency demulsification, demulsifiers cannot meet the use requirements, and the difference of harmful impurities is very large Large and other problems, achieve good demulsification effect, clear oil-water interface, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

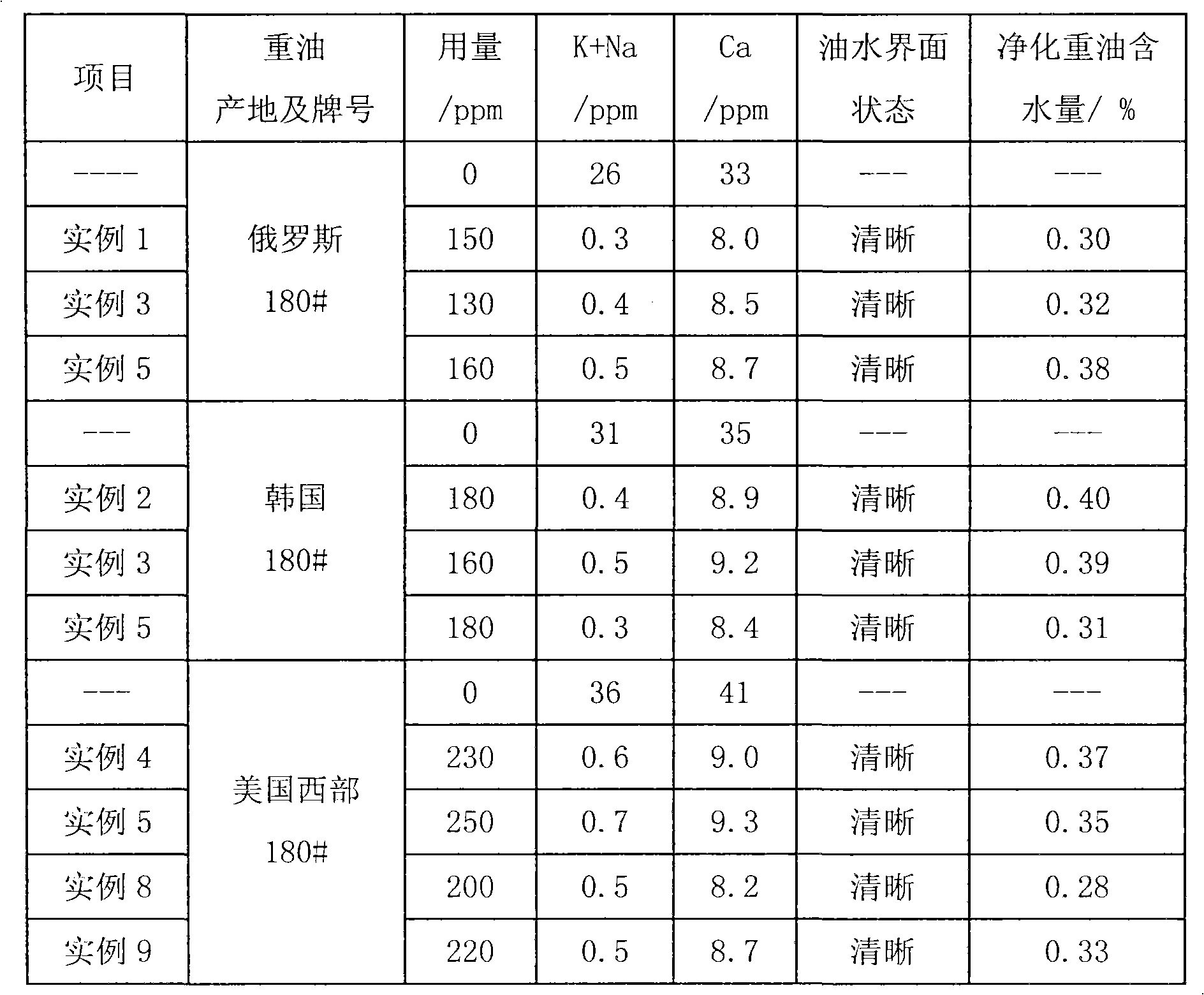

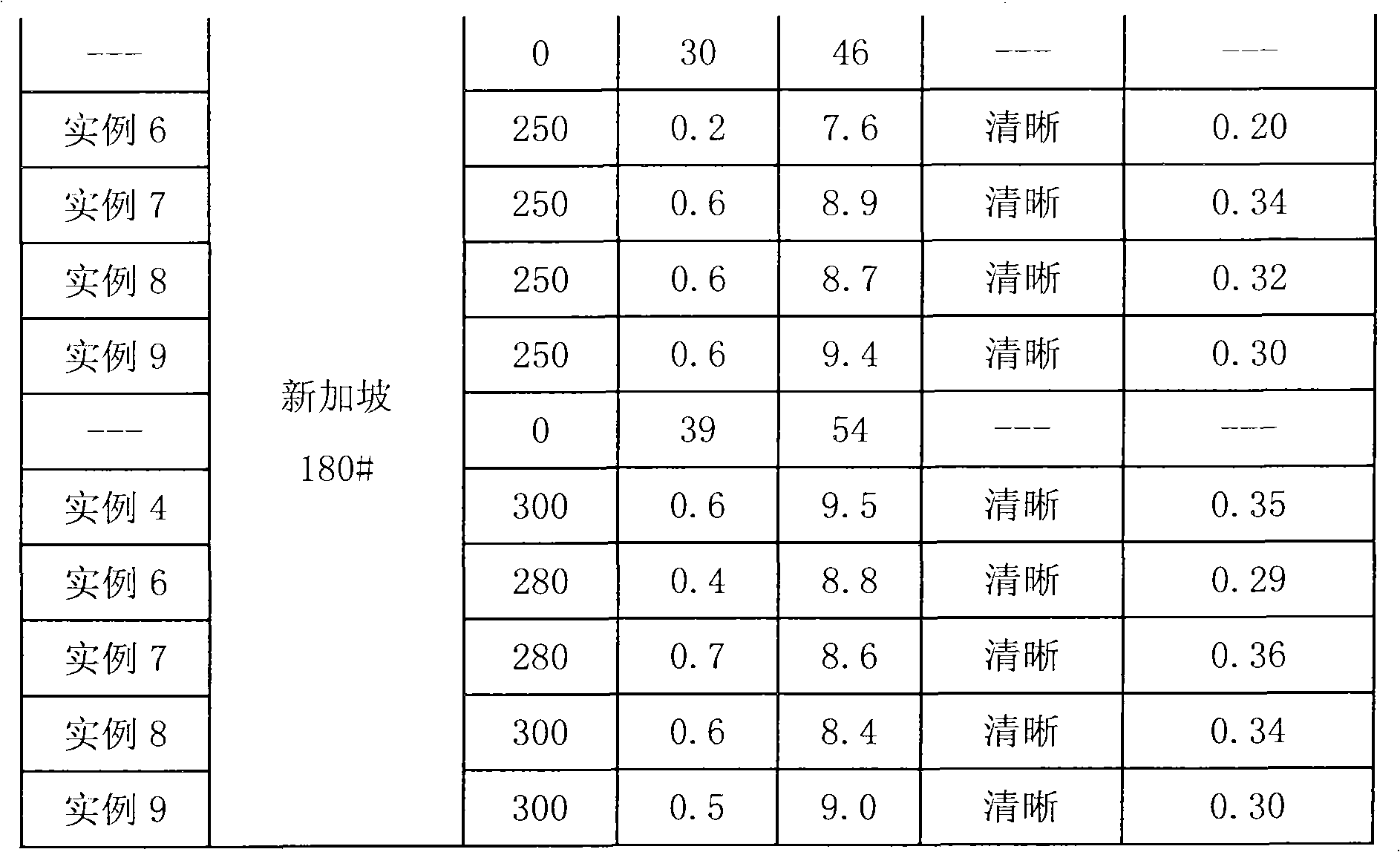

Examples

Embodiment 1

[0025] Add the initiator polyethylene polyamine and catalyst KOH into the pressure reactor, add propylene oxide (PO) dropwise, control the temperature at 120-140°C, and continue the reaction for 30 minutes after the pressure drops to less than 0.4MPa; open the pressure reactor, Add ethylene oxide (EO) dropwise, continue the reaction for 30 minutes after the pressure drops to less than 0.4MPa, lower the temperature, open the pressure reactor, adjust the pH value of the reactant to neutral with glacial acetic acid, and obtain polyethylene polyamine polyoxyethylene Polyoxypropylene ether.

[0026] Specific raw material ratios are shown in Table 1. The amount of KOH used is 0.3% of the total raw material mass to obtain polyethylene polyamine polyoxyethylene polyoxypropylene ether D1 and polyethylene polyamine polyoxyethylene polyoxypropylene ether D2 respectively.

[0027] The preparation raw material of table 1 polyethylene polyamine polyoxyethylene polyoxypropylene ether

[002...

Embodiment 2

[0030] Add initiator and catalyst KOH into the pressure reactor, add propylene oxide dropwise, control the temperature at 120-140°C, and continue the reaction for 30 minutes after the pressure drops to less than 0.4MPa; open the pressure reactor, add ethylene oxide dropwise, After the pressure drops to less than 0.4 MPa, continue to react for 30 minutes, lower the temperature, open the pressure reactor, and adjust the pH value of the reactant to neutral with glacial acetic acid to obtain fatty alcohol polyoxyethylene polyoxypropylene ether.

[0031] Specific raw material ratios are shown in Table 2. The dosage of the initiator is 0.3% of the total raw material mass to obtain polyethylene polyamine polyoxyethylene polyoxypropylene ether Z1 and polyethylene polyamine polyoxyethylene polyoxypropylene ether Z2 respectively.

[0032] The preparation raw material of table 2 fatty alcohol polyoxyethylene polyoxypropylene ether

[0033] Fatty alcohol polyoxyethylene polyoxypr...

Embodiment 3

[0035] Mix deionized water, acrylic acid, chain transfer agent isopropanol and initiator ammonium persulfate evenly, and place them in a water bath at 60-65° C. to react for 3-4 hours to obtain polyacrylic acid.

[0036] Specific raw material ratios are shown in Table 3, and polyacrylic acid B1 and polyacrylic acid B2 were obtained respectively.

[0037] The preparation raw material of table 3 polyacrylic acid

[0038] Polyacrylic acid

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com